Preparation method of plant-derived colored antibacterial viscose fiber

A viscose fiber, plant-derived technology, applied in the preparation of spinning solution, man-made filament made of viscose, wet spinning, etc. High temperature and other problems, to achieve the effect of reducing energy loss, lasting dyeing effect, and overcoming low color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

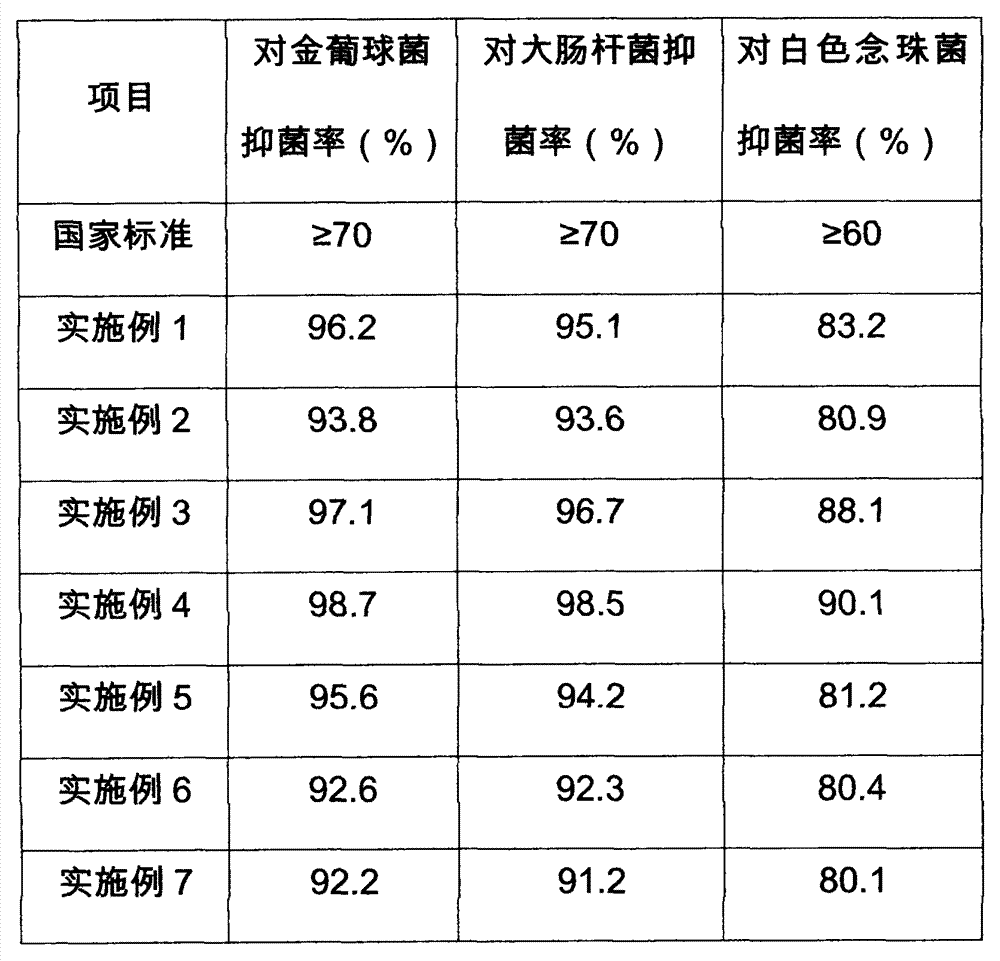

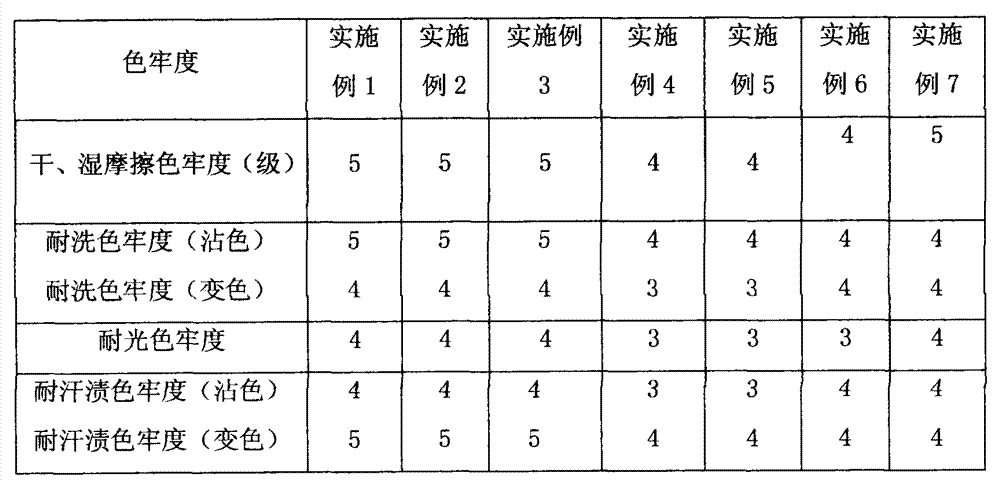

Examples

Embodiment 1

[0024] Embodiment 1 A kind of plant source colored antibacterial viscose fiber

[0025] (1) Configuration of antibacterial dye solution: Gentiana and Millennium Extract powder are mixed evenly by mass ratio = 50%: 50%, and then added to the dissolution kettle, soft water is added, and the mass ratio is 1: 5; defoaming is added Stabilizer organic siloxane, the quality is 0.08% of the antibacterial dye extract powder, the temperature is controlled at 55 ° C, the rotating speed is 180 rpm, stirred for 70 minutes, cooled to room temperature, and filtered after standing for 2.5 hours to obtain 18wt% antibacterial Dye solution.

[0026] (2) Configuration of dyeing mordant solution: mix persimmon skin and loquat leaf extract powder evenly by mass ratio = 80%: 20%, add in the dissolving kettle, add soft water, the mass ratio is 1: 15, add dispersion stabilizer 5040, the quality is 0.4% of the dyeing mordant extract powder, the temperature is controlled at 51° C., the rotating speed i...

Embodiment 2

[0030] Embodiment 2 A kind of plant source colored antibacterial viscose fiber

[0031] (1) Configuration of antibacterial dye solution: Gentiana and Millennium Extract powder are mixed evenly by mass ratio = 20%: 80%, and then added to the dissolving kettle, soft water is added, and the mass ratio is 1: 7; defoaming is added Stabilizer organic siloxane, the quality is 0.01% of the antibacterial dye extract powder, the temperature is controlled at 50°C, the rotating speed is 190 rpm, stirred for 60min, cooled to room temperature, filtered after standing for 2 hours, and 14wt% antibacterial Dye solution.

[0032] (2) Configuration of dyeing mordant solution: mix persimmon skin and loquat leaf extract powder evenly by mass ratio = 50%: 50%, add in the dissolving kettle, add soft water, the mass ratio is 1: 12, add dispersion stabilizer 5040, the quality is 0.6% of the dyeing mordant extract powder, the temperature is controlled at 53° C., the speed is 120 rpm, stirred for 50 mi...

Embodiment 3

[0036] Embodiment 3 A kind of plant source colored antibacterial viscose fiber

[0037] (1) Configuration of antibacterial dye solution: Gentiana and Millennium Extract powder are mixed evenly by mass ratio=60%: 40%, and then added to the dissolving kettle, soft water is added, and the mass ratio is 1:4; add defoaming Stabilizer organosiloxane, the quality is 0.05% of the antibacterial dye extract powder, the temperature is controlled at 56 ° C, the rotating speed is 180 rpm, stirred for 80 min, cooled to room temperature, filtered after standing for 2 hours, and 20.0 wt % of Antibacterial stain solution.

[0038] (2) Configuration of dyeing mordant solution: mix persimmon skin and loquat leaf extract powder evenly by mass ratio = 80%: 20%, add in the dissolving kettle, add soft water, the mass ratio is 1: 18, add dispersion stabilizer 5040, the quality is 0.4% of the dyeing mordant extract powder, the temperature is controlled at 50° C., the speed is 110 rpm, stirred for 45 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry breaking strength | aaaaa | aaaaa |

| Wet breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com