Preparation method of hard alloy pressed blank adapted to general mechanical processing

A cemented carbide and machining technology, which is applied in the field of preparation of cemented carbide green compacts, can solve the problem that cemented carbide formed compacts cannot be processed by conventional machining, etc., so as to reduce subsequent processing costs, improve processing efficiency, and improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Carbide grade: YG6.

[0033] YG6 is a hard alloy composed of 94% metal carbide tungsten carbide and 6% metal binder phase cobalt. The density of tungsten carbide is 15.6 g / cm3, and the density of cobalt is 8.9 g / cm3. The volume content of the junction metal cobalt is: 6÷8.9 / ﹙94÷15.6+6÷8.9﹦10.06﹪.

[0034] The preparation method of compact comprises the following steps:

[0035] a. According to the mass percentage content of 94% tungsten carbide and 6% cobalt, the YG6 cemented carbide mixture is prepared, and the green compact is made by isostatic pressing.

[0036] b. Put the formed compact into a vacuum sintering furnace for pre-sintering. Since the volume content of the binder phase metal cobalt is 10.06%, the sintering temperature is set at 875°C, and the holding time is 80 minutes. After the pre-sintering is completed, cool down to room temperature, the cemented carbide compact of the present invention is obtained.

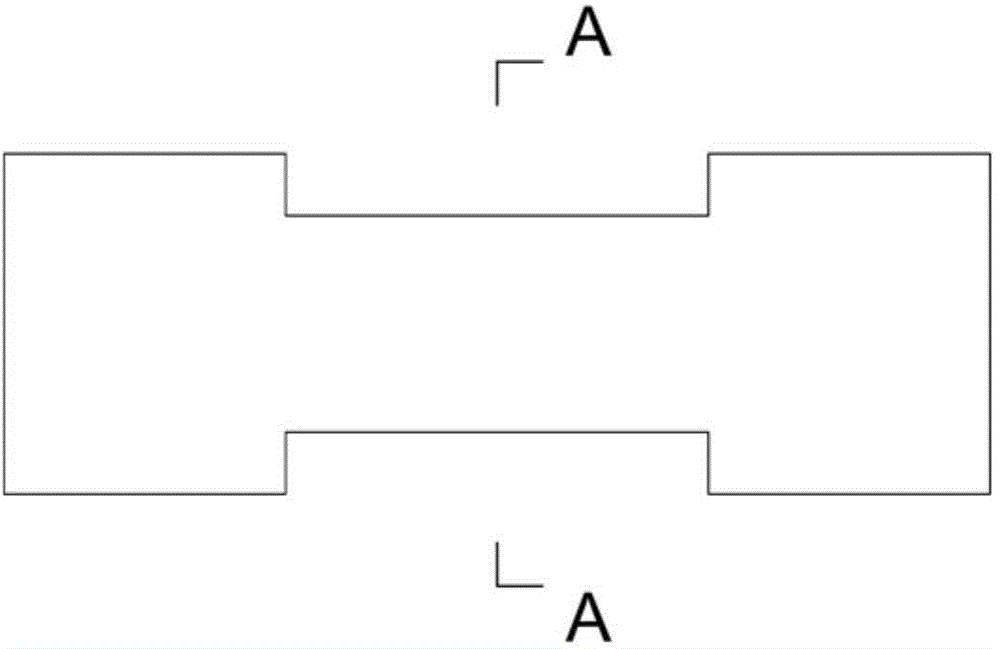

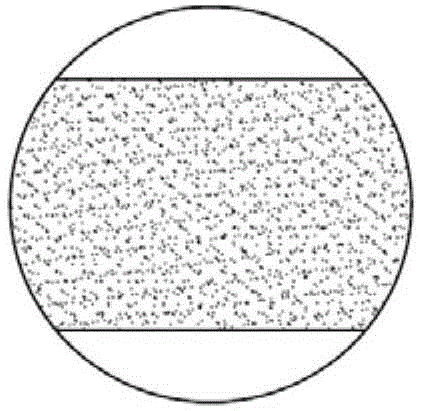

[0037] refer to Picture 1-1 , 1-2, 1-3, choos...

Embodiment 2

[0046] Carbide grade: YN10.

[0047] YN10 is a hard alloy composed of 90% metal carbide tungsten carbide and 10% metal binder phase nickel. The density of tungsten carbide is 15.6 g / cm3, and the density of nickel is 8.9 g / cm3. The volume content of the junction metal nickel is: 10÷8.9 / ﹙90÷15.6+10÷8.9﹦16.30﹪.

[0048] The preparation method of compact comprises the following steps:

[0049]a. Prepare the YN10 cemented carbide mixture according to the mass percentage content of 90% tungsten carbide and 10% nickel, and make a green compact by isostatic pressing.

[0050] b. Put the formed compact into a vacuum sintering furnace for pre-sintering. Since the volume content of nickel in the binder phase is 16.30%, the sintering temperature is set at 865°C and the holding time is 75 minutes. Cool down after pre-sintering to room temperature, the cemented carbide compact of the present invention is obtained.

[0051] refer to figure 2 , choose artificial diamond tools, and machin...

Embodiment 3

[0059] Carbide grade: YG23C.

[0060] YG23C is a hard alloy composed of 77% metal carbide tungsten carbide and 23% metal binder phase cobalt. The density of tungsten carbide is 15.6 g / cm3, and the density of cobalt is 8.9 g / cm3. The volume content of the junction metal cobalt is: 23÷8.9 / ﹙77÷15.6+23÷8.9﹦34.37﹪.

[0061] The preparation method of compact comprises the following steps:

[0062] a. Prepare the YG23C cemented carbide mixture according to the mass percentage content of 77% tungsten carbide and 23% cobalt, and make a compact by molding and pressing.

[0063] b. Put the formed compact into a vacuum sintering furnace for pre-sintering. Since the volume content of the binder phase metal cobalt is 34.37%, the sintering temperature is set at 815°C, and the holding time is 60 minutes. After the pre-sintering is completed, cool down to room temperature, the cemented carbide compact of the present invention is obtained.

[0064] refer to Figure 3-1 , 3-2, select artific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com