Environment-friendly high-strength anti-deformation aluminum-clad heat preservation door and manufacturing method thereof

It is a technology with green environmental protection and production method, which is applied in the direction of door leaves, windows/doors, manufacturing tools, etc. It can solve the problems of poor airtightness, easy deformation, curling, and poor waterproof performance of thermal insulation doors, so as to prevent cracking, low price, The effect of good market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

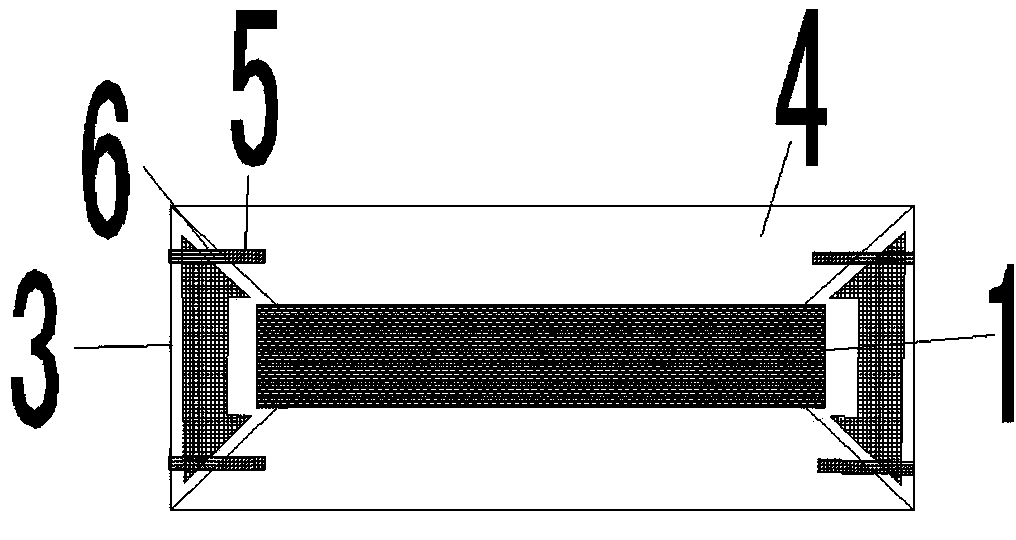

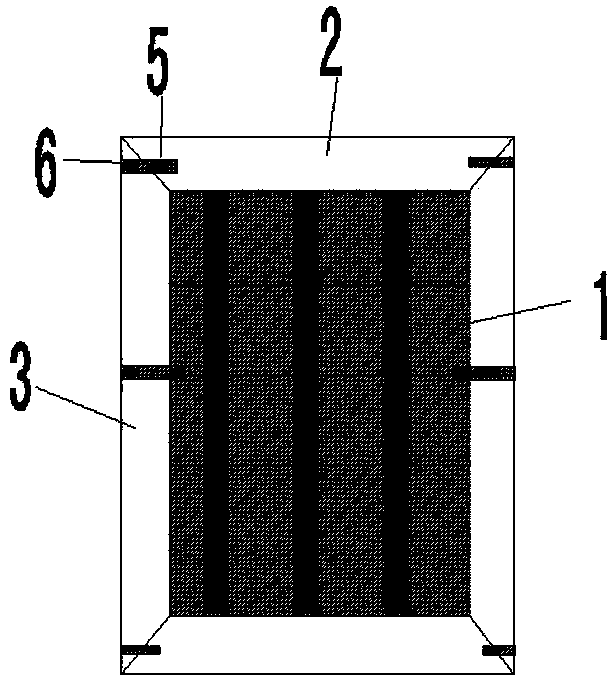

Image

Examples

Embodiment 1

[0029] A method for a green and environment-friendly high-strength anti-deformation aluminum-clad thermal insulation door, the method includes the following steps: the first step is to use a rotary cutter to cut the leftover environmentally friendly wood into veneers, divide the veneers into grades, and make the top-grade veneer for the surface layer and other grades of veneer as the middle layer, and then dry the veneer to a moisture content below 12%; coat the surface layer and the middle layer that need to be bonded with an environmentally friendly E0 grade glue with a concentration of 70%, and press them together to form a composite Board, cut the composite board into laths of the same specification, and the surface of the laths to be bonded is coated with an environmentally friendly E0 grade glue with a concentration of 70%;

[0030] The second step is to choose three layers of horizontally textured slats, place a layer of horizontally textured slats in the middle, and pla...

Embodiment 2

[0033] The method for the green, environment-friendly, high-strength and anti-deformation aluminum-clad thermal insulation door described in this embodiment, the first step is to cut the leftover environmentally friendly wood into veneers with a rotary cutter, and select the first-level veneer, the second-level veneer, and the third-level veneer. The boards are stored in different categories, high-quality veneers are used on the surface, other grades of veneers are used as the middle layer, and then the veneers are dried with a drum or a vacuum dryer to a moisture content of 6-12%; the surface layer and the middle layer need to be bonded The surface is coated with environmentally friendly E0 grade glue with a concentration of 70%. The glue is vegetable glue with zero formaldehyde emission or E0 grade melamine glue or phenolic glue; pressed to make a composite board, and the laminated composite board is fine-tuned After sawing into slats of the same specification, 100% of the cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com