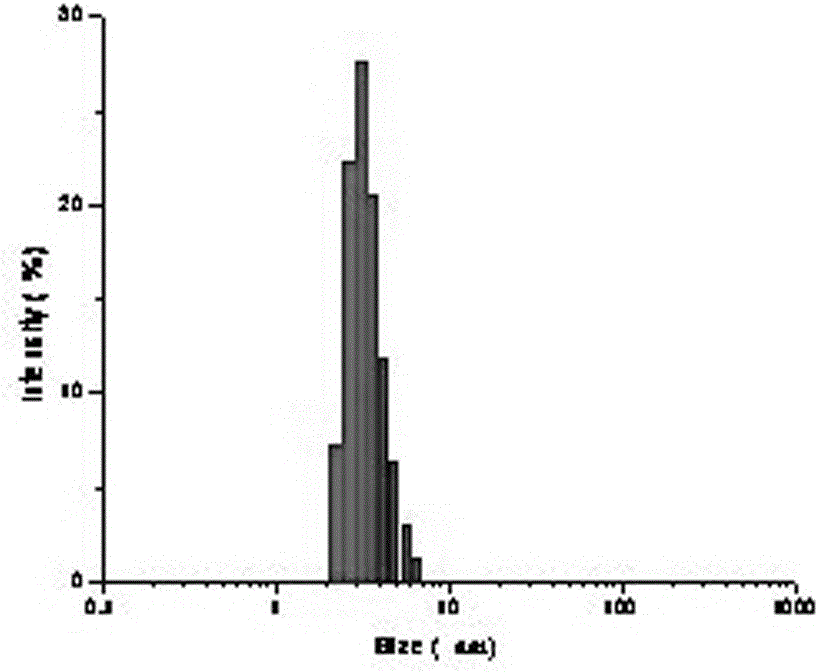

A kind of method that uses short amylose as template to prepare water-soluble nano-silver

A short amylose and water-soluble technology, which is applied in the field of preparing water-soluble nano-silver, can solve the problems of large diameter, reduced stability of aqueous solution, and uneven growth, and achieve the effects of short reaction time, easy operation, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

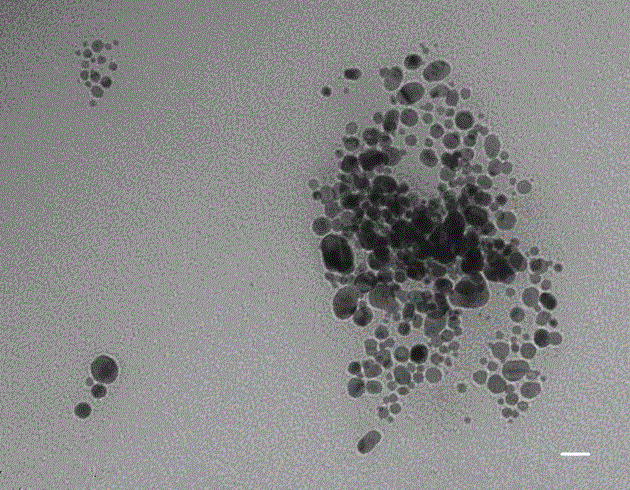

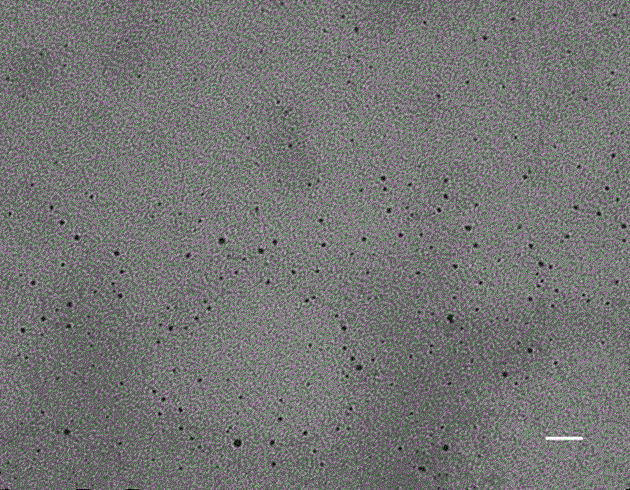

Image

Examples

Embodiment 1

[0023] A method for preparing water-soluble nano-silver with short amylose as a template, the steps are:

[0024] Preparation of buffer solution: Accurately weigh 3.27 g of disodium hydrogen phosphate and 2.24 g of citric acid, dissolve in 200 mL of distilled water, stir to fully dissolve, and set aside; pullulanase pretreatment: accurately weigh 1 mL of pullulanase Drop into 50 mL of distilled water, stir to make it fully mixed, and set aside; prepare starch milk: weigh 15 g of waxy rice starch and add it to 100 mL of buffer solution to obtain a 10% starch emulsion; the pH range of the buffer solution is 4.6 ~4.8;

[0025] Gelatinization: bath the prepared starch milk in water at 100°C for 20 minutes to completely gelatinize the starch, and then lower the temperature to 58°C (the optimum temperature of pullulanase); enzymatic hydrolysis: add treatment For good pullulanase, hydrolyze for 6 h; centrifuge at low speed: centrifuge the obtained solution at a speed of 3000 r / min f...

Embodiment 2

[0028] Preparation of buffer solution: Accurately weigh 3.27 g of disodium hydrogen phosphate and 2.24 g of citric acid, dissolve in 200 mL of distilled water, stir to fully dissolve, and set aside; pullulanase pretreatment: accurately weigh 1 mL of pullulanase Drop into 50 mL of distilled water, stir to make it fully mixed, and set aside;

[0029] Preparation of starch milk: Weigh 20 g of waxy corn starch and add it to 100 mL of buffer solution to prepare a 10% starch emulsion; gelatinization: put the prepared starch milk in a water bath at 100 °C for 25 min to completely gelatinize the starch, then cool down to 60 ℃; enzymatic hydrolysis: add the treated pullulanase to the gelatinized colloidal solution, and enzymatically hydrolyze for 5 hours;

[0030] Low-speed centrifugation: centrifuge the obtained solution at a speed of 3000 r / min for 4 minutes while it is hot to remove long amylose; inactivate the enzyme: continue heating to raise the temperature to 100 °C and keep it ...

Embodiment 3

[0033] Preparation of buffer solution: Accurately weigh 3.27 g of disodium hydrogen phosphate and 2.24 g of citric acid, dissolve in 200 mL of distilled water, stir to fully dissolve, and set aside; pullulanase pretreatment: accurately weigh 1 mL of pullulanase Drop into 50 mL of distilled water, stir to make it fully mixed, and set aside;

[0034] Preparation of starch milk: weigh 15 g of taro starch and add it to 100 mL of buffer solution to obtain a 10% starch emulsion; gelatinization: put the prepared starch milk in a water bath at 100 °C for 20 min to completely gelatinize the starch, then cool down to 58 °C ;Enzymolysis: add the treated pullulanase to the gelatinized colloid solution, and enzymolysis for 6 h; low-speed centrifugation: centrifuge the obtained solution at 3000 r / min for 3 min while it is hot, to remove long Amylose; Enzyme inactivation: Continue heating to raise the temperature to 100°C and keep it for 10 minutes to completely inactivate the enzyme, then c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com