Copper/cerium-containing antimicrobial stainless steel and preparation method thereof

An antibacterial stainless steel and stainless steel technology, applied in the field of stainless steel and its preparation, antibacterial stainless steel and its preparation, can solve the problem that the antibacterial effect needs to be further improved, and achieve the effect of large utilization value, improved corrosion resistance and dense steel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

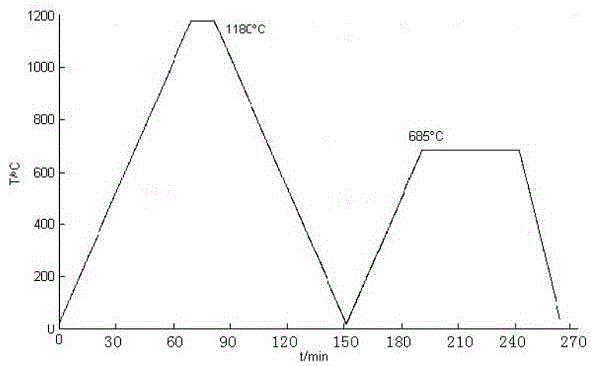

[0020] In this example, see figure 1 , a preparation method of antibacterial stainless steel containing copper and cerium, comprising the following steps:

[0021] a. Smelting to prepare stainless steel primary billet: First, put the alloying element raw materials weighed according to the formula into the crucible in the induction furnace, fully stir and mix, and heat the alloying element raw materials to 1500 ℃ in the induction furnace and maintain a constant temperature until the sample It is completely melted in the crucible, smelted, and then water-cooled to room temperature to prepare the stainless steel initial billet. : 0.030%, Cr: 17.5%, Ni: 11%, Cu: 0.5%, Ce: 0.01%, the balance is Fe and inevitable impurities;

[0022] b. Solid solution strengthening of stainless steel billet: After smelting and preparing stainless steel preliminary billet, heat the stainless steel preliminary billet to 1180℃ in an induction furnace for solution treatment. The solution treatment time...

Embodiment 2

[0026] This embodiment is basically the same as the first embodiment, and the special features are:

[0027] In this embodiment, a method for preparing an antibacterial stainless steel containing copper and cerium includes the following steps:

[0028] a. Smelting to prepare stainless steel initial billet: Weigh 304 type austenitic stainless steel, add copper and cerium elements according to its chemical composition in weight percentage, and make the addition amount of Cu: 0.5%, Ce: 0.01%, according to The 304-type austenitic stainless steel, copper, and cerium element materials after formula weighing are put into the crucible in the induction furnace, fully stirred and mixed, and the alloying element raw materials are heated to 1500 ℃ in the induction furnace and kept at a constant temperature until the sample is in the crucible. The interior is completely melted, smelted, and then water-cooled to room temperature to prepare stainless steel primary billets;

[0029] b. Solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com