Method for forming graphene interconnecting wire

A technology of interconnect wires and graphene, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of easy damage of graphene films, avoid process risks, avoid transfer processes, and solve easy damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

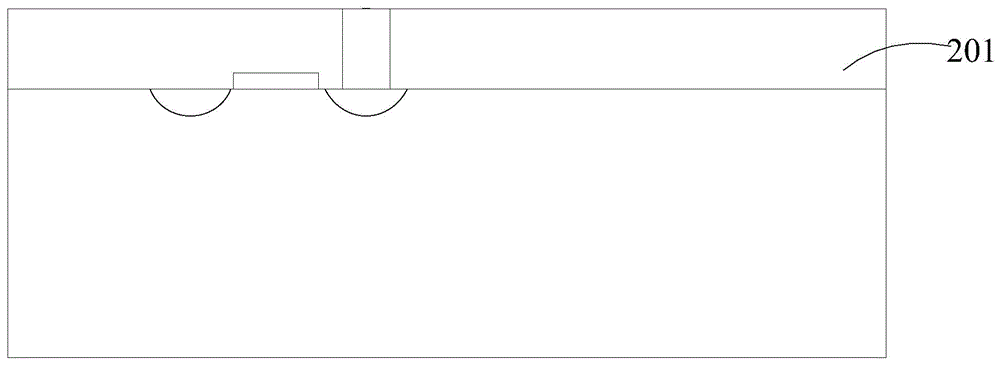

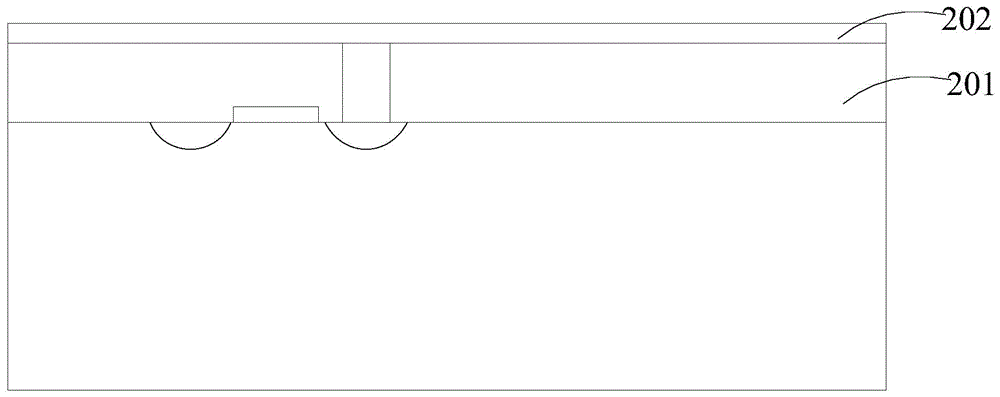

[0031] see figure 1 , figure 1 It is a schematic flow diagram of a preferred embodiment of a method for forming graphene interconnection provided by the present invention; at the same time, please refer to Figure 2a-2f , Figure 2a-2f It is a structural schematic diagram of a preferred embodiment for forming graphene interconnection provided by the present invention.

[0032] The present invention provides a method for forming graphene interconnection lines, comprising steps S01 to S06, specifically as follows:

[0033] Such as Figure 2a As shown, step S01: provide a target substrate 201; in this embodiment, the target substrate 201 has completed the preparation of transistor front-end process and via interconnection, and the target substrate 201 includes transistors fabricated on the substrate Included device layers and copper interconnect structures.

[0034] Such as Figure 2b As shown, step S02: forming a uniform and thickness-controllable carbon source layer 202 o...

Embodiment 2

[0040] In the second embodiment, a method for forming a metal / graphene hybrid interconnection line will be introduced. Please refer to Figure 3a-3f , Figure 3a-3f It is a structural schematic diagram of a preferred embodiment of a method for forming a metal / graphene hybrid interconnection provided by the present invention.

[0041] Different from Embodiment 1, in this embodiment, steps S03 and S05 in Embodiment 1 can be selectively skipped in the method for forming graphene interconnection lines, only steps S01, S02, S04 and S06, specifically Include the following steps:

[0042] Such as Figure 3a As shown in -c, step S01: provide a target substrate 301; specifically, the target substrate 301 has completed the preparation of transistor front-end process and via interconnection, and the target substrate includes transistors fabricated on the substrate. internal device layers and copper interconnect structures. In this embodiment, an intermetallic dielectric layer 302 can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| carrier mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com