Catalpa tea table and production method thereof

A technology of tea table and catalpa wood, applied in the field of new materials and green manufacturing, can solve the problems of easy mildew, scarcity of resources, cold and slippery color, etc., and achieve the effects of improving fire prevention, simple and easy operation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

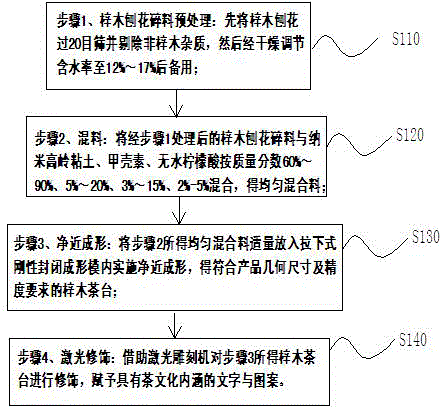

[0024] see figure 1 , a preparation method of catalpa tea table, which comprises the following processing steps:

[0025] Step 1 of S110, pretreatment of catalpa shavings and scraps: first pass the catalpa shavings through a 20-mesh sieve and remove non-catalys impurities, then dry to adjust the moisture content to 12% to 17% for later use; the specific operation of the drying process Dry at 60-90°C for 10-30 minutes.

[0026] Step 2 of S120, mixing: mix the catalpa wood shavings and nano-kaolin clay, chitin, and anhydrous citric acid according to the mass fraction of 60%-90%, 5%-20%, 3%- 15%, 2%-5% mixed to get a uniform mixture.

[0027] Step 3 of S130, net near forming: put an appropriate amount of the homogeneous mixture obtained in step 2 into a pull-down rigid closed forming mold to implement net near forming, and obtain a catalpa tea table that meets the geometric size and precision requirements of the product; the net near The forming process parameters are forming ...

Embodiment 1

[0032] A kind of catalpa tea table, the mass composition of each component is respectively: 9kg of catalpa shavings, 0.5kg of nano kaolin clay, 0.3kg of chitin, 0.2kg of anhydrous citric acid; the particle size of the nano kaolin clay ≤500nm, chitin particle size ≤0.075mm, anhydrous citric acid particle size ≤0.15mm.

[0033] A preparation method of catalpa tea table, comprising the following process steps:

[0034] Step 1. Pretreatment of catalpa wood shavings and scraps: first pass the catalpa wood shavings through a 20-mesh sieve and remove non-catalysia impurities, and then dry at 60°C for 30 minutes to adjust the moisture content to 12% to 17% for later use;

[0035] Step 2, mixing: mix the 9kg catalpa shavings and 0.5kg nano kaolin clay, 0.3kg chitin, and 0.2kg anhydrous citric acid to obtain a uniform mixture after being processed in step 1;

[0036] Step 3, net near-shaping: Put an appropriate amount of the homogeneous mixture obtained in step 2 into a pull-down rigid...

Embodiment 2

[0039] A kind of catalpa tea table, the mass composition of each component is respectively: 6kg of catalpa shavings, 2kg of nano kaolin clay, 1.5kg of chitin, 0.5kg of anhydrous citric acid; the particle size of the nano kaolin clay is ≤ 500nm, the particle size of chitin≤0.075mm, the particle size of anhydrous citric acid≤0.15mm.

[0040] A preparation method of catalpa tea table, comprising the following process steps:

[0041]Step 1. Pretreatment of catalpa wood shavings and scraps: first pass the catalpa wood shavings through a 20-mesh sieve and remove non-catalysia impurities, and then dry them at 90°C for 10 minutes to adjust the moisture content to 12% to 17% for later use;

[0042] Step 2, mixing: mix the 6kg catalpa shavings and 2kg nano kaolin clay, 1.5kg chitin, and 0.5kg anhydrous citric acid to obtain a uniform mixture after being processed in step 1;

[0043] Step 3, net near-shaping: Put an appropriate amount of the homogeneous mixture obtained in step 2 into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com