Toluene Methanol Side Chain Alkylation Method

A technology of alkylation and methanol, applied in chemical instruments and methods, organic chemistry, molecular sieve catalysts, etc., can solve the problems of rapid catalyst deactivation and poor stability, and achieve the effect of improving catalytic effect and ion exchange degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take silicon aluminum than SiO 2 / Al 2 o 3 =2.19 NaX molecular sieve 10 grams, under 80 ℃, carry out ion exchange in the potassium nitrate solution of 100 milliliters 1 mol / liter for 2 hours, exchange 3 times. Then carry out ion exchange in 50 ml of 1 mol / L cesium nitrate solution, exchange 3 times, filter and dry at 100° C. for 10 hours. Using europium nitrate as a precursor, metal europium is loaded on the modified molecular sieve obtained above by impregnation method to obtain a catalyst Eu / KCsX containing 1% europium.

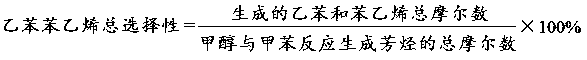

[0024] The catalyst obtained above is pressed into pellets of 40 to 60 meshes, put into a reactor, and placed in a reactor at normal pressure with a molar ratio of toluene to methanol of 5 and 2.5 hours. -1 liquid space velocity, 415°C, N 2 The activity evaluation is carried out under the condition that the flow rate is 10 ml / min, and the methanol utilization can be kept at 31% after continuous reaction for 200 hours, and the total selectivity of...

Embodiment 2

[0026] Same as [Example 1], only the exchange order of potassium and cesium is changed. At 80° C., ion exchange was carried out in 100 ml of 1 mol / L cesium nitrate solution for 2 hours and exchanged 3 times. Then carry out ion exchange in 50 ml of 1 mol / L potassium nitrate solution, exchange 3 times, filter and dry at 100° C. for 10 hours. Using europium nitrate as a precursor, metal europium is loaded on the modified molecular sieve obtained above by impregnation method to obtain a catalyst Eu / CsKX containing 1% europium.

[0027] After continuous reaction for 200 hours, the utilization rate of methanol can be kept at 28%, and the total selectivity of ethyl styrene and styrene is 97%.

Embodiment 3

[0029] Take silicon aluminum than SiO 2 / Al 2 o 3=2.19 NaX molecular sieve 10 grams, under 80 ℃, carry out ion exchange in the potassium nitrate solution of 100 milliliters 1 mol / liter for 2 hours, exchange 3 times. Then carry out ion exchange in 50 ml of 1 mol / L cesium nitrate solution, exchange 3 times, filter and dry at 100° C. for 10 hours. Using gadolinium nitrate as a precursor, metal gadolinium is loaded onto the modified molecular sieve obtained above by an impregnation method to obtain a catalyst Gd / KCsX containing 1% gadolinium.

[0030] The above-mentioned obtained catalyst tablet molding 40 ~ 60 mesh granular catalyst, put into the reactor, under normal pressure, the molar ratio of toluene to methanol is 5, in 2.5 hours -1 liquid space velocity, 415°C, N 2 The activity evaluation is carried out under the condition that the flow rate is 10 ml / min, and the methanol utilization can be kept at 31% after continuous reaction for 200 hours, and the total selectivity o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com