Niobium-strengthened wear-resisting surfacing electrode and preparation method thereof

A surfacing welding rod and welding core technology, applied in welding equipment, welding medium, manufacturing tools, etc., can solve the problems of low toughness reserve, fracture and spalling, etc., achieve less welding smoke, stable welding arc, anti-porosity and anti-welding crack ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

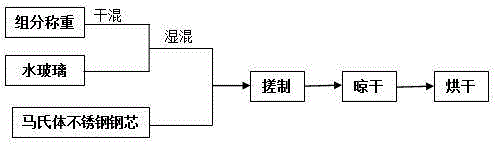

[0036] figure 1 It is a process flow chart of the preparation method described in the present invention.

[0037] Such as figure 1 Shown: the preparation technology of the embodiment of the present invention 1 is:

[0038] (1) Dry blending of the components of the coating: in terms of mass percentage, weigh the components of the coating: marble: 40%; fluorite: 25%; titanium dioxide: 8%; zircon sand: 8%; Feldspar: 6%; rare earth silicon 8%; ferroniobium: after 5%, dry blending;

[0039] (2) Wet mixing: wet mixing the components after the dry mixing of the drug skin with the binder potassium sodium water glass;

[0040] (3) Preparation of niobium-enhanced wear-resistant surfacing electrode: the wet-mixed material and the welding core were rubbed, dried, and dried to obtain the target product. The welding core was 1Cr13 martensitic stainless steel with a diameter of Φ3.2mm, and The thickness of the drug skin is 2.0~2.5mm. After testing, the average hardness of the electrode ...

Embodiment 2

[0042] The preparation technology of the embodiment of the present invention 1 is:

[0043] (1) Dry blending of the components of the coating: in terms of mass percentage, weigh the components of the coating: marble: 45%; fluorite: 25%; titanium dioxide: 8%; zircon sand: 4%; Feldspar: 4%; rare earth silicon: 6%; ferroniobium: 8%, after dry mixing;

[0044] (2) Wet mixing: wet mixing the components after the dry mixing of the drug skin with the binder clay;

[0045] (3) Preparation of niobium-enhanced wear-resistant surfacing electrode: rubbing, drying, and drying the wet-mixed material and the welding core to obtain the target product. The welding core is 2Cr13 martensitic stainless steel with a diameter of Φ4.0mm, and The thickness of the drug skin is 2.0~2.5mm. After testing, the average hardness of the electrode surfacing layer is 55HRC.

Embodiment 3

[0047] The preparation technology of the embodiment of the present invention 1 is:

[0048] (1) Dry mixing of the components of the coating: in terms of mass percentage, weigh the components of the coating Marble: 50%; Fluorite: 15%; Titanium dioxide: 4%; Zircon sand: 8%; Potassium Feldspar: 7%; rare earth silicon: 5%; ferroniobium: after 10%, dry blending;

[0049] (2) Wet mixing: wet mixing the components after dry mixing of the drug skin with the binder slaked lime;

[0050] (3) Preparation of niobium-enhanced wear-resistant surfacing electrode: the wet-mixed material and the welding core were rubbed, dried, and dried to obtain the target product. The welding core was 1Cr13 martensitic stainless steel with a diameter of Φ4.0mm, and The thickness of the drug skin is 2.0~2.5mm. After testing, the average hardness of the electrode surfacing layer is 59HRC.

[0051] The steel core used in the above embodiments has a diameter of Φ3.0-5.0 mm.

[0052] The present invention util...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com