A kind of energy-saving and environment-friendly asphalt and its preparation process

An energy-saving and environment-friendly asphalt technology, applied in building insulation materials, building components, climate change adaptation, etc., can solve the problems of exacerbating environmental damage, non-renewable resource consumption, white garbage that cannot be recycled, and damage to the road performance of the mixture. Achieve the effect of reducing friction, increasing viscosity and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

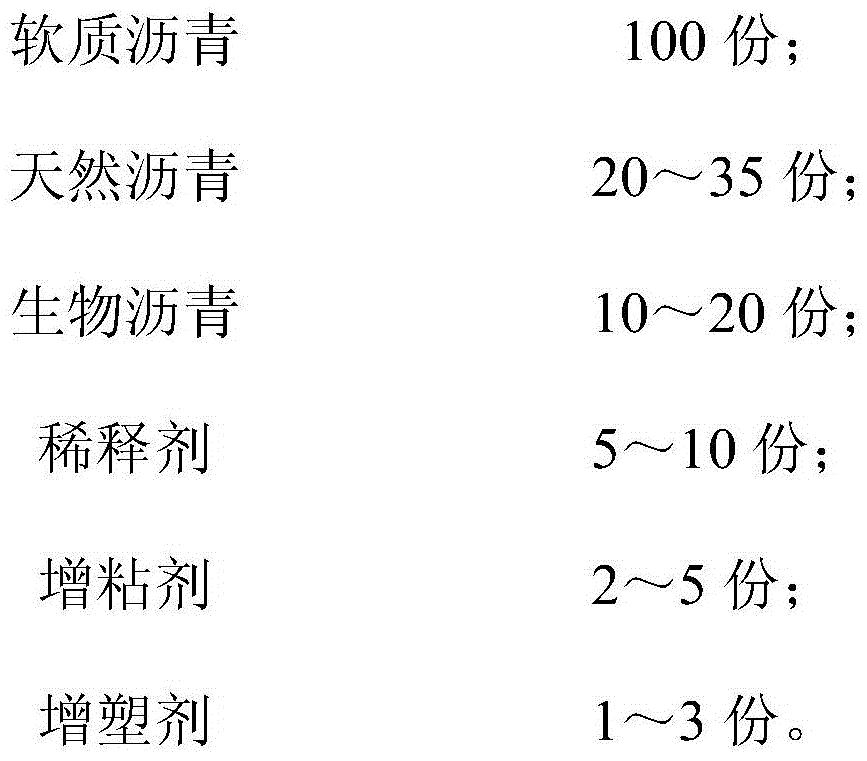

[0045] An energy-saving and environment-friendly asphalt, comprising the following raw materials in parts by weight: 100 parts of 130# matrix asphalt, 20 parts of rock asphalt, 15 parts of biological asphalt, 5 parts of diluent, and the diluent is vegetable oil, 3 parts of polyamide resin As a tackifier, 2 parts powdered cellulose as a plasticizer.

[0046] The environment-friendly asphalt of the present embodiment is prepared according to the following steps:

[0047] 1) In parts by weight, 15 parts of bio-asphalt, 3 parts of tackifier and 2 parts of plasticizer were mixed in sequence and stirred evenly to obtain mixture A;

[0048] 2) Take 100 parts of 130# base asphalt and heat it up to 140°C, heat it to a molten state, then pour the molten 130# base asphalt into the stirring equipment with a rotation speed of 300-500r / min;

[0049] 3) Add 5 parts of diluent to the 130# base asphalt in the mixing equipment, and fully stir to obtain the mixture B;

[0050] 4) Add 20 parts ...

Embodiment 2

[0055] A kind of energy-saving and environment-friendly asphalt, in parts by weight, comprises the following composition raw materials: 100 parts of 110# matrix asphalt, 25 parts of Trinidad (TLA) lake asphalt, 10 parts of biological asphalt, 6 parts of waste lubricating oil As diluent, 3 parts tackifier, 3 parts plasticizer.

[0056] Among them, the tackifier adopts a mixture of 1 part of epoxy resin and 2 parts of polyurethane, and the plasticizer adopts 0.5 part of waste rubber powder, 1 part of waste plastic, 0.5 part of powdered cellulose, 0.5 part of powdered styrene-butadiene rubber SBR and 0.5 part of powder A blend of thermoplastic styrene-butadiene rubber SBS.

[0057] The environment-friendly asphalt of the present embodiment is prepared according to the following steps:

[0058] 1) In parts by weight, 10 parts of bio-asphalt, 3 parts of tackifier and 3 parts of plasticizer were mixed in sequence and stirred evenly to obtain mixture A;

[0059] 2) Take 100 parts o...

Embodiment 3

[0066] A kind of energy-saving and environment-friendly asphalt, in parts by weight, comprises the following composition raw materials: 100 parts of 160# matrix asphalt, 30 parts of Trinidad (TLA) lake asphalt, 20 parts of biological asphalt, 9 parts of diluent, 5 parts 1 part tackifier, 3 parts waste plastic as plasticizer.

[0067] Wherein the diluent adopts the mixture of 8 parts of waste oil and 1 part of turpentine, and the tackifier adopts the mixture of 2 parts of polyurethane and 3 parts of petroleum resin.

[0068] The environment-friendly asphalt of the present embodiment is prepared according to the following steps:

[0069] 1) In parts by weight, 20 parts of bio-asphalt, 5 parts of tackifier and 3 parts of plasticizer were mixed in sequence and stirred evenly to obtain mixture A;

[0070] 2) Take 100 parts of 160# base asphalt and heat it up to 150°C, heat it to a molten state, then pour the molten 160# base asphalt into the stirring equipment with a rotation spee...

PUM

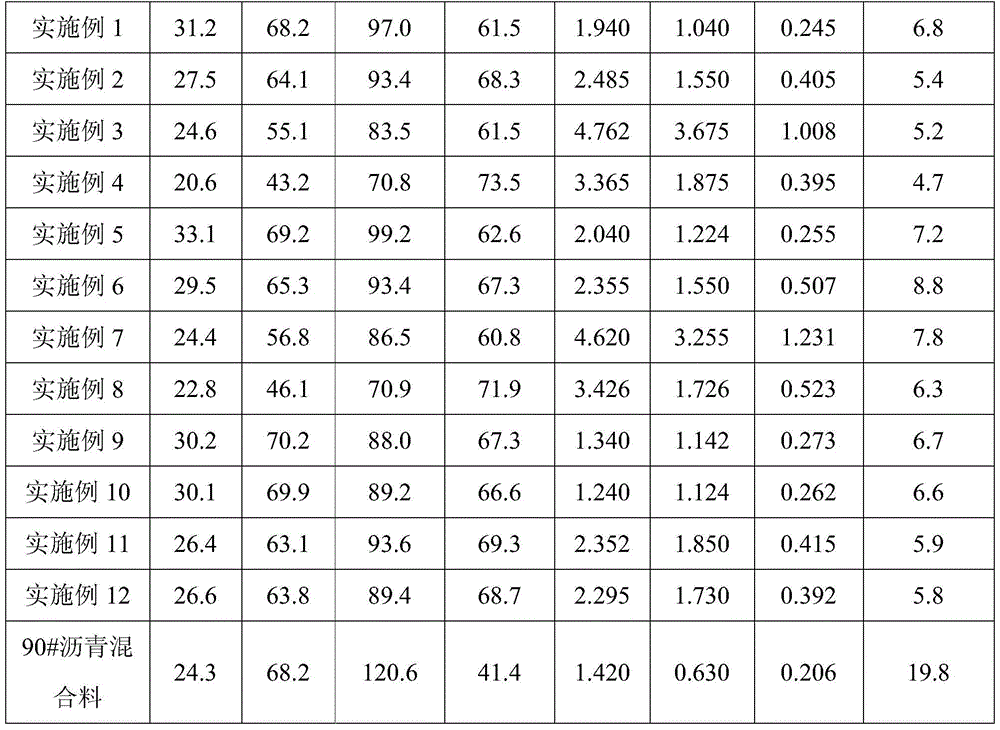

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com