Preparation method of carbon nano-tube and graphene-based oil absorption foam material

A carbon nanotube and foam material technology is applied in the field of preparation, which can solve the problems of low reuse rate and easy falling off of the adsorption layer, and achieve the effects of high oil absorption rate, improved mechanical strength, and easy mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

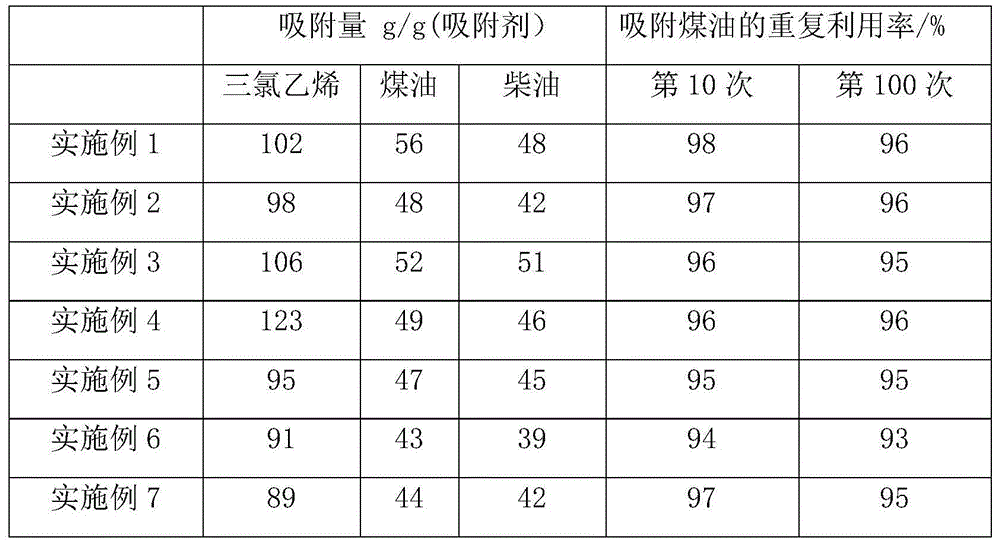

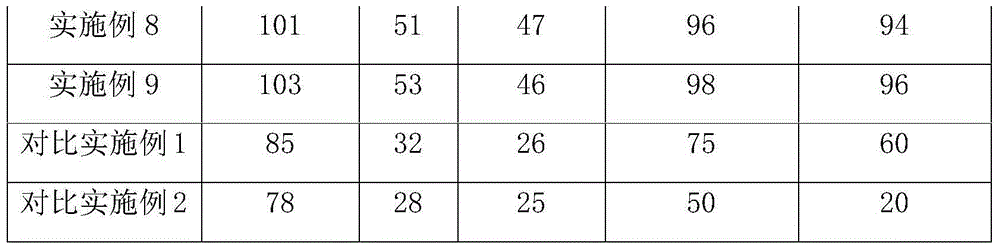

Embodiment 1

[0022] Mix strong oxidant 98% concentrated sulfuric acid, graphene oxide, and carbon nanotubes at a mass ratio of 100:1:0.1, ultrasonically perform deep oxidation for 10 minutes, and then filter and wash to neutral to form a concentration of 0.1mg / mL water dispersion. Submerge a polyurethane porous sponge cube with a side length of 5 cm in 62.5 mL of graphene oxide / carbon nanotube dispersion for 0.5 min, take it out and irradiate it with a 500W microwave for 30 min, then place it in a vacuum oven at 40 °C Dry until completely dry, and treat the dried carbon nanotube / graphene oxide foam material in a tube furnace at a temperature of 100°C for 10 hours to obtain a carbon nanotube / graphene-based oil-absorbing foam material. Table 1.

Embodiment 2

[0024] Mix 70% concentrated nitric acid, graphene oxide, and carbon nanotubes at a mass ratio of 200:1:0.01 as a strong oxidizing agent, and perform deep oxidation by ultrasonication for 50 minutes. Dispersions. Submerge a cube of polyurethane porous sponge with a side length of 5 cm in 125 mL of graphene oxide / carbon nanotube dispersion for 2 min, take it out and irradiate it with a microwave of 700 W for 20 min, then place it in a vacuum oven and dry it at 60 °C Until it was completely dry, the dried carbon nanotube / graphene oxide foam material was treated in a tube furnace at a temperature of 200°C for 5 hours to obtain a carbon nanotube / graphene-based oil-absorbing foam material, and its oil-absorbing performance was tested in Table 1.

Embodiment 3

[0026] Mix 30% hydrogen peroxide, graphene oxide, and carbon nanotubes at a mass ratio of 300:1:0.2 as a strong oxidizing agent, and perform deep oxidation by ultrasonication for 100 minutes. liquid. Submerge a polyurethane porous sponge cube with a side length of 5 cm in 250 mL of graphene oxide / carbon nanotube dispersion for 30 min, take it out and irradiate it with 1000 W microwave for 1 min, then place it in a vacuum oven and dry it at 40 °C Until it is completely dry, the dried carbon nanotube / graphene oxide foam material is treated in a tube furnace at a temperature of 350°C for 0.5h to obtain a carbon nanotube / graphene-based oil-absorbing foam material, and its oil-absorbing performance is shown in the table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com