Polyurethane elastomer containing polyether polyol/nano-SiO2 hybrid material

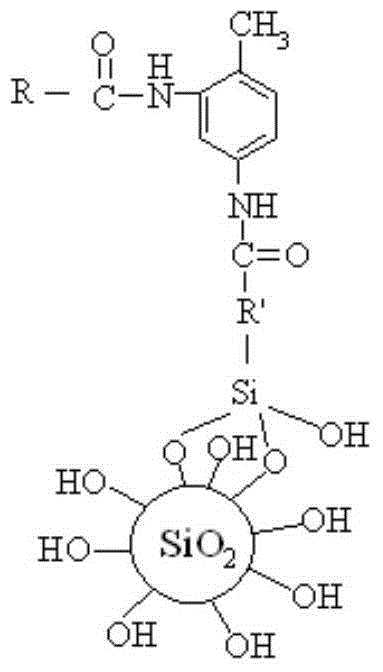

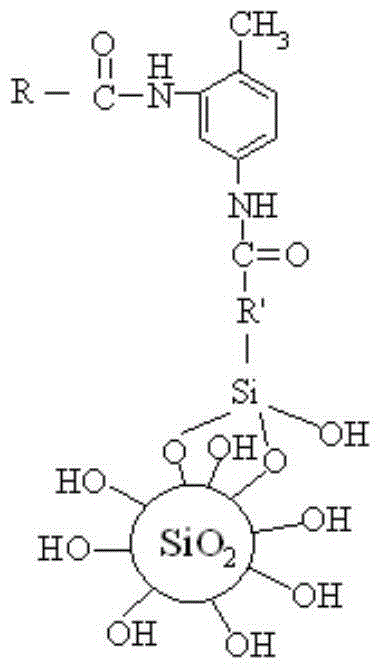

A polyurethane elastomer and polyether polyol technology, applied in the field of polyurethane materials, can solve the problems of poor interface compatibility between inorganic nanomaterials and polymers, difficulty in improving the performance of polyurethane composite materials, weak bonding, etc., and achieve modified performance Improve the elongation at break and reduce the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1: Preparation of Polyurethane Elastomer Containing Polyether Polyol / Nano Silica Hybrid Material

[0050] (1) Preparation of polyoxypropylene ether triol N330 / nano silica hybrid material

[0051] a. Under the protection of nitrogen, add 10g of γ-aminopropyltriethoxysilane dropwise into the mixture of 7.9g of toluene diisocyanate and 50g of anhydrous toluene with a dropping funnel, and mechanically stir at 20°C for 0.5 hours , add 135g polyoxypropylene ether trihydric alcohol N330, 0.5g stannous octoate, stir and react at 70°C for 6h, then rotary evaporate at 70°C, remove toluene, and obtain polymer A.

[0052] b. Disperse 10 g of nano-silicon dioxide in 100 g of toluene and sonicate for 0.5 h to obtain a nano-silicon dioxide dispersion.

[0053] c. 15g of polymer A, 11g of nano-silica dispersion, 1g of distilled water, and 100g of toluene were stirred and reacted at 60°C for 6 hours, and then rotary evaporated at 70°C to remove toluene and water to obtain polyo...

Embodiment 2

[0056] Embodiment 2: Preparation of polyurethane elastomer containing polyether polyol / nanometer silicon dioxide hybrid material

[0057] (1) Preparation of polyoxypropylene ether triol JH-3030 / nano silica hybrid material

[0058] a. Under the protection of nitrogen, add 10g of γ-aminopropyltrimethoxysilane dropwise into a mixture of 14g of diphenylmethane-4,4'-diisocyanate and 50g of anhydrous toluene with a dropping funnel, at 40°C After stirring mechanically for 1 hour, add 167g polyoxypropylene ether trihydric alcohol JH-3030 and 0.05g dibutyltin dilaurate, stir and react at 75°C for 4h, and then rotary evaporate at 70°C to remove toluene to obtain the polymer Object A.

[0059] b. Disperse 10 g of nano-silicon dioxide in 100 g of toluene and sonicate for 1 hour to obtain a nano-silicon dioxide dispersion.

[0060] c. 56g Polymer A, 30g nano-silica dispersion, 4g distilled water, 200 mass parts toluene, stirred and reacted at 70°C for 6 hours, then rotary evaporated at 7...

Embodiment 3

[0063] Embodiment 3: Preparation of polyurethane elastomer containing polyether polyol / nanometer silicon dioxide hybrid material

[0064] (1) Preparation of polyoxypropylene ether triol MN-3050 / nano silica hybrid material

[0065] a. Under the protection of nitrogen, add 10g N-β (aminoethyl)-γ-aminopropyltrimethoxysilane dropwise to the mixed solution of 10g isophorone diisocyanate and 50g anhydrous toluene with a dropping funnel , after mechanically stirring at 30°C for 2 hours, add 135g of polyoxypropylene ether triol MN-3050, 0.3g of lead octoate, stir and react at 80°C for 4h, and then rotary evaporate at 70°C to remove toluene to obtain a polymer a.

[0066] b. Disperse 10 g of nano-silicon dioxide in 100 g of toluene and sonicate for 2 hours to obtain a nano-silicon dioxide dispersion.

[0067] c. 31g of polymer A, 22g of nano-silica dispersion, 2g of distilled water, and 150g of toluene were stirred and reacted at 60°C for 8 hours, and then rotary evaporated at 70°C t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com