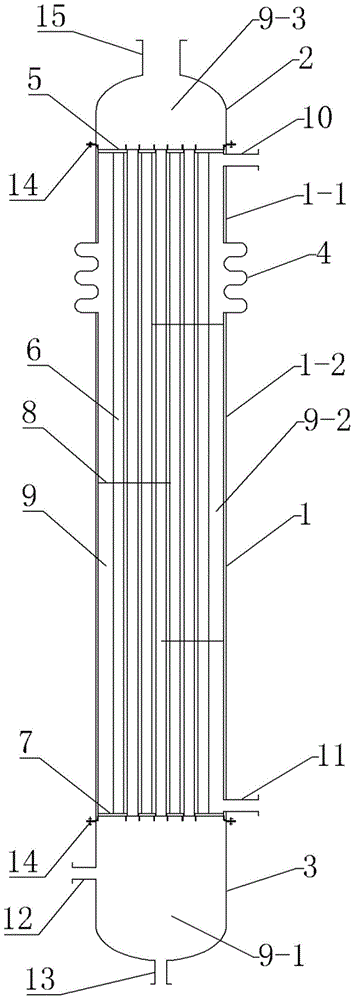

Ceramic material, ceramic heat exchange tube as well as preparation method thereof and ceramic reboiler

A technology of ceramic materials and heat exchange tubes, which is applied in the field of heat exchange equipment, can solve the problems of short service life and high replacement frequency of reboilers, and achieve the effects of avoiding leakage, strong corrosion resistance, and fast heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

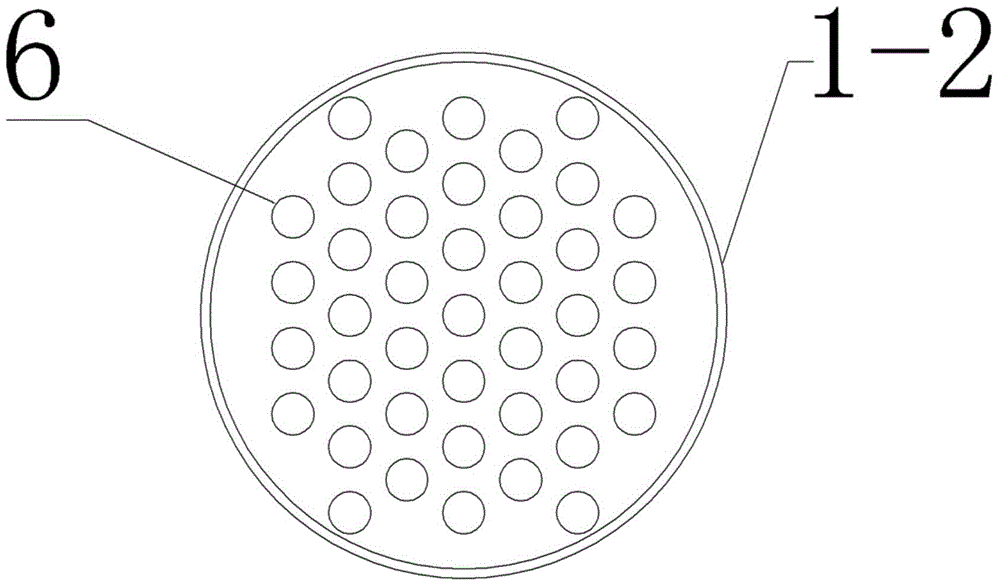

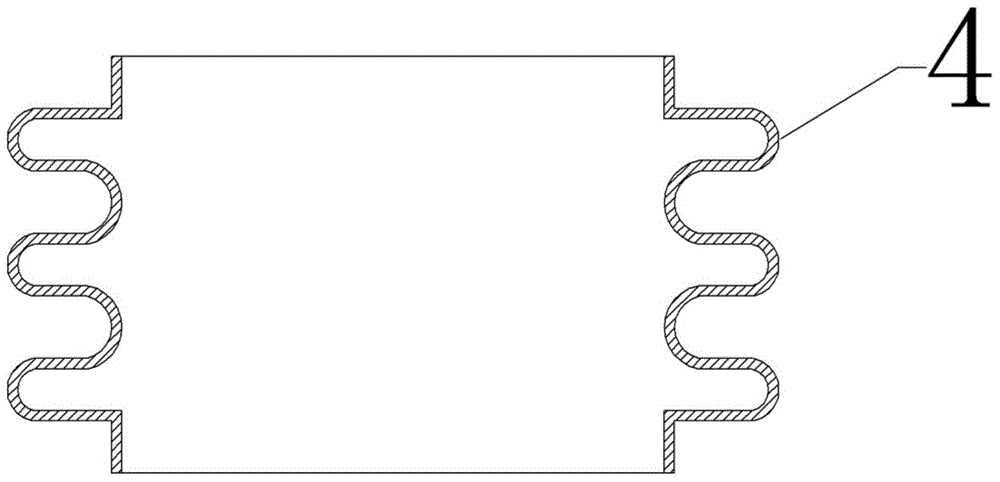

Method used

Image

Examples

Embodiment 1

[0037] The ceramic material in this embodiment is composed of the following components in mass percentage: 5% metallic silicon, 70% silicon carbide, 14% silicon dioxide, 10% bonded clay, and 1% lignin.

[0038] The ceramic heat exchange tube of this embodiment is mainly made of the following raw materials in mass percentage: 5% of metal silicon powder of 800 mesh, 70% of silicon carbide powder of 800 mesh, 14% of silicon dioxide powder of 325 mesh, and 10% of bonded clay of 160 mesh , lignin 1%.

[0039] The preparation method of the ceramic heat exchange tube of this embodiment comprises the following steps:

[0040] 1) Take the metal silicon powder, silicon carbide powder, silicon dioxide powder, and bonded clay in the formula and add them to the ball mill, and add 30% of the total mass of the above powders (metal silicon powder, silicon carbide powder, silicon dioxide powder, and bonded clay) water, mixed and ground for 10 hours to obtain a mixed slurry, which was put into...

Embodiment 2

[0046] The ceramic material in this embodiment is composed of the following components in mass percentage: 8% metallic silicon, 66.8% silicon carbide, 10% silicon dioxide, 15% bonded clay, and 0.2% lignin.

[0047] The ceramic heat exchange tube of this embodiment is mainly made of the following raw materials in mass percentage: 5% of metal silicon powder of 1000 mesh, 70% of silicon carbide powder of 900 mesh, 14% of silicon dioxide powder of 325 mesh, and 10% of bonded clay of 170 mesh , lignin 1%.

[0048] The preparation method of the ceramic heat exchange tube of this embodiment comprises the following steps:

[0049] 1) Take the metal silicon powder, silicon carbide powder, silicon dioxide powder, and bonded clay in the formula and put them into the ball mill, and add 32% of the total mass of the above powders (metal silicon powder, silicon carbide powder, silicon dioxide powder, and bonded clay) water, mixed and ground for 11 hours to obtain a mixed slurry, which was p...

Embodiment 3

[0055] The ceramic material of this embodiment is composed of the following components in mass percentage: 10% of metal silicon, 60% of silicon carbide, 15% of silicon dioxide, 12% of bonded clay, and 0.5% of lignin.

[0056] The ceramic heat exchange tube of this embodiment is mainly made of the following raw materials in mass percentage: 900 mesh metal silicon powder 5%, 1000 mesh silicon carbide powder 70%, 325 mesh silicon dioxide powder 14%, 180 mesh bonded clay 10% , lignin 1%.

[0057] The preparation method of the ceramic heat exchange tube of this embodiment comprises the following steps:

[0058] 1) Take the metal silicon powder, silicon carbide powder, silicon dioxide powder, and bonded clay in the formula and add them to the ball mill, and add 35% of the total mass of the above powders (metal silicon powder, silicon carbide powder, silicon dioxide powder, and bonded clay) water, mixed and ground for 12 hours to obtain a mixed slurry, which was put into the slurry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com