Electrostatic spraying nano-cobweb waterproof moisture-permeable film and preparation method thereof

A waterproof and moisture-permeable membrane, electrostatic spraying technology, applied in protective clothing, clothing, textiles and papermaking, etc., can solve the problems of low porosity, small coverage area, inability to meet waterproof and moisture-permeable, and achieve good structural integrity, increase The effect of coverage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing an electrostatically sprayed nano-spider web waterproof and moisture-permeable membrane, the specific steps are:

[0028] (1) Dissolve calcium chloride in deionized water, and ultrasonic for 1 hour, then dissolve the polyurethane emulsion in deionized water containing calcium chloride, and stir continuously for 5 hours with a magnetic stirring device to prepare a uniform and stable Emulsion; in the uniform emulsion, the mass concentration of the polyurethane emulsion is 40%, and the content of calcium chloride is 0.01% of the total mass of the emulsion; the conductivity of the emulsion is 0.05mS / cm, and the surface tension is 10mN / cm;

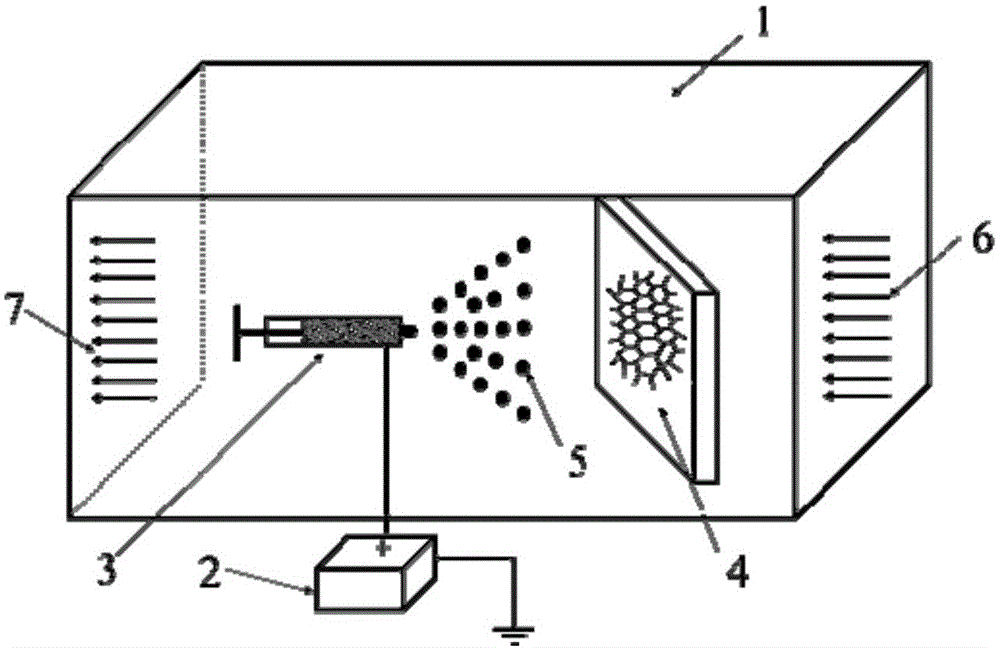

[0029] (2) Spray using the electrostatic spray box 1 shown in the accompanying drawings, first pour the emulsion into the spray pipe through the electrostatic spray liquid supply system and the spray needle 3, the receiving substrate 4 is fabric, and the receiving distance is 10cm;

[0030] (3) Turn on the high-vol...

Embodiment 2

[0032] A method for preparing an electrostatically sprayed nano-spider web waterproof and moisture-permeable membrane, the specific steps are:

[0033] (1) Add sodium chloride to deionized water, and ultrasonic for 3 hours, then dissolve the polyacrylate emulsion in deionized water containing sodium chloride, place the above emulsion on a magnetic stirrer and stir continuously for 8 hours , be mixed with uniform, stable emulsion; In described homogeneous emulsion, the mass concentration of polyacrylate emulsion is 35%, and the content of sodium chloride is 15% of total mass of emulsion, and the conductivity of described emulsion is 4mS / cm , the surface tension is 50mN / cm.

[0034] (2) Use the electrostatic spray box 1 shown in the accompanying drawing to spray, first pour the emulsion into the spray pipe through the electrostatic spray liquid supply system and spray needle 3, the receiving substrate is metal mesh, and the receiving distance is 15cm;

[0035] (3) Turn on the h...

Embodiment 3

[0037] A method for preparing an electrostatically sprayed nano-spider web waterproof and moisture-permeable membrane, the specific steps are:

[0038] (1) Lithium chloride is added to deionized water, and ultrasonic for 6 hours, then the polystyrene emulsion is dissolved in deionized water containing lithium chloride, and the above emulsion is placed on a magnetic stirrer and continuously stirred for 6 hours , be mixed with uniform, stable emulsion; In described homogeneous emulsion, the mass concentration of polystyrene emulsion is 30%, and the content of lithium chloride is 1% of emulsion gross mass, and the conductivity of described emulsion is 4.1mS / cm, the surface tension is 26mN / cm.

[0039] (2) Use the electrostatic spray box 1 shown in the accompanying drawing to spray, first pour the emulsion into the spray pipe through the electrostatic spray liquid supply system and the spray needle 3, the receiving substrate is cellulose paper, and the receiving distance is 50cm;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water pressure | aaaaa | aaaaa |

| Moisture flux | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com