Method for flotation recovery of gold from gold-extracting tailings obtained from preliminary biooxidation-carbon-in-pulp process

A technology for pre-oxidation and recovery of gold, applied in the field of comprehensive utilization of resources, can solve the problems of unpublished specific names of leaching aids, large amount of leaching aids, and high cost, and achieve the goal of improving floatability, increasing recovery rate, and realizing recovery. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The analysis results of the tailings of a biological preoxidation-carbon slurry method are as follows: the content of Au is 3.65g / t, the content of Ag is 2.10g / t, the content of Cu is 0.05%, the content of Pb is 0.12%, and the content of C is 0.42%. Occurrence in granular state, pyrite is the main carrier mineral of gold.

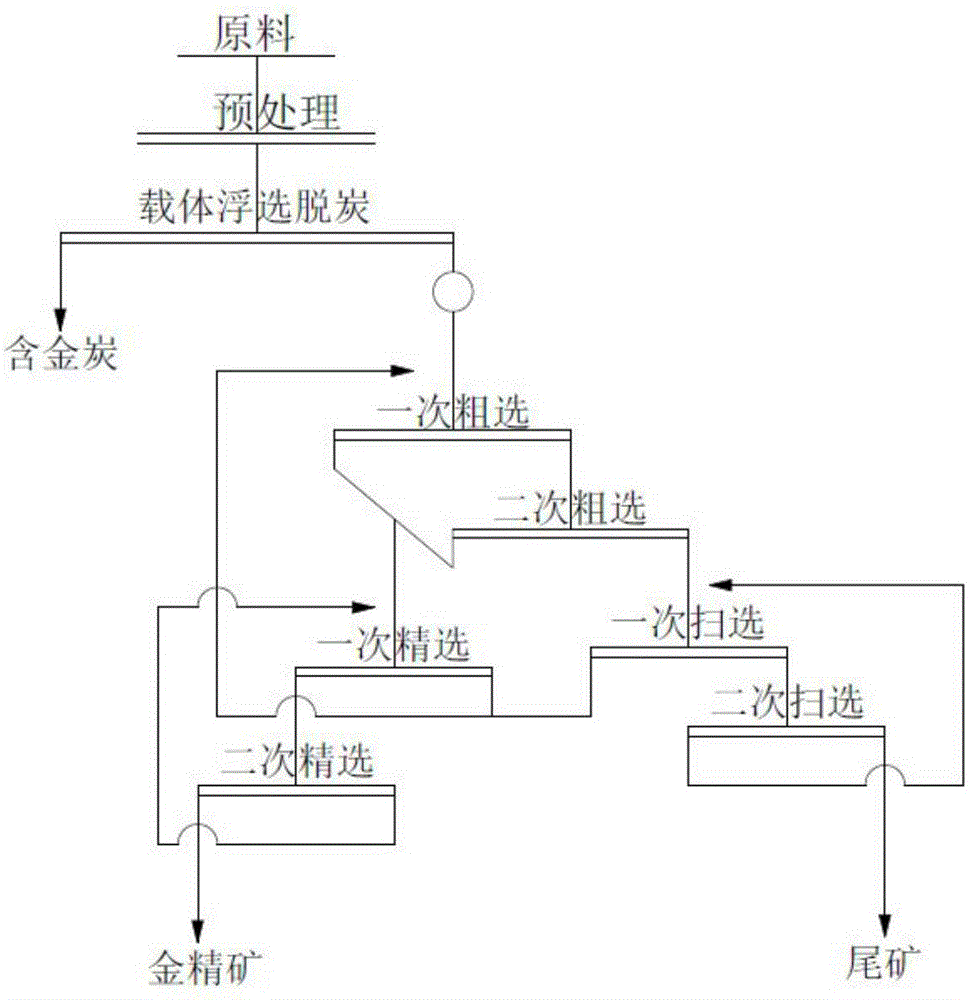

[0045] use as figure 1 The shown flow process carries out flotation recovery gold, and concrete steps are:

[0046] (1) Pretreatment

[0047] The biological pre-oxidation-carbon leaching method gold extraction tailings and water were prepared into a slurry with a mass concentration of 40%, and 100 g / t of isooctyl alcohol was added, and the rotation speed was 1700 r / min and stirred for 8 minutes; Modified activated carbon 1.5kg / t, stirring for 15min at a rotational speed of 1700r / min.

[0048] (2) Carrier flotation decarbonization

[0049] Adjust the pulp in step (1) to a pulp concentration of 25%, add 60 g / t of kerosene, stir for 3 min at a rotat...

Embodiment 2

[0066] The tailings of a biological preoxidation-carbon slurry method were tested and analyzed, and the results are as follows: Au content 4.07g / t, C content 0.39%, Pb content 0.08%, Zn content 0.15%, gold is mainly in the state of fine particles The main carrier minerals of gold are pyrite and arsenite.

[0067] use as figure 1 The shown flow process carries out flotation recovery gold, and concrete steps are:

[0068] (1) Pretreatment

[0069] The biological pre-oxidation-carbon leaching method gold extraction tailings and water were prepared into a slurry with a mass concentration of 50%, and 150 g / t of isooctyl alcohol was added, and the rotation speed was 1900 r / min and stirred for 12 minutes; Modified activated carbon 2.5kg / t, stirring for 20min at a rotational speed of 1900r / min.

[0070] (2) Carrier flotation decarbonization

[0071] Adjust the pulp in step (1) to a pulp concentration of 30%, add 120 g / t of kerosene, stir for 5 min at a rotational speed of 1500 r / m...

Embodiment 3

[0088] The test analysis results of the tailings of a biological preoxidation-carbon slurry method are: Au content 3.20g / t, C content 0.31%, Pb content 0.11%, Cu content 0.03%, Zn content 0.07%, gold is mainly in the state of fine particles Inlaid, the main carrier minerals of gold are arsenopyrite and pyrite.

[0089] use as figure 1 The shown flow process carries out flotation recovery gold, and concrete steps are:

[0090] (1) Pretreatment

[0091] The biological pre-oxidation-carbon leaching method gold extraction tailings and water were prepared into a slurry with a mass concentration of 45%, and 120 g / t of isooctyl alcohol was added, and the rotation speed was 1800 r / min and stirred for 11 minutes; Modified activated carbon 2.0kg / t, stirring for 18min at a rotational speed of 1750r / min.

[0092] (2) Carrier flotation decarbonization

[0093] Adjust the pulp in step (1) to a pulp concentration of 27%, add 80 g / t of kerosene, stir for 4 min at a rotational speed of 140...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com