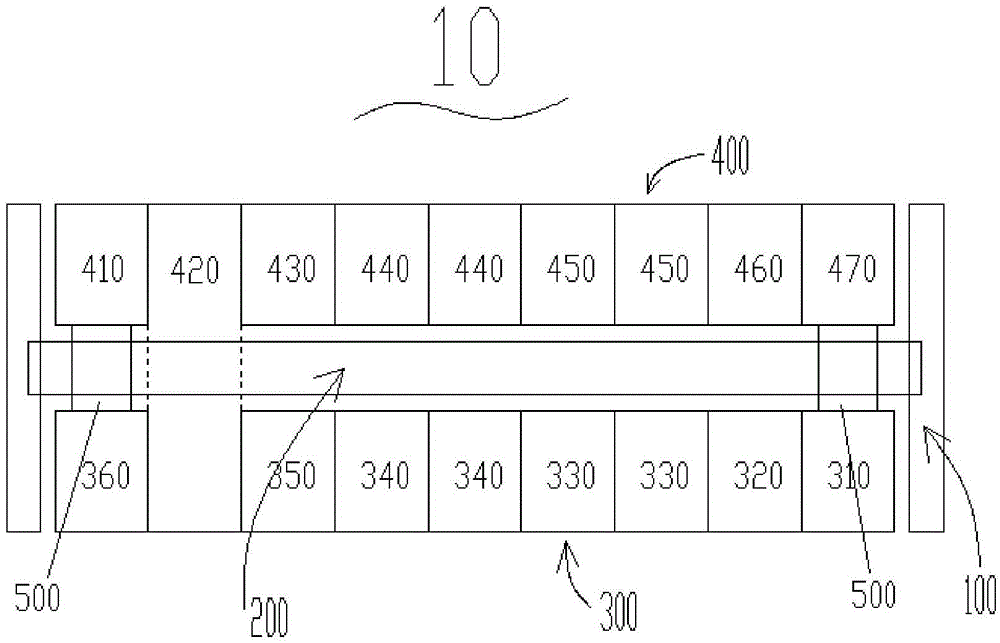

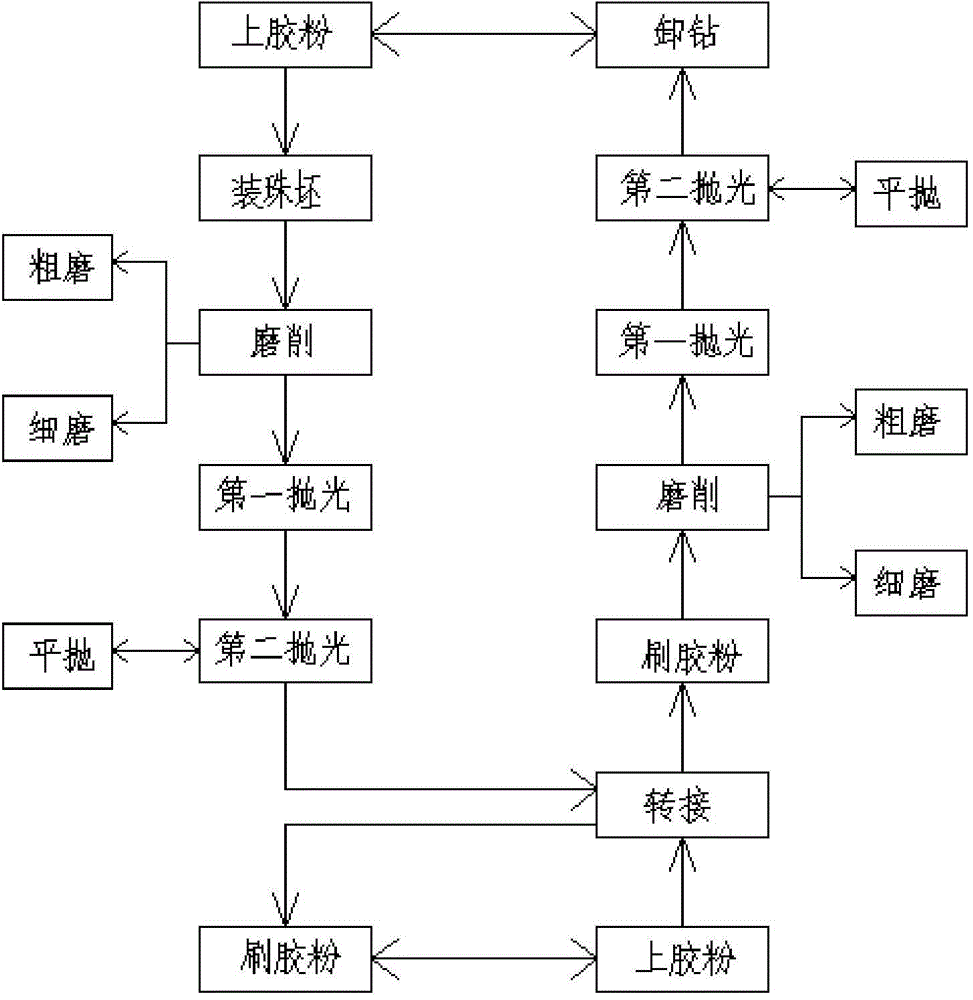

Full-automatic water drill grinding-polishing machine and processing technique thereof

A grinding and polishing machine, fully automatic technology, applied in the direction of grinding workpiece supports, metal processing equipment, grinding machine parts, etc., can solve the problems of waste products, low efficiency, poor rotation of fixture needles, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

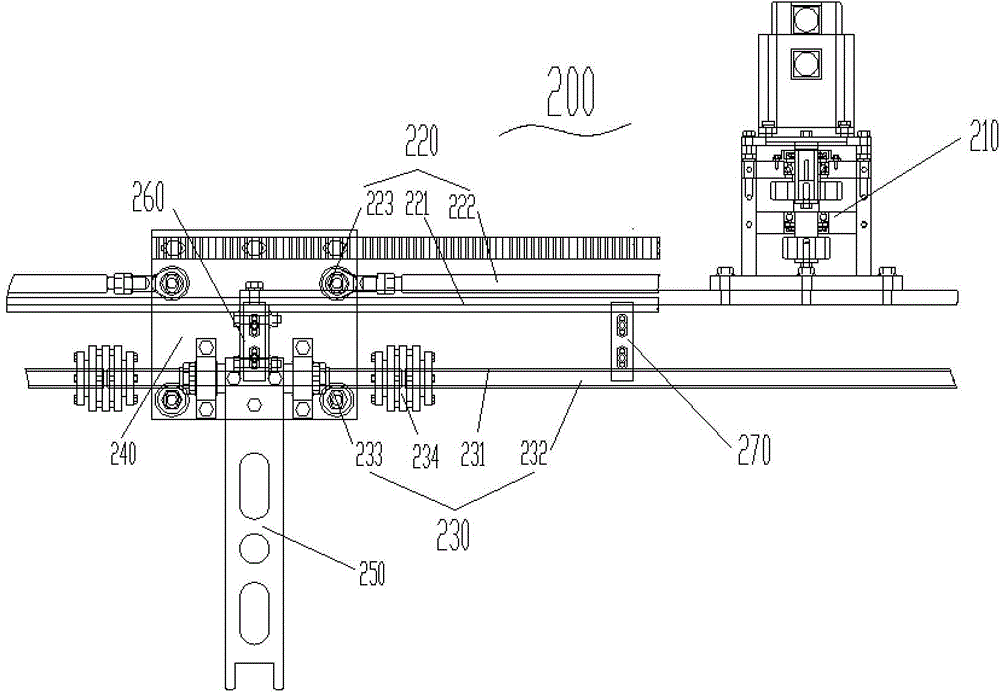

Embodiment Construction

[0047] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0048] In the description of the present invention, it needs to be understood that "motor", "the first feed motor", "the first indexing motor", "dressing motor", "swing motor", "drive motor", "the second feed motor" ", "the second indexing motor" and "powder brushing motor"; and "lift angle cylinder", "the first vertical cylinder", "horizontal cylinder", "scraper cylinder", "the second vertical cylinder", " Drive cylinder " and " cylinder " are for the convenience of describing the present invention and simplified description, rather than referring to the specific motor and cylinder that must be possessed in each station of this rhinestone grinding and polishing machine an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com