Manual tipping-bucket transfer vehicle

A transfer vehicle and tipping bucket technology, which is applied in the field of manual tipping bucket transfer vehicles, can solve the problems of miniature transfer vehicles crossing ditch and difficulty in climbing, and achieves the effect of increasing the load-bearing capacity, increasing the loading capacity, and being widely used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

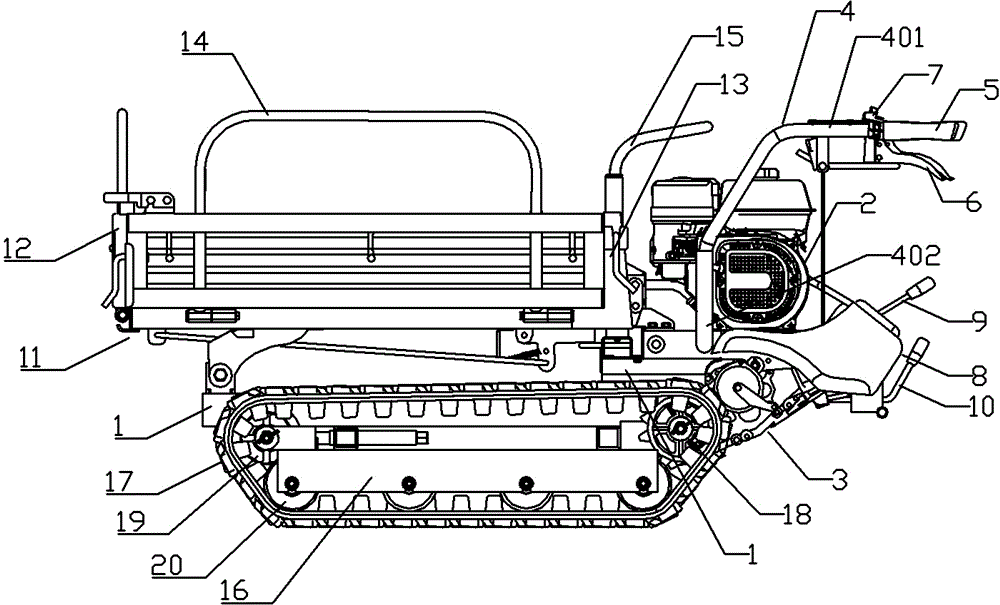

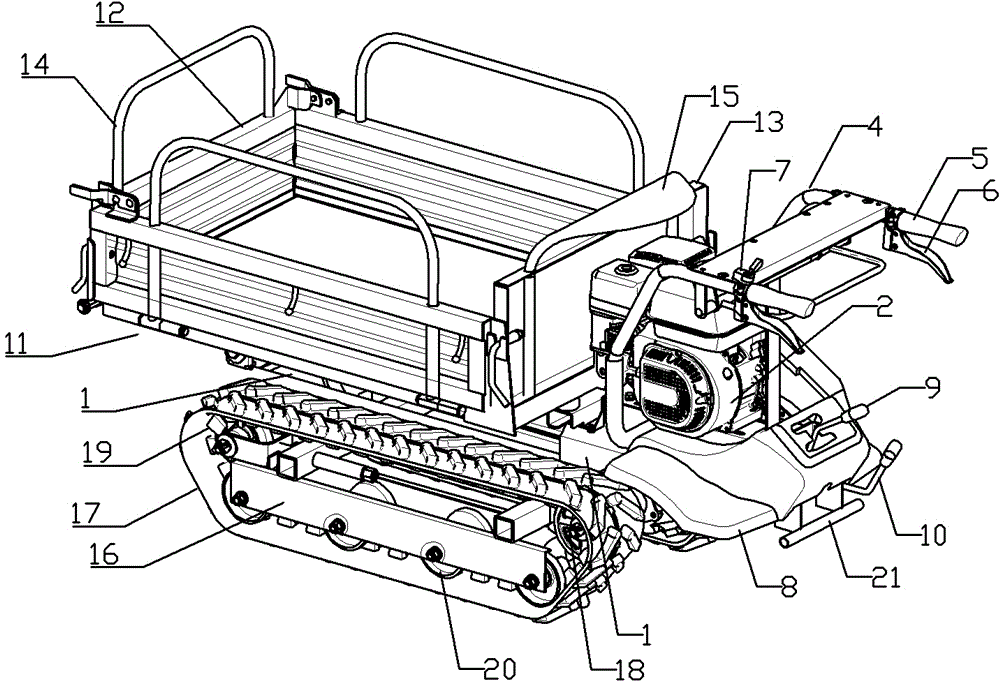

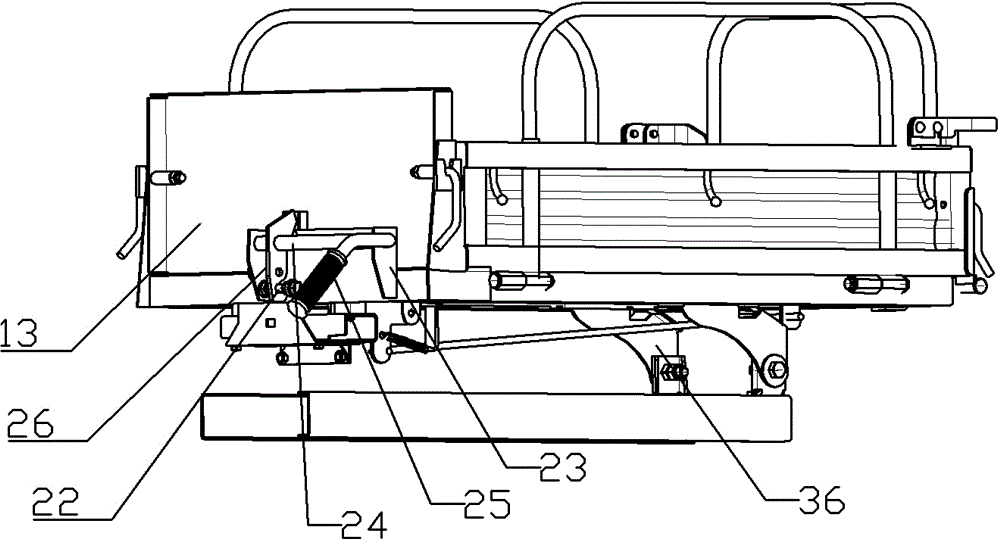

[0020] The reference signs in the drawings of the description include: vehicle frame 1, power unit 2, transmission box body 3, armrest frame 4, V-shaped frame 401, connecting frame 402, handlebar 5, cable handle 6, power start switch 7, cover body 8, shift lever 9, auxiliary transmission rod 10, bucket 11, bucket front fender 12, bucket rear fender 13, auxiliary baffle frame 14, cover body 15, crawler support frame 16, crawler belt 17, driving wheel 18. Tensioning wheel 19, walking wheel 20, pedal bar 21, cross bar 22, leg 36, mounting plate 23, rotating bar 24, operating handle 25, clamping plate 26, horizontal plate 27, bending bar 28, turntable 29, pull Spring 30, seat body 31, pull rod 32, rotating shaft 33, L-shaped plate 34 and strip-shaped hole 35.

[0021] as attached figure 1 and 2 Shown: in the present embodiment, the power unit 2, the transmission box body 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com