High-entropy alloy welding wire for welding titanium/stainless steel in TIG (Tungsten Inert Gas) mode and application

A high-entropy alloy and stainless steel technology, applied in the direction of welding/cutting media/materials, welding media, welding equipment, etc., can solve the problems of low strength, cracking of brittle intermetallic compounds, etc., and achieve excellent strength, wide composition range, and adaptability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

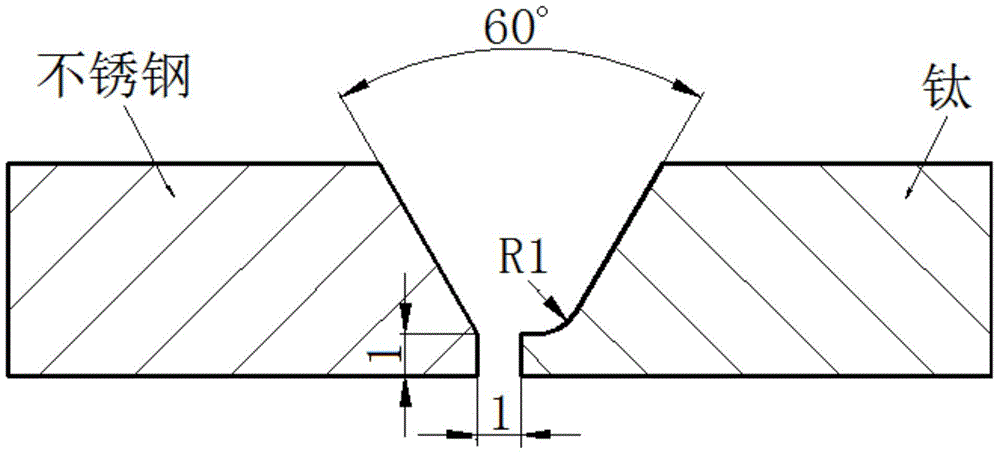

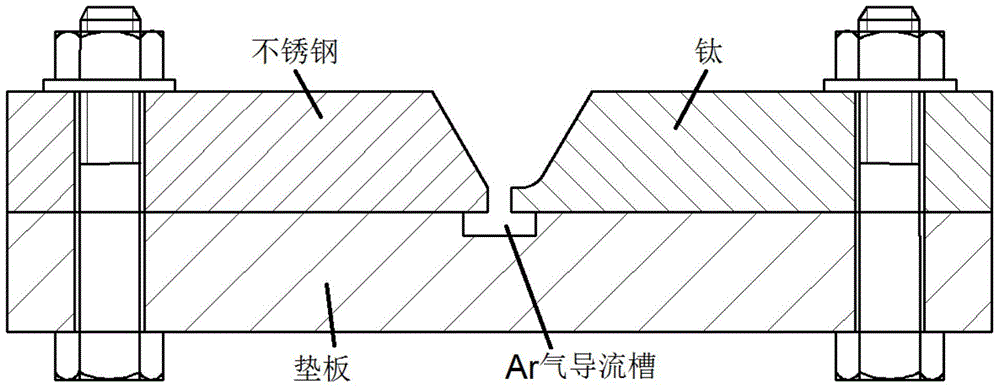

[0032] According to the total atomic percentage of 100%, the content of each component is selected according to 5% of Ti, 5% of Fe, 30% of Cr, 30% of Cu, and 30% of Ni, and a diameter of 1.2 is prepared according to the above-mentioned embodiment. mm of Ti5Fe5Cr30Cu30Ni30 high-entropy alloy wire. TIG welding is used to weld 5mm thick TC4 titanium and 1Cr18Ni9 stainless steel. The welding method is as described above. Speed 60mm / min, Ar gas lag 4s.

[0033] The test found that the weld metal has good fusion and no cracks in the fusion zone. According to the observation of the metallographic structure, the weld structure from the center to the fusion line of the base metal on both sides presents a gradient layered distribution, and the vicinity of the fusion line is dense equiaxed crystal and columnar. Then grow to the center of the weld in the form of dendrites, the phase structure is composed of a single fcc and bcc, and the tensile strength of the welded joint is 220Mpa. ...

Embodiment 2

[0035] According to the total atomic percentage being 100%, the content of each component is selected according to the data of Ti being 5%, Fe being 10%, Cr being 25%, Cu being 30% and Ni being 30%, and the diameter 1.4mm Ti5Fe10Cr25Cu30Ni30 high-entropy alloy wire. TIG welding is used to weld 5mm thick TB5 titanium and 0Cr13 stainless steel. The welding method is as above. Speed 60mm / min, Ar gas lag 3s.

[0036] The test found that the weld metal has good fusion, the joint is full, there are no defects such as surface pores and inclusions, and there is no crack in the fusion zone. According to the observation of the metallographic structure, the weld structure is basically dense equiaxed crystals and dendrites, and the quality of the welded joint is obtained. The tensile strength is 190Mpa.

Embodiment 3

[0038] According to the total atomic percentage of 100%, according to the data of 5% Ti, 8% Fe, 28% Cr, 29% Cu, and 30% Ni, the content of each component element is selected, and prepared according to the above-mentioned embodiment Ti5Fe8Cr28Cu29Ni30 high-entropy alloy welding wire with a diameter of 1.2 mm. TIG welding is used to weld 5mm thick TA2 titanium and 0Cr13 stainless steel. The welding method is as above. Speed 50mm / min, Ar gas lag 4s.

[0039] The test found that the fusion of the weld metal is good, and there are no defects such as cracks, pores and inclusions in the fusion zone. According to the observation of the metallographic structure, the weld structure is basically dense equiaxed crystals and dendrites, and the phase structure is a single fcc solid solution. The tensile strength of the joint is 185Mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com