A method and device for producing caustic soda by electrolysis of light brine instead of part of refined brine

A technology for salt water purification and light salt water, applied in the electrolysis process, electrolysis components, energy input and other directions, can solve the problems of low NaCl decomposition rate, large amount of long-term circulation, high production cost, high utilization rate, increased usage, and ratio reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

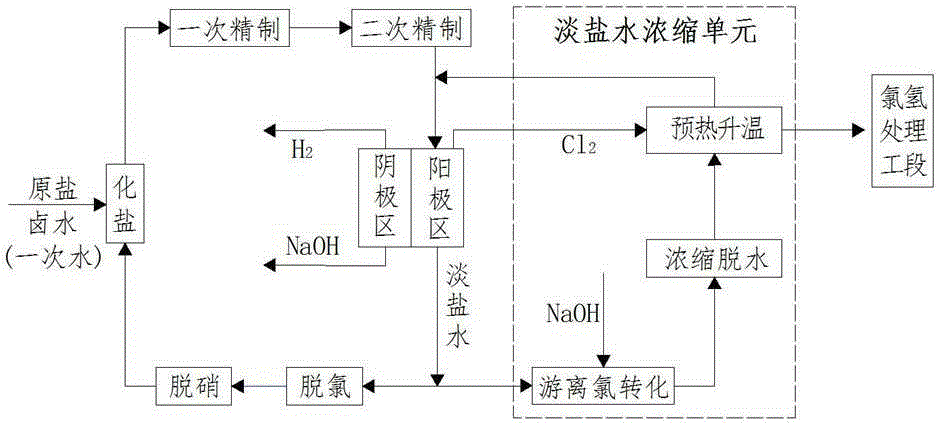

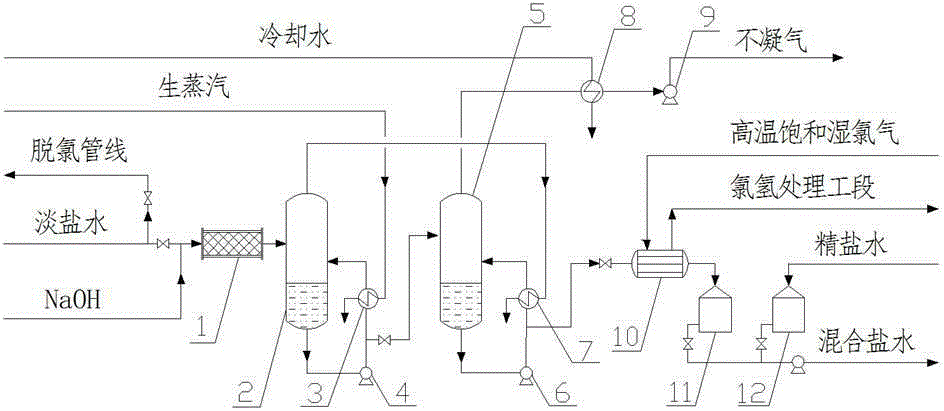

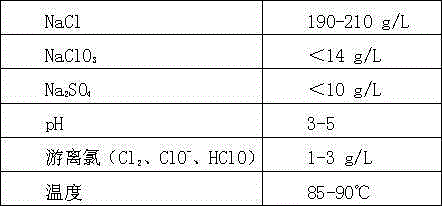

[0045] as attached figure 1 Shown, a kind of light brine of the present invention replaces the method for the electrolysis of part of refined brine to produce caustic soda, this method divides the light brine out of the tank into two parts in proportion according to the production needs, one part is dechlorinated and denitrified, and the desalinated water refining unit is used, and the other part Desalinated brine reuse unit, in which the ratio of dechlorination and denitrification desalination refining unit is determined according to the content of impurity ions in the brine entering the tank. Under the premise that the brine entering the tank is qualified, the desalination refining unit after dechlorination and denitrification should be minimized Ratio, in general, the industry can refer to the desalinated water refining unit after dechlorination and denitrification: the ratio of desalinated brine reuse unit (by mass fraction) is 1:3 to 1:4.

[0046] The brine refining unit ...

Embodiment 2

[0073] Example 2 is the same as Example 1, except that in order to further reduce energy consumption in actual production, the standard for reusing light brine in the above step 2) refers to increasing the NaCl content to 255-265g / L and reusing light brine After being mixed with raw refined brine, the content of impurity ions is consistent with the known secondary brine quality standard.

Embodiment 3

[0075] Example 3 is the same as Example 1-2, except that in order to further reduce energy consumption in actual production, the brine standard for entering the tank in the above step 4) means that the NaCl content contained therein is 285-295g / L, and the remaining impurities The ion content is consistent with the known secondary brine quality standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com