Internal-expanding type beveling machine

An internal expansion type beveling machine and core technology, which is applied in the direction of expanding mandrels, metal processing mechanical parts, driving devices, etc., can solve the problem of poor groove roughness and dimensional accuracy, difficulty in tensioning, It is easy to damage the blade and other problems, so as to reduce the tool loss and the frequency of tool replacement, take up less processing space and have a simple device structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

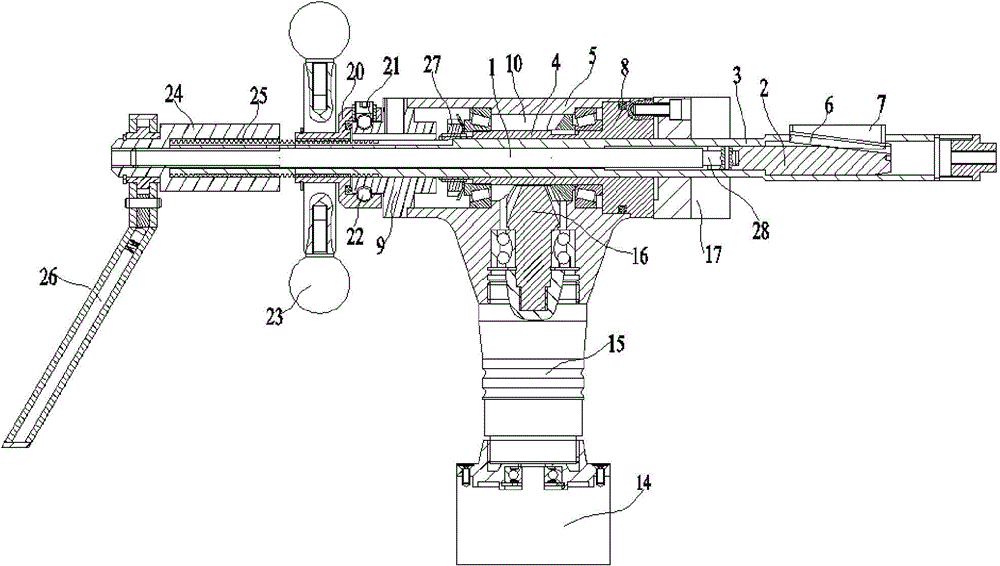

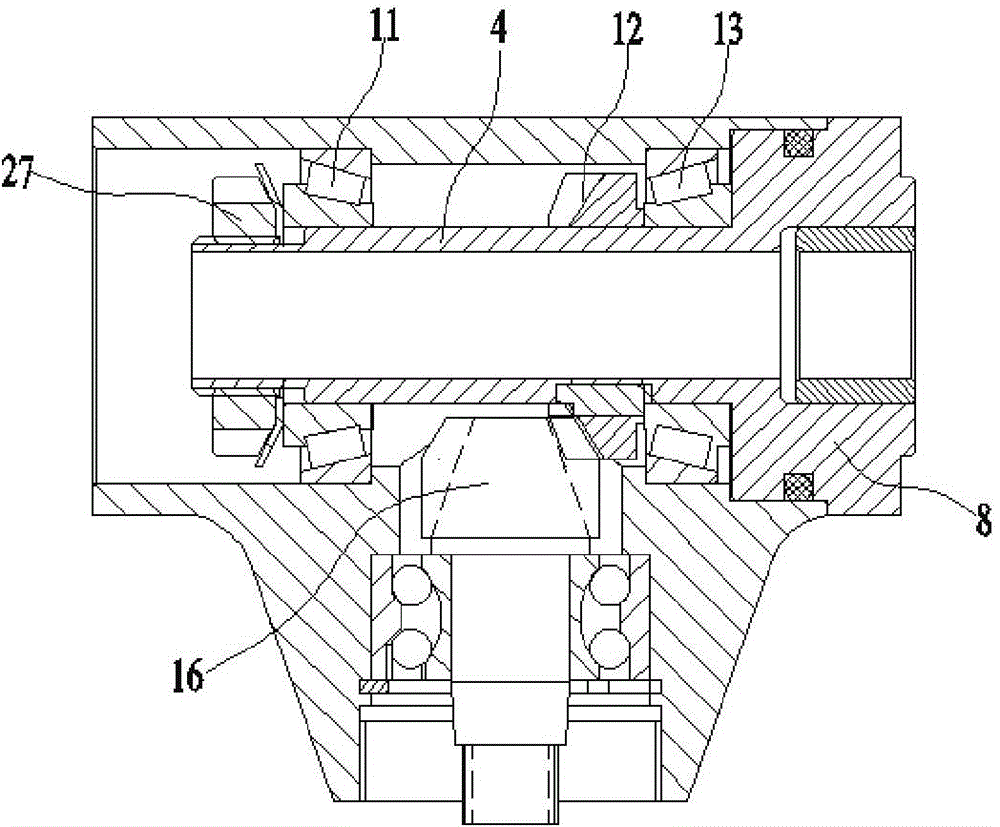

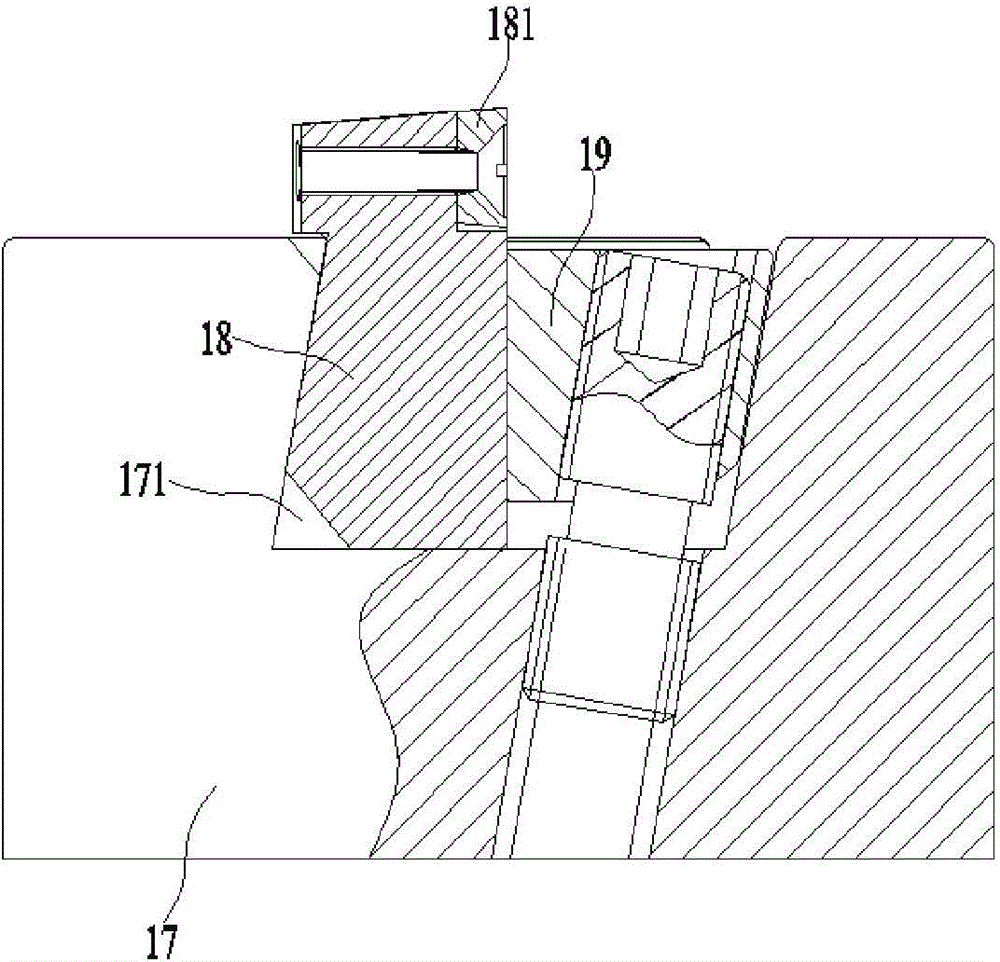

[0022] Embodiment 1: An internal expansion beveling machine, comprising a long inner mandrel 1, a short inner mandrel 2, an outer mandrel sleeve 3, a main shaft sleeve 4 and a housing 5, the long inner mandrel 1, the short inner mandrel The mandrel 2 is embedded in the outer mandrel sleeve 3, the main shaft sleeve 4 is set on the outer surface of the outer mandrel sleeve 3 and is located in the housing 5, the rear outer surface of the outer mandrel sleeve 3 has a trapezoidal thread and wherein, There is a guide groove 31 in the rear part, and at least three oblique guide grooves 6 are provided on the opposite end of the short inner mandrel 2 and the long inner mandrel 1, and an expansion wedge 7 is inserted in the oblique guide groove 6 ;

[0023] The front end of the main shaft sleeve 4 has a cutter base 8, the cutter base 8 is located at the front end of the housing 5, and a rear end cover 9 is mounted on the rear end of the housing 5 to form a cavity 10. A bearing 11, a dr...

Embodiment 2

[0028] Embodiment 2: An internal expansion beveling machine, comprising a long inner mandrel 1, a short inner mandrel 2, an outer mandrel sleeve 3, a main shaft sleeve 4 and a housing 5, the long inner mandrel 1, the short inner mandrel The mandrel 2 is embedded in the outer mandrel sleeve 3, the main shaft sleeve 4 is set on the outer surface of the outer mandrel sleeve 3 and is located in the housing 5, the rear outer surface of the outer mandrel sleeve 3 has a trapezoidal thread and wherein, There is a guide groove 31 in the rear part, and at least three oblique guide grooves 6 are provided on the opposite end of the short inner mandrel 2 and the long inner mandrel 1, and an expansion wedge 7 is inserted in the oblique guide groove 6 ;

[0029] The front end of the main shaft sleeve 4 has a cutter base 8, the cutter base 8 is located at the front end of the housing 5, and a rear end cover 9 is mounted on the rear end of the housing 5 to form a cavity 10. A bearing 11, a dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com