Compound circulating fluidized bed gasification reaction device

A technology of circulating fluidized bed and gasification reaction, which is applied in the direction of gasification device feeding tools, gasification process, granular/powdered fuel gasification, etc. Oxygen consumption of slag greatly increases operating costs, and there is no reliable technology for long-term stable operation, etc., to achieve the effects of easy large-scale expansion, accelerated gas-solid two-phase heat and mass transfer, and simplified ash and slag treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

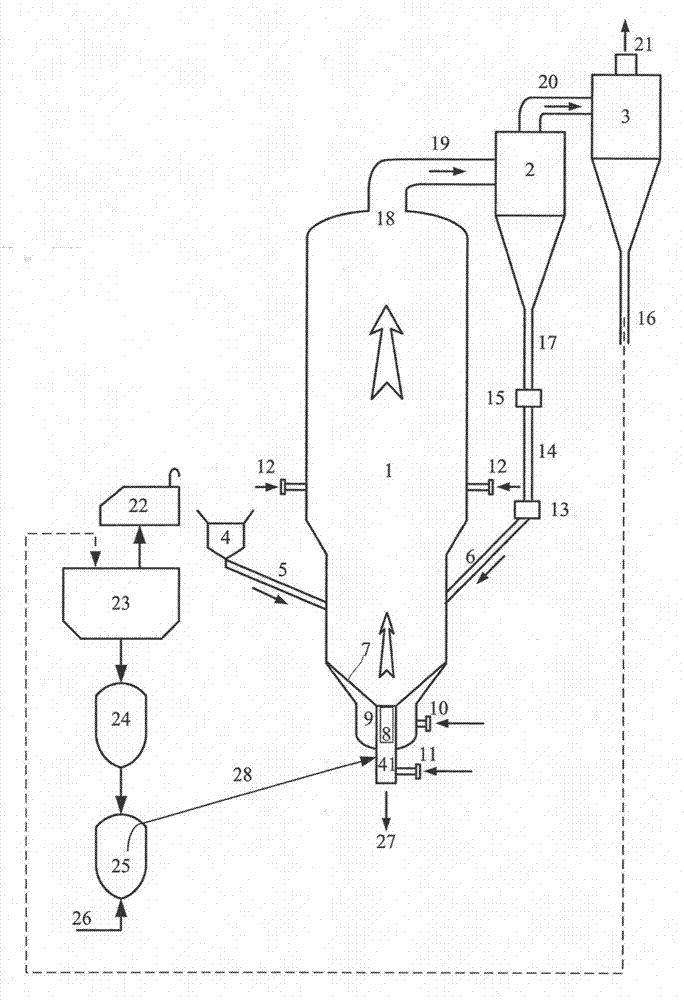

[0033] figure 1It is a schematic diagram of the composite circulating fluidized bed gasification reaction device provided by the present invention. The composite circulating fluidized bed gasification reaction device consists of a reactor body, a multi-stage cyclone separator, a particle fuel feeding system, a powder fuel It is composed of feeding system, center jet gasification burner and feeding system.

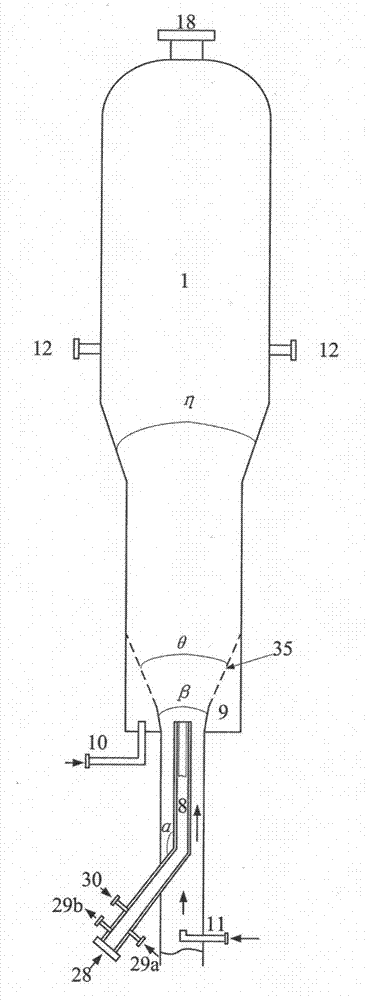

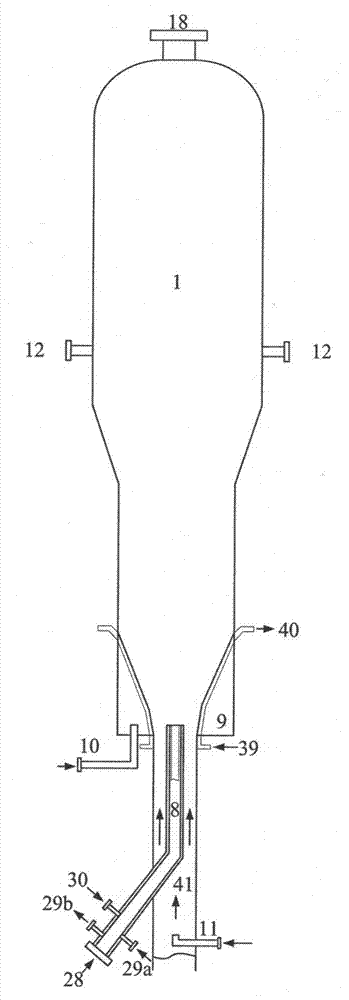

[0034] The reactor body is composed of gasifier body 1, reactor outlet 18, air distribution plate 7, gasification agent distribution chamber 9, second-stage gasification burner chamber 12, central slag discharge pipe 41 and other main components. The reactor outlet 18 is set on the top of the gasifier body 1, the bottom of the gasifier body 1 is provided with an air distribution plate 7 and a central slag discharge pipe 41, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com