Synthesis method of Fe-Si-C ceramic precursor

A technology of ceramic precursor and synthesis method, which is applied in the field of synthesis of precursor highly branched polyferrocenyl silane, can solve the problems of affecting the processing performance of the precursor, solubility reduction, insolubility, etc., and is suitable for large-scale production, The effect of high ceramic productivity and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

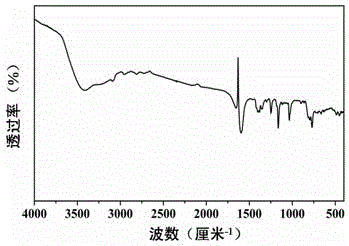

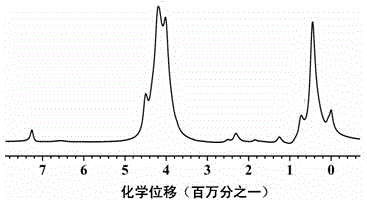

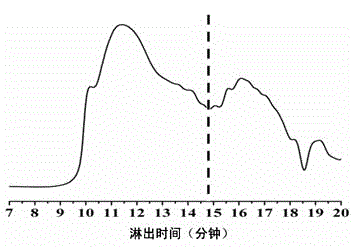

Image

Examples

reference example 1

[0040] Reference example 1: the preparation of ferrocene lithium salt:

[0041] Vacuumize the synthesis reaction system, replace high-purity nitrogen to normal pressure, repeat 3 times; add 10 g (53.8 mmol) ferrocene and 70 mL of anhydrous n-hexane solvent into a dry 250 mL reaction bottle, stir; then add 10 mL (66.7 mmol) of tetramethylethylenediamine; after stirring evenly, add 53 mL of n-hexane solution with a molar concentration of n-butyllithium of 2.4 mol / L dropwise, stir, and react for 10 h; filter under reduced pressure, remove the filtrate, Adopt anhydrous n-hexane to wash the orange-red solid filter residue 3 times, and vacuum-dry to remove the n-hexane in the filter residue to obtain 13.3 g ferrocene lithium salt (Fe(η-C 5 h 4 Li 2 )·2 / 3TMEDA). The dried lithium ferrocene salt was stored in an argon-protected glove box.

Embodiment 1

[0043] (1) Vacuumize the synthesis reaction system, replace high-purity nitrogen to normal pressure, repeat 3 times, take 5 g (18.2 mmol) of ferrocene lithium salt prepared in Reference Example 1 in a 250 mL reaction bottle in the glove box, After sealing, remove it and place it in a -20°C reaction bath, inject 50 mL of anhydrous tetrahydrofuran (THF) with a syringe, and stir to obtain component a; (2) Add 0.94 g (7.3 mmol) of Cl 2 Si(CH 3 ) 2 Dissolve in 30 mL of anhydrous THF, add dropwise to component a obtained in step (1) through a constant pressure dropping funnel, and stir at -20°C for 1 h to obtain component b; (3) add 1.09 g (7.3 mmol) Cl 3 Si CH 3 Dissolve in 30 mL of anhydrous THF, add dropwise to component b obtained in step (2) through a constant pressure dropping funnel, and stir for 12 hours at 25°C to obtain component c; (4) in step (3 ) Add 1 mL of methanol dropwise to the obtained component c to terminate the reaction, filter to obtain 110 mL of filtrate,...

Embodiment 2

[0051] (1) Vacuumize the synthesis reaction system, replace high-purity nitrogen to normal pressure, repeat 3 times, take 5 g (18.2 mmol) of ferrocene lithium salt prepared in Reference Example 1 in a 250 mL reaction bottle in the glove box, After sealing it, remove it and place it in a reaction bath at 25°C; inject 100mL of anhydrous n-hexane with a syringe and stir to obtain component a; (2) add 1.1 g (7.7 mmol) of Cl 2 SiCH 3 CH 2 CH 3 Dissolve in 30 mL of anhydrous n-hexane, add dropwise to component a obtained in step (1) through a constant pressure dropping funnel, stir and react for 3 h at 25°C to obtain component b; (3) add 1.2 g (7.3 mmol) Cl 3 Si CH 2 CH 3 Dissolve in 30 mL of anhydrous n-hexane, add dropwise to component b obtained in step (2) through a constant pressure dropping funnel, stir and react at 30°C for 15 hours to obtain component c; (4) in step ( 3) Add 1 drop of deionized water to the obtained component c to terminate the reaction, filter to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com