Preparation method of superfine scandium oxide nano powder

A technology of nano-powder and scandium oxide, applied in the field of nano-materials, can solve problems such as difficult large-scale production, difficulty in filtration and washing, precipitation and pollution, and achieve low cost, simple and easy preparation process, and high dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention relates to a kind of Yb 3+ doped Sc 2 o 3 Preparation method of nanopowder. The nanometer powder has small particle size and uniform particle size distribution (25-50nm), less agglomeration and high sintering activity, which is very beneficial to the preparation of highly dense transparent ceramics. Sc prepared from the above powder 2 o 3 The transmittance of base transparent ceramics is close to the theoretical value, and has broad application prospects in ultrafast laser materials, infrared window materials, scintillation materials and other fields. The synthesis method involved in the invention has the characteristics of simplicity, novelty, low cost and high efficiency.

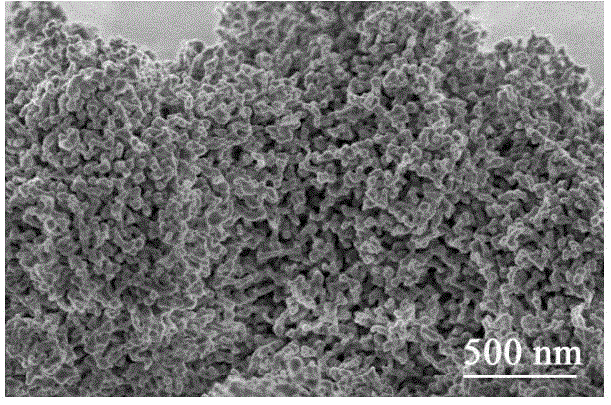

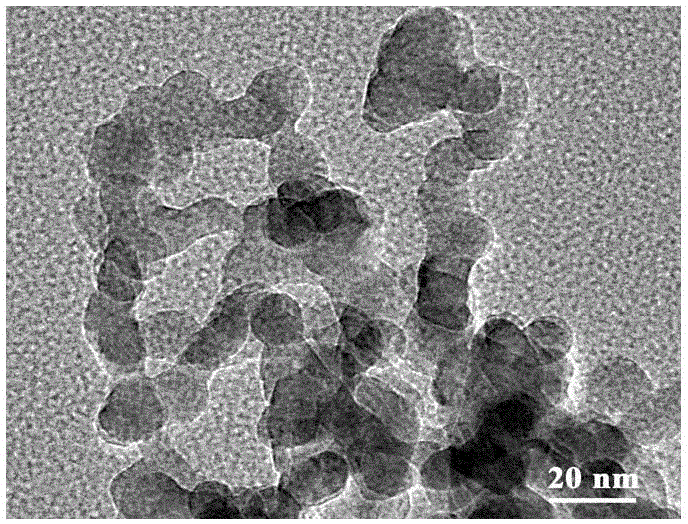

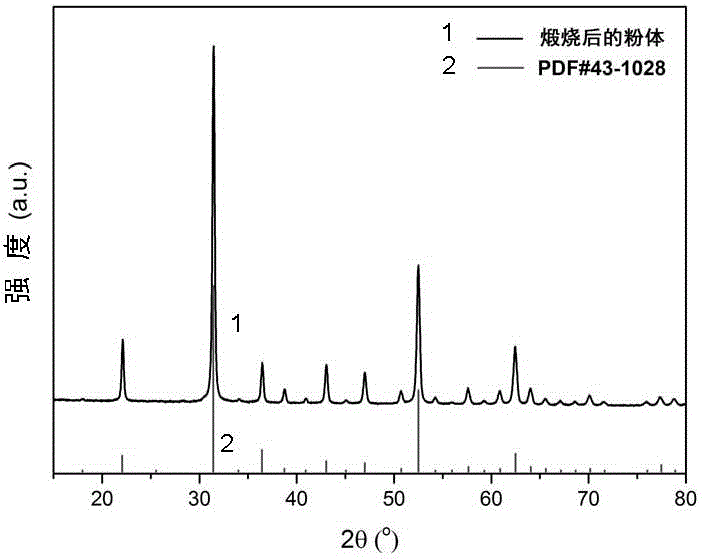

[0043] figure 1 The superfine Yb that is the gained of embodiment 1 3+ Scanning electron microscope (SEM) photographs of doped scandium oxide nanopowders. As can be seen from the photo: the prepared Yb 3+ The particle size of the doped scandium oxide nanopowder is 25-...

Embodiment 1

[0048] With chemical formula (Yb x sc 1-x ) 2 o 3 Weigh high-purity (99.99%) Yb 2 o 3 and Sc 2 o 3 A total of 0.030mol, dissolved in concentrated nitric acid (analytical pure) at 70 ° C, continue heating to evaporate excess nitric acid and water. Add 1600 mL of water, 400 mL of ethanol, and 1 mol of urea (analytical grade), and add 0.5 g of ammonium sulfate (analytical grade) as a dispersant to each 100 mL of the mixed solution, and stir for 2 hours. Placed in an oven at 90°C for 10 h. Finally, centrifuge, pour off the supernatant, add 800mL deionized water and stir for 45min, and then continue to centrifuge. Repeat the above operation 4 times with water, and repeat the operation 2 times with absolute ethanol. The final precursor was dried in an oven at 70 °C for 24 h. Pass through a 200-mesh sieve and calcinate at 1100°C for 4 hours in the air to obtain Yb 3+ :Sc 2 o 3 Nano powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com