Coloring master batch for profile protective film and preparation method thereof

A technology for coloring masterbatch and protective film, applied in the field of plastic additives, can solve the problems of low volatilization of small molecular organic compounds, high dispersibility, large addition ratio, etc., and achieves good processing stability, good dispersibility, and small viscosity change. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

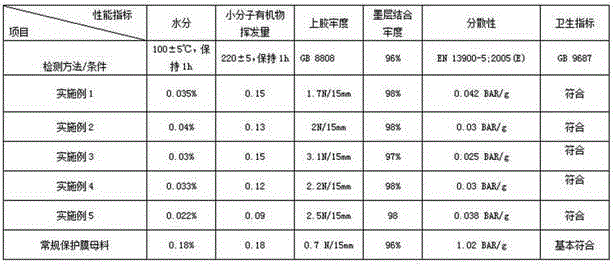

Examples

Embodiment 1

[0046] A coloring masterbatch for a profile protective film, comprising raw materials of the following weight: 60kg of titanium dioxide, 19.5kg of LLDPE, 10kg of mPE, 0.5 kg of silicone, and 10kg of EVA; the volatile amount of small molecular organic compounds of the titanium dioxide is 0.12%; The titanium dioxide is rutile-type titanium dioxide, and its average particle size is 0.2 μm.

[0047] The detection method of the volatile amount of small molecule organic compounds is as follows:

[0048] ① Weigh the desiccator dried to constant weight on the electronic balance, the mass is m 0 ;

[0049] ②Add and weigh 3 to 5g of the substance to be tested in the drying dish, weigh together with the drying dish, and record the mass m 1 , put the desiccating dish containing the object to be tested in a drying oven, pre-treat at 100±5°C to eliminate moisture interference, and after processing to constant weight, weigh and record m 2 ;

[0050] ③Then put the desiccating dish contain...

Embodiment 2

[0053] A coloring masterbatch for a profile protective film, comprising raw materials of the following weight: 75kg of titanium dioxide, 15.7kg of LLDPE, 5kg of mPE, 0.3 kg of silicone, and 4kg of EVA; the volatile amount of small molecular organics of the titanium dioxide is 0.08%; The titanium dioxide is rutile titanium dioxide, and its average particle size is 0.25 μm.

[0054] Among the raw materials of this embodiment: the volatilization amount of small molecule organic matter of EVA is 0.1%; the volatilization amount of small molecule organic matter of LLDPE is 0.11%, and the melt mass flow rate is 60g / 10min; The volatile amount of ketone small molecular organic compounds is 0.05%.

[0055] In this embodiment, the detection method of the volatile amount of small molecule organic matter in raw materials is the same as that in Embodiment 1. The equipment used for the detection of the melt mass flow rate of LLDPE is XWR-400, and the weight of the material flowing out from ...

Embodiment 3

[0057] A coloring masterbatch for profile protection film, including the following raw materials: 70kg of titanium dioxide, 15kg of LLDPE, 7kg of mPE, 0.3 kg of silicone, and 8kg of EVA; %, the average particle size is 0.22μm, and the equipment used to detect the particle size of titanium dioxide is JL-1177 laser particle size distribution tester.

[0058] Among the raw materials of this embodiment: the volatilization amount of small molecule organic matter of EVA is 0.11%; the volatilization amount of small molecule organic matter of LLDPE is 0.1%, and the melt mass flow rate is 55g / 10min; The volatile amount of ketone small molecular organic compounds is 0.03%. Wherein, the detection method of the small molecular organic matter of the raw material is the same as that of Example 1, and the detection of the melt mass flow rate of LLDPE is the same as that of Example 2.

[0059] In this embodiment, the mPE is Enable TMmPE produced by ExxonMobil Chemical Company, which has the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com