Method for determining cadmium and trace lead in iron ore

An iron ore and micro-quantity technology, applied in the field of physical and chemical testing, can solve the problems of expensive ICP-MS method, difficulty in popularizing testing companies, and insufficient sensitivity to meet the requirements, and achieve rapid sample decomposition, low loss, and low reagent consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1.1 Main Instruments

[0023] AA240Z graphite furnace atomic absorption spectrometer (Varian, USA); PSD120 graphite furnace autosampler (Varian, USA); O2E-05 cadmium hollow cathode lamp; WB24A lead hollow cathode lamp. ETHOS A microwave digestion instrument (LabTech, USA), equipped with 12 100mL high-pressure digestion tanks. Milli-Q Advantage A10 ultrapure water system (Millipore, USA): resistivity 18.2MΩ·cm.

[0024] 1.2 Main reagents

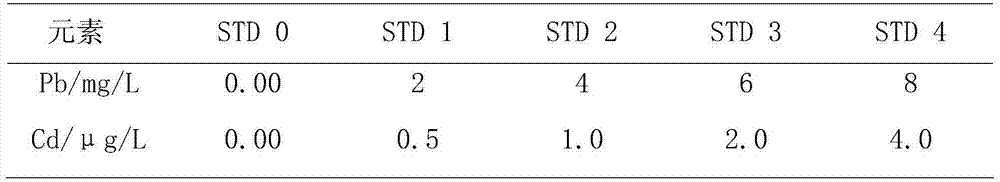

[0025] Lead and cadmium standard stock solutions (National Iron and Steel Materials Testing Center): Both are 1000 μg / mL, diluted into standard working solutions of different concentrations as required (see Table 1).

[0026] Table 1 Concentrations of Pb and Cd in standard working solutions

[0027]

[0028] 1.3 Experimental method

[0029] Weigh 0.5g iron ore sample dried at 105°C, place it in a 100mL polytetrafluoroethylene digestion tank, moisten it with a small amount of deionized water, add 10mL aqua regia, and wait for the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com