A system and method for reducing gas purification and tail gas treatment in a gas-based shaft furnace system

A technology of tail gas treatment and gas-based shaft furnace, which is applied in the direction of chemical instruments and methods, separation methods, granular/powdered fuel gasification, etc., to achieve the effects of ensuring continuity, reducing consumption, and avoiding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

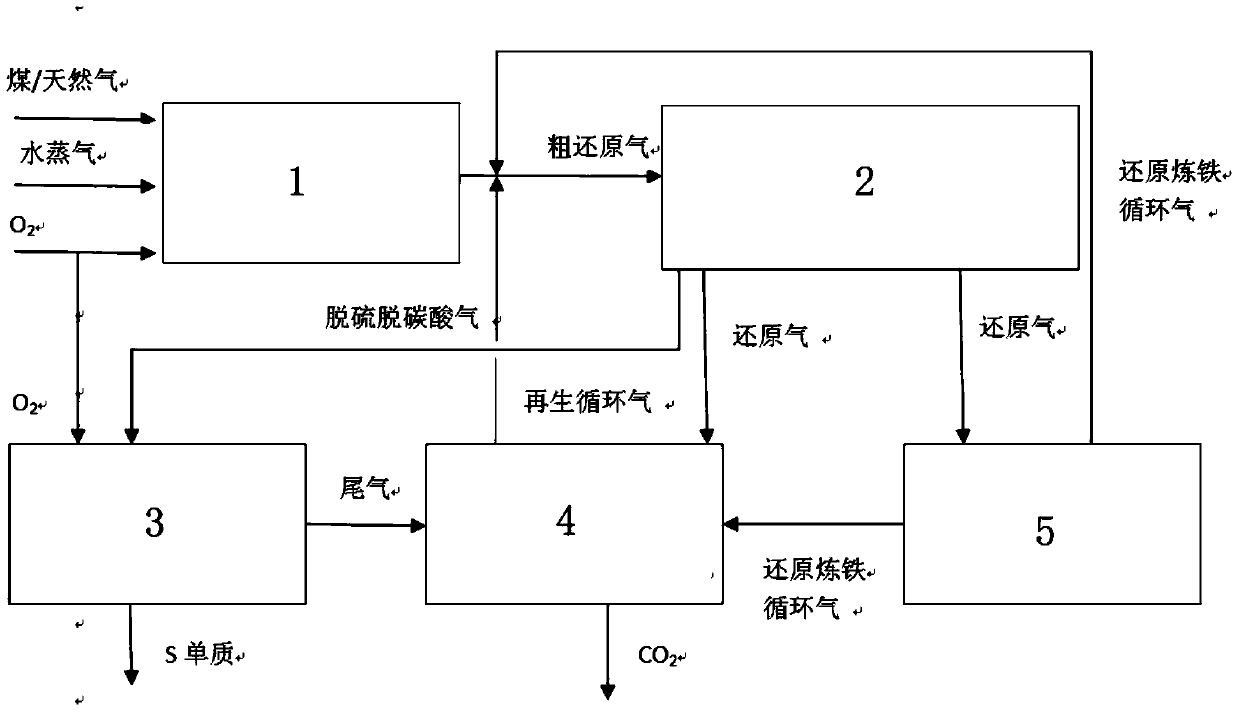

[0033] In this embodiment, pulverized coal pyrolysis method is used to use oxygen, pulverized coal, and water vapor as raw materials. As shown in the figure, the specific process steps include:

[0034] (1) Preparation of crude reducing gas

[0035] The raw materials are prepared in the crude reducing gas preparation unit 1 at a temperature of 1000° C. and a reaction pressure of 0.8 MPa. The hydrocarbon ratio of the product gas is adjusted by adjusting the amount of water vapor introduced at 200° C. The main components of the crude reducing gas produced by this unit include CO 2 , CO, H 2 O, H 2 And H 2 S, where CO 2 The content is 3%, and the hydrogen sulfide content is 5g / m 3 .

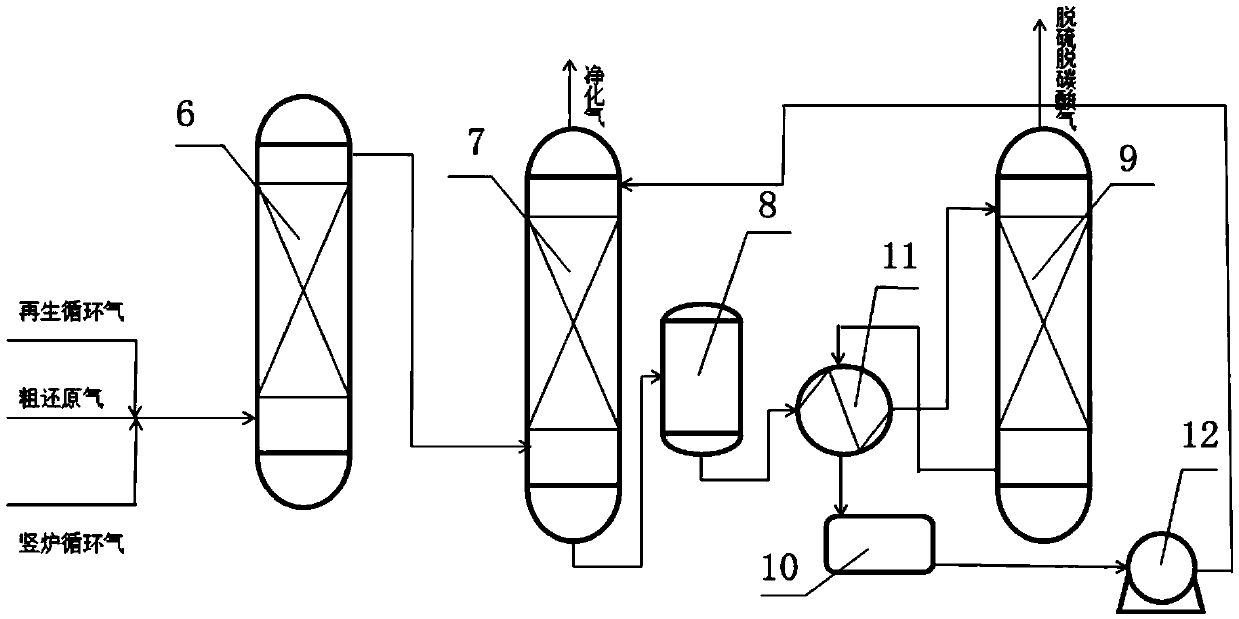

[0036] (2) Crude reducing gas purification

[0037] The crude reduction gas from the crude reduction gas preparation unit 1 enters the crude reduction gas desulfurization and decarbonization unit 2. First, it enters the crude reducing gas washing tower 6. The gas comes into countercurrent contact with the ...

Embodiment 2

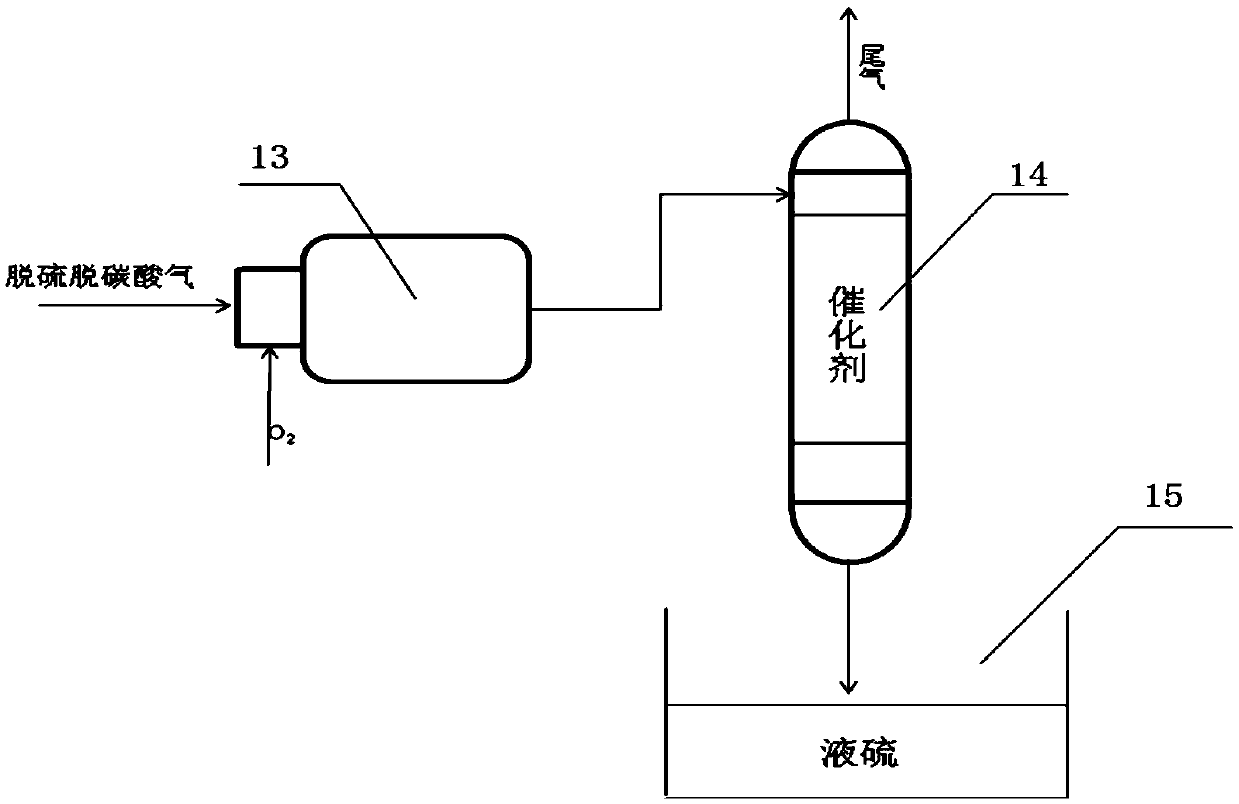

[0050] Using the method of partial oxidation of natural gas, natural gas (hydrogen sulfide content is 20g / m 3 ), steam and oxygen are used to prepare crude reducing gas in crude reducing gas preparation unit 1, wherein the hydrogen sulfide content in natural gas is 20g / m 3 The reaction temperature is 900°C, the reaction pressure is 0.8MPa, and the hydrocarbon ratio of the product gas is adjusted by adjusting the amount of water vapor at 200°C. The main components of the crude reducing gas produced by this unit include CO 2 , CO, H 2 O, H 2 , H 2 S and SO 2 , Where CO 2 5%, hydrogen sulfide content is 8g / m 3 , The sulfur dioxide is 100ppm, and the operating conditions are the same as in Example 1. The tail gas composition after the tail gas treatment and the catalyst regeneration unit 4 is: CO 2 Content 99.9%, SO 2 Not detected, H 2 S is not detected.

[0051] Compared with the prior art, the present invention has the following advantages and advancements:

[0052] (1) For the reduci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com