Preparation process of high-performance refined grain aluminum alloy wires and bars applied to aluminum bolts

A preparation process and aluminum alloy technology, which is applied in the field of preparation process of high-performance fine-grained aluminum alloy wire for aluminum bolts, can solve problems such as bolt corrosion failure, and achieve the effect of improving mechanical properties and refining grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Raw materials such as pure Al, pure Mg, pure Zn, pure copper, AlSi master alloy, AlMn master alloy, AlZr master alloy and other raw materials were smelted into ingots in an inverting melting furnace. The chemical composition of the ingots is shown in Table 1.

[0031] Chemical composition of the alloy in table 1 (wt.%)

[0032] Si

Fe

Cu

mn

Mg

Cr

Zn

Ti

Zr

Al

1.08

0.09

0.46

0.53

0.65

0.02

0.18

0.02

0.06

Remain

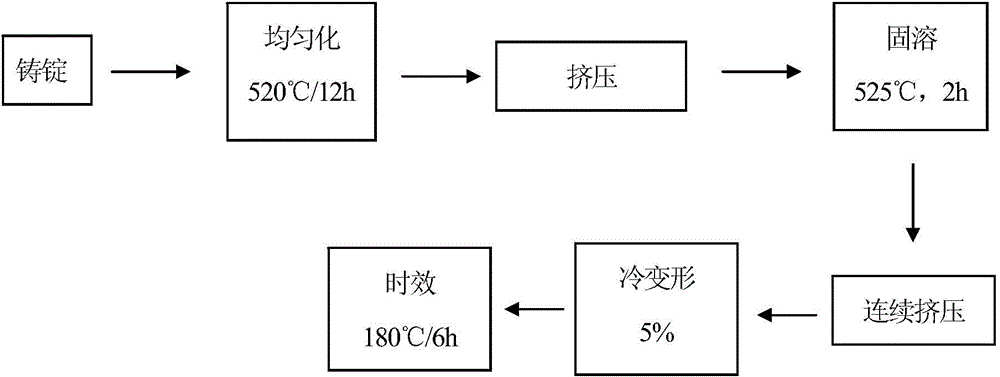

[0033] The specific production process such as figure 1 , the actual operation steps are as follows:

[0034] (1) Carry out homogenization heat treatment to aluminum alloy ingot between 500~540 ℃, holding time 12~24h, air cooling (in this embodiment, homogenization temperature 520 ℃, time 12h);

[0035] (2) Extrude the cast ingot into a bar at 420-470°C, the extrusion ratio is 30.0-100.0, and air-cooled (in this embodiment, the extrusion temperature is 450°C, the cont...

Embodiment 2

[0045] Use pure Al, pure Mg, pure Zn, pure copper, AlSi master alloy, AlMn master alloy, AlZr master alloy and other raw materials for semi-continuous casting, the size of the crystallizer is Φ100mm, the casting speed is 10mm / min, the chemical composition of the ingot is shown in the table 3.

[0046] Chemical composition of the alloy in table 3 (wt.%)

[0047] Si

[0048] Specific steps are as follows:

[0049] (1) Carry out homogenization heat treatment to aluminum alloy ingot between 500~540 ℃, holding time 12~24h, air cooling (in this embodiment, homogenization temperature 530 ℃, time 18h);

[0050](2) Extrude the cast ingot into rods between 420 and 470°C, with an extrusion ratio of 30.0 to 100.0, and air cooling (in this embodiment, the extrusion temperature is 430°C, and the continuous extrusion outlet size is Φ10mm (2 branch), the extrusion ratio is 50);

[0051] (3) Carry out solid solution treatment to the rod, the treatment system is 520-540°C, heat pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com