A composite capsule wall phase change energy storage microcapsule and its preparation method

A phase-change energy storage and microcapsule technology, which is applied in the field of preparation of phase-change energy storage microcapsules, can solve problems such as overcooling and unfavorable microcapsule popularization and application, and achieve difficult reunion, favorable production costs, and good fusion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Take 100 parts of deionized water and 0.5 parts of styrene-maleic anhydride polymer sodium salt, put them in a 500mL three-necked flask, and stir continuously at room temperature for 20min to form a uniform solution;

[0033] (2) Take 5 parts of tetraethyl orthosilicate and 250 parts of deionized water, mix and stir evenly, add 0.2mol / L dilute hydrochloric acid to adjust the pH value of the system to 2, and carry out hydrolysis reaction at 50°C to obtain a silica-containing precipitate the suspension;

[0034] (3) Weigh 1 part of cetyl palmitate, 10 parts of sodium polyacrylate and 0.1 part of organically modified carbon nanofibers with phase transition temperature and phase transition latent heat value of 50 °C and 180 kJ / kg, respectively, at 60 °C Stir and react for 30 minutes to obtain a uniformly dispersed emulsion;

[0035] (4) Add the emulsion containing the phase change material to the solution containing the sodium salt of styrene-maleic anhydride polymer, ...

Embodiment 2

[0039] In Example 1, the number of parts of sodium polyacrylate was increased to 20 parts, and other operating methods and material compositions were kept unchanged, and a phase change energy storage microcapsule B of the present invention was obtained.

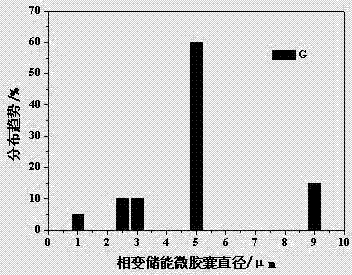

Embodiment 3

[0041] In Example 1, the number of parts of tetraethyl orthosilicate was increased to 10 parts, and its operation method and material composition remained unchanged, and a kind of phase change energy storage microcapsule C of the present invention was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com