Iron ore sintering method with ultrahigh-proportion flue gas circulation

A flue gas circulation and sintering method technology, which is applied in the field of iron and steel metallurgy, can solve the problems of incomplete combustion of fuel, increase the sulfur load of blast furnace ironmaking, reduce sintering production efficiency and sinter quality, and achieve consistency and reduce flue gas The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

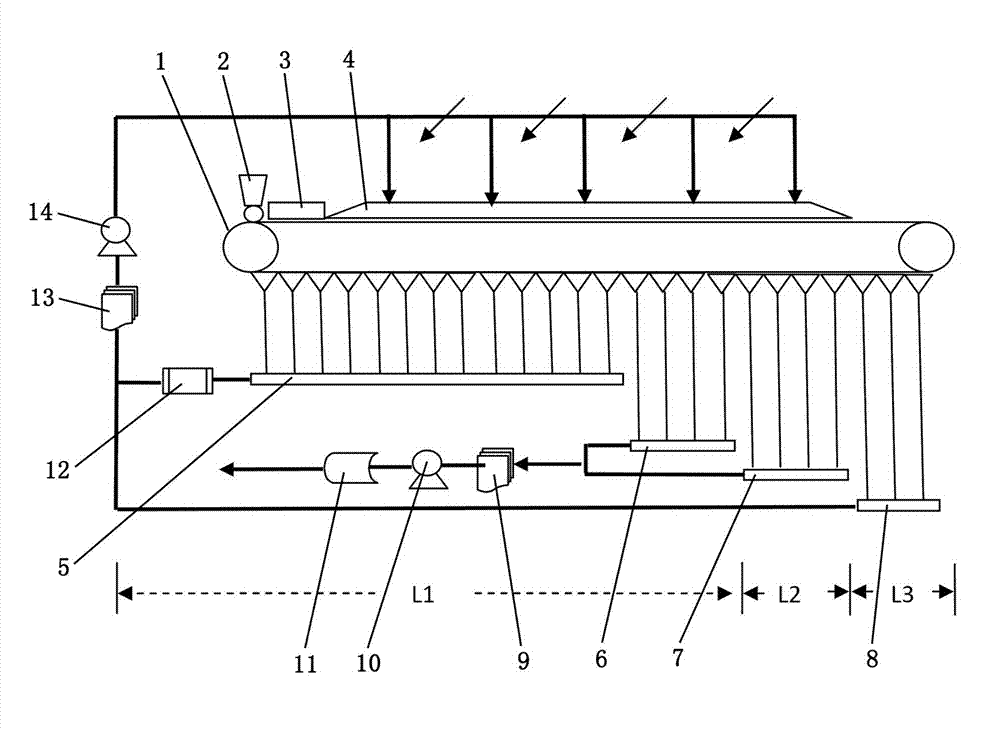

[0023] Raw material conditions for sintering: batching according to the mass ratio of mixed iron ore 61.22%, dolomite 5.01%, limestone 2.33%, quicklime 4.51%, sintering return ore 23.08%, coke powder 3.85% (the main chemical composition of the obtained sinter is: TFe57. 7%, SiO24.9%, R2.0, MgO1.8%). The above-mentioned sintering raw materials are distributed into the sintering machine 1 through the distributing device 2 for sintering.

[0024] The head flue gas of sintering machine 1 accounts for 50% of the total volume of sintering flue gas, the middle flue gas accounts for 30% of the total volume of sintering flue gas, the tail flue gas accounts for 20% of the total volume of sintering flue gas, and the fume cover 4 covers the sintering machine 1 has an area of 80%. 60% of the head flue gas is intercepted through the head circulation flue 5 for circulation, and the head flue gas is condensed and dehydrated by the condensing device 12 until the volume concentration of wate...

Embodiment 2

[0026]Raw material conditions for sintering: batching according to the mass ratio of mixed iron ore 61.41%, dolomite 5.61%, limestone 2.05%, quicklime 3.85%, sintering return ore 23.08%, coke powder 4.00% (the main chemical composition of the obtained sinter is: TFe58. 33%, SiO25.0%, R1.9, MgO2.3%). The above-mentioned sintering raw materials are distributed into the sintering machine 1 through the distributing device 2 for sintering.

[0027] The head flue gas of sintering machine 1 accounts for 55% of the total volume of sintering flue gas, the middle flue gas accounts for 20% of the total volume of sintering flue gas, the tail flue gas accounts for 25% of the total volume of sintering flue gas, and the fume cover 4 covers the sintering machine 1 has an area of 75%. 80% of the head flue gas is intercepted through the head circulation flue 5 for circulation, and the head flue gas is condensed and dehydrated by the condensing device 12 until the volume concentration of wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com