Ardealite modified and strengthened damp-proof gypsum block

A gypsum block, phosphogypsum technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of poor sound insulation, waterproof and fireproof effect, insufficient strength, etc., and achieve increased strength , the effect of reducing pollution and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1. Phosphogypsum modified reinforced moisture-proof gypsum block, which is made of the following raw materials in proportion by weight;

[0032] 80 parts of hemihydrate gypsum;

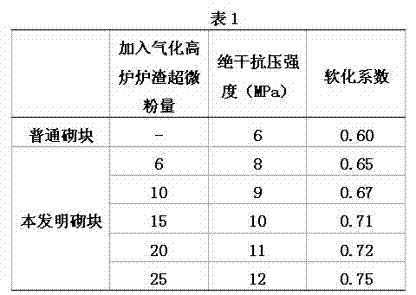

[0033] 15 parts of superfine powder of gasified blast furnace slag;

[0034] 2 parts of activator;

[0035] 70 parts of water.

[0036] The activator is calcium oxide.

[0037] The hemihydrate gypsum is α-type hemihydrate gypsum.

[0038] The gasification blast furnace slag ultrafine powder is obtained by grinding the vitreous slag into ultrafine powder from the vitreous slag remaining in the gasification blast furnace produced by synthetic ammonia. The gasification blast furnace is a gasification blast furnace for producing ammonia.

Embodiment 2

[0039] Example 2. Phosphogypsum modified reinforced moisture-proof gypsum block, which is made of the following raw materials in proportion by weight;

[0040] 80 parts of hemihydrate gypsum;

[0041] 15 parts of superfine powder of gasified blast furnace slag;

[0042] 2 parts of activator;

[0043] 70 parts of water;

[0044] Fiber 3 servings.

[0045] The activator is calcium oxide.

[0046] The hemihydrate gypsum is α-type hemihydrate gypsum.

[0047] The fibers are glass fibers.

[0048] The gasification blast furnace slag ultrafine powder is obtained by grinding the vitreous slag into ultrafine powder from the vitreous slag remaining in the gasification blast furnace produced by synthetic ammonia. The gasification blast furnace is a gasification blast furnace for producing ammonia.

Embodiment 3

[0049] Example 3. Phosphogypsum modified reinforced moisture-proof gypsum block, which is made of the following raw materials in proportion by weight;

[0050] 40 parts of hemihydrate gypsum;

[0051] 6 parts of superfine powder of gasified blast furnace slag;

[0052] 0.5 parts of activator;

[0053] 20 parts of water.

[0054] The activator is calcium hydroxide.

[0055] The hemihydrate gypsum is β-type hemihydrate gypsum.

[0056] The gasification blast furnace slag ultrafine powder is obtained by grinding the vitreous slag into ultrafine powder from the vitreous slag remaining in the gasification blast furnace produced by synthetic ammonia. The gasification blast furnace is a gasification blast furnace for producing ammonia.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com