Preparation method of residual oil hydrogenation monolithic catalyst

A monolithic catalyst and residual oil hydrogenation technology, which is applied in the chemical industry, can solve the problems of macromolecular colloids and asphaltene micelles passing through the pores, diffusion resistance and high reaction pressure, etc., to shorten the downtime period and load the amount of active metals The effect of high and high hydrogenation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

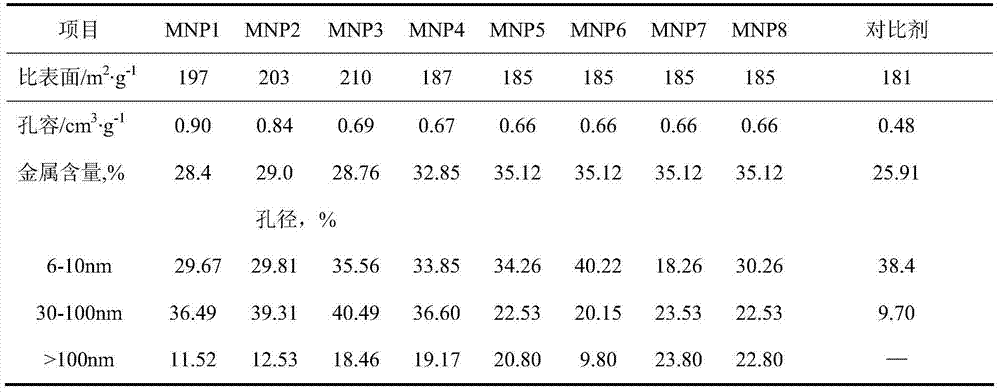

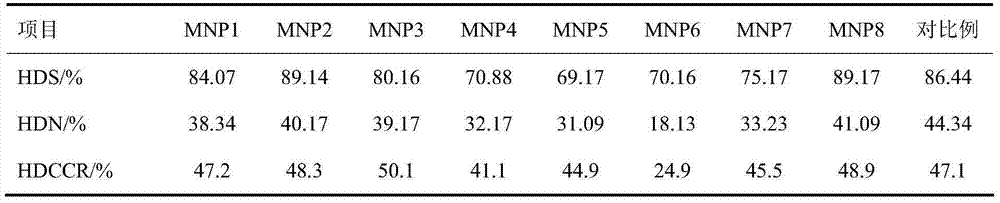

Embodiment 1

[0017] ①Mix 10g of SB powder and alumina powder evenly according to the mass ratio of 1:6, divide it into 5 parts evenly, and put 0.2g of crushed superfine fiber in the mold alternately and evenly, and the fiber is crushed into 0.5-1.5mm length Polyester fiber, the monofilament linear density of polyester fiber is 0.1-0.6dtex, each layer is evenly sprayed with a concentration of 6mol L -1 dilute nitric acid, shared 2g, and calcined at 550°C for 12h after tableting to obtain the carrier of the monolithic catalyst;

[0018] ② Immerse the prepared carrier with 30% Tween-80 aqueous solution for 1 hour, filter off excess solution, and dry the impregnated carrier at 110° C. for 4 hours. Using the method of multiple saturation impregnation in the solution containing 1.5mol·L -1 Molybdenum and 0.43mol L -1 Nickel is immersed in the molybdenum-nickel-phosphorus solution prepared with a mass ratio of 4:1 for 1h, and the oxide (MoO 3 +NiO) contains 30% by weight, and the content is ba...

Embodiment 2

[0021] Same as in Example 1, except that the amount of polyester fiber is 0.3 g, and the amount of dilute nitric acid is 3 g, to obtain a monolithic catalyst carrier. The mass concentration of Tween-80 used is 40% aqueous solution for immersion for 1 h, excess solution is filtered off, and the impregnated carrier is dried at 110° C. for 4 h. Use 1.5mol·L -1 Molybdenum and 0.43mol L -1 The molybdenum-nickel-phosphorus solution prepared by nickel at a mass ratio of 5:1 was impregnated with the carrier for 1 h, and the oxide (MoO 3 +NiO) containing 30% by weight, dried in a fume hood, then dried at 110°C for 6h, and then calcined at 550°C for 12h to obtain catalyst MNP2.

Embodiment 3

[0023] Same as Example 1, except that the amount of polyester fiber is 0.5 g, and the amount of dilute nitric acid is 3 g, so as to obtain the monolithic catalyst carrier. The mass concentration of Tween-80 used is 50% aqueous solution for 1 h immersion, excess solution is filtered off, and the impregnated carrier is dried at 110° C. for 4 h. Use 1.5mol·L -1 Molybdenum and 0.43mol L -1 The nickel was impregnated in the molybdenum-nickel-phosphorus solution prepared with a mass ratio of 6:1. After the carrier was impregnated for 1 h, the oxide (MoO 3 +NiO) containing 30% by weight, dried in a fume hood, then dried at 110°C for 6h, and then calcined at 600°C for 12h to obtain catalyst MNP3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com