High performance epoxy resin waterproof coating

A technology of epoxy resin and waterproof coating, applied in the direction of epoxy resin coating, coating, etc., can solve the problem that the elongation at break cannot be obtained, and achieve the effect of improving flexibility and high elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

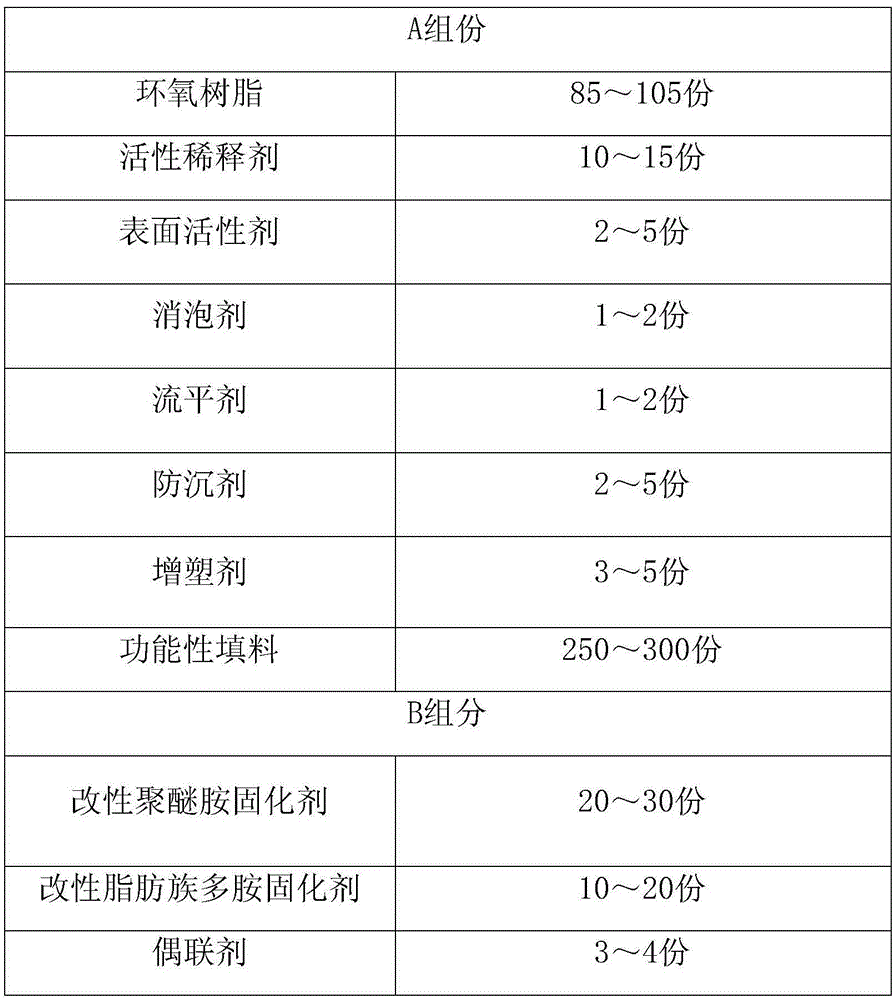

Method used

Image

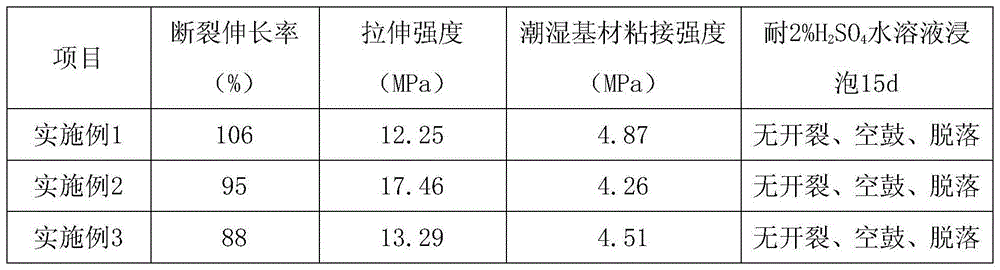

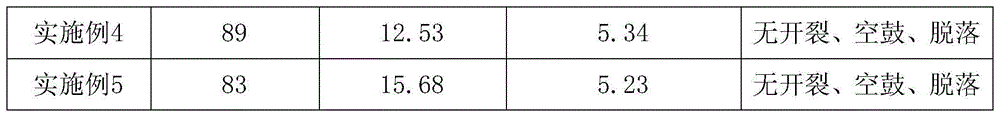

Examples

Embodiment 1

[0023] 95 parts of bisphenol A liquid epoxy resin E44, 12 parts of polypropylene glycol diglycidyl ether, 2 parts of surfactant byk-104s, 1 part of silicone defoamer BYK-A530, 1 part of leveling agent modified organic Silicon leveling agent BYK310, 3 parts of plasticizer amino-terminated nitrile rubber ATBN, 252 parts of functional fillers including 50 parts of barium sulfate, 50 parts of mica powder, 50 parts of talcum powder, 50 parts of white cement, 50 parts of heavy calcium, 2 parts of anti-sedimentation agent organic bentonite, mixed evenly to obtain component A;

[0024] 20 parts of modified polyether amine curing agent amino-terminated polyoxypropylene ether, 12 parts of ether modified hexamethylenediamine fatty amine curing agent, 3 parts of coupling agent aminotriethoxysilane, 1 part of anti-settling agent organic bentonite, Mix well to get B component.

[0025] When in use, mix components A and B in a ratio of 10:1 and apply it evenly on the concrete cement surface...

Embodiment 2

[0027] Mix 95 parts of bisphenol A liquid epoxy resin E51, 10 parts of polypropylene glycol diglycidyl ether, 2 parts of surfactant byk-104s, 1 part of mixture of defoamer modified silicone BYK-A530 and DEFOM6500, 1 part of flow Leveling agent modified silicone LEVASLIP810, 3 parts of hydroxy-terminated nitrile rubber CTBN, 280 parts of functional fillers including 50 parts of barium sulfate, 50 parts of 800 mesh mica powder, 50 parts of 400 mesh talcum powder, 50 parts of white cement of grade 42.5 , 50 parts of 325 mesh heavy calcium, 30 parts of 80-120 mesh quartz sand, 2 parts of anti-sedimentation agent organic bentonite, mix well to obtain the mixture of component A;

[0028] Mix 22 parts of modified polyetheramine curing agent amino-terminated polyoxypropylene ether and amino-terminated polyoxyethylene ether mixture, 15 parts of ether-modified ethylenediamine curing agent, 3 parts of coupling agent amino-terminated triethoxysilane, aniline Triethoxysilane mixture 1 part...

Embodiment 3

[0031] 95 parts of bisphenol F epoxy resin F652, 10 parts of ethylene glycol diglycidyl ether, 2 parts of wetting agent HX-4020, 1 part of defoamer DEFOM6500, 1 part of fluorine-modified acrylic leveling agent LEVASLIP839 , 3 parts of plasticizer epoxy-based nitrile rubber ETBN, 300 parts of functional fillers include 20 parts of talc powder, 20 parts of 325 mesh quartz powder, 20 parts of 400 mesh heavy calcium, 240 parts of 40-80 mesh quartz sand, one part Mix the modified urea solution DeuRheo2810 evenly to obtain component A;

[0032] Mix 22 parts of modified polyetheramine curing agent with amino-terminated polyoxyethylene ether, 15 parts of ether-modified diethylenetriamine curing agent, 3 parts of coupling agent-terminated aminotriethoxysilane, and 1 part of polyethylene wax with modified The mixture of urea solution, mixed evenly to obtain component B;

[0033] When in use, apply components A and B in a ratio of 25:3 evenly on the concrete cement surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com