Method for preparing sintered neodymium iron boron by adding nanometre aluminium powder

A nano-aluminum powder and NdFeB technology, applied in the field of rare earth magnetic materials, can solve problems such as limited resources, high mining costs, and performance degradation of NdFeB magnets Br, etc., and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

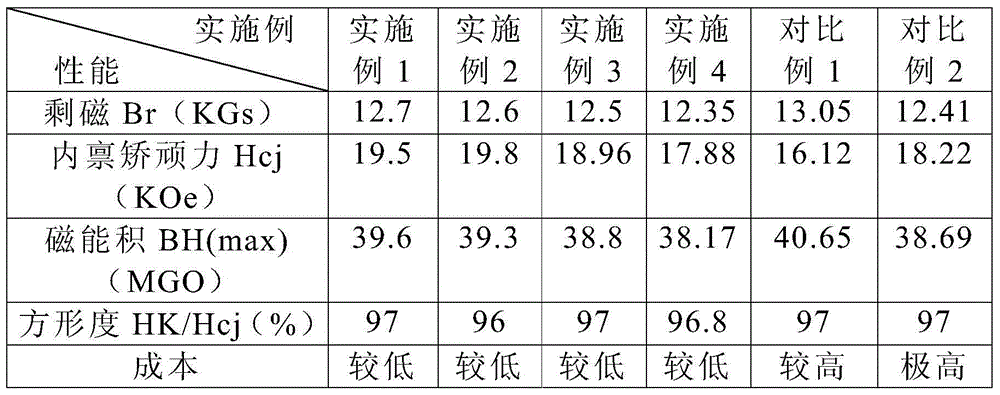

Examples

Embodiment 1

[0025] According to the following formula (PrNd) 30 Gd 1 co 1.0 Al 0.8 Cu 0.1 B 0.98 Fe bal (Mass percentage) Weigh the raw materials, and the raw materials that have been weighed are smelted at 1500 ° C in a vacuum quick-setting furnace with a vacuum degree of 0.5 Pa, and cast into flakes after the smelting is complete;

[0026] Put the above flakes in a hydrogen crushing furnace at 540°C for hydrogen crushing, hydrogen crushing for 4.5 hours to obtain a powder, and then use a jet mill to make a fine powder with an average particle size of 4 μm under the protection of nitrogen with an oxygen content of less than 200 ppm;

[0027] Add nano-aluminum powder with an average particle size of 50nm to the micropowder of NdFeB according to the ratio of 0.5wt%, and sieve through a sieve for a 200-mesh powder sieving machine after mixing evenly;

[0028] Put the sieved fine powder into the molding press mold under the protection of inert gas and apply a 1.5T magnetic field for or...

Embodiment 2

[0031] According to the following formula (PrNd) 30 Gd 1 co 1.0 Al 0.9 Cu 0.1 B 0.98 Febal (Mass percentage) Weigh the raw materials, and the raw materials that have been weighed are smelted at 1480 ° C in a vacuum quick-setting furnace with a vacuum degree of 0.6 Pa, and cast into flakes after the smelting is complete;

[0032] Put the above flakes in a hydrogen crushing furnace at 535°C for hydrogen crushing, hydrogen crushing for 4 hours to obtain a powder, and then use a jet mill to make a fine powder with an average particle size of 3.5 μm under the protection of nitrogen with an oxygen content of less than 200 ppm;

[0033] Add aluminum powder with an average particle size of 80nm to the micropowder of NdFeB according to the ratio of 0.3wt%, and sieve through a sieve for a 150-mesh powder sieving machine after mixing evenly;

[0034] Put the sieved fine powder into the molding press mold under the protection of an inert gas and apply a 1.6T magnetic field for orient...

Embodiment 3

[0037] According to the following formula (PrNd) 29 Gd 2 co 1.0 Al 0.9 Cu 0.1 B 0.98 Fe bal (Mass percentage) Weighing raw materials, the raw materials weighed are smelted at 1450°C in a vacuum quick-setting furnace with a vacuum degree of 0.3Pa, and cast into flakes after the smelting is complete;

[0038] Put the above flakes in a hydrogen crushing furnace at 550°C for hydrogen crushing, hydrogen crushing for 4 hours to obtain a powder, and then use a jet mill to make a fine powder with an average particle size of 5 μm under the protection of nitrogen with an oxygen content of less than 200 ppm;

[0039] Add aluminum powder with an average particle size of 10nm to the micropowder of NdFeB according to the ratio of 0.2wt%, and sieve through a sieve for a 300-mesh powder sieving machine after mixing evenly;

[0040] Put the sieved fine powder into the molding press mold under the protection of inert gas and apply a 2.0T magnetic field for orientation. After orientation, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com