Preparation method of super-hydrophobic surface of room temperature vulcanized silicone rubber

A technology of super-hydrophobic surface and room temperature vulcanization, which is applied in the direction of coating, etc., can solve the problems of cumbersome steps, high equipment requirements, complicated preparation process, etc., and achieve the effect of expanding application range, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

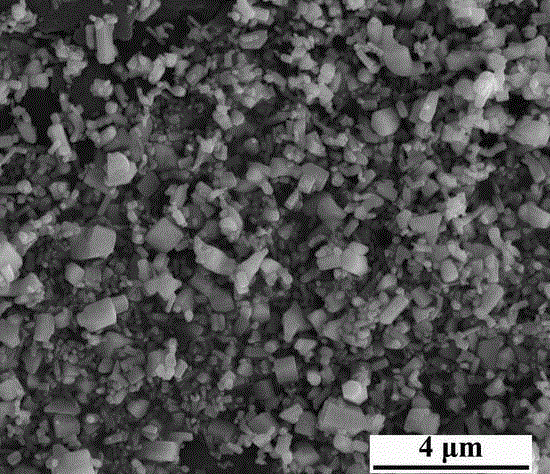

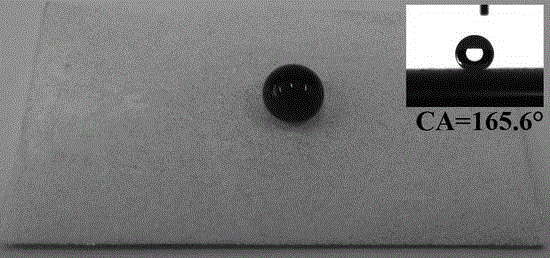

[0019] Dissolve 1 mL of n-dodecanethiol in 50 mL of n-hexane at room temperature; then add 10 g of zinc oxide powder with a particle size of 200 to 400 nm to this solution, and magnetically stir to form a suspension; after continuous stirring for 30 min, The suspension is centrifuged and the solid is vacuum dried to constant weight to obtain hydrophobic zinc oxide powder.

[0020] 10 g α, ω-dihydroxy polydimethylsiloxane with a viscosity of 10000 cp, 0.5 g curing agent tetraethoxysilane and 0.05 g catalyst di-n-butyltin dilaurate were dissolved in 10 mL n-hexane at room temperature In the process, the room temperature vulcanized silicone rubber precursor solution is obtained. Then pour the precursor solution on the surface of the flat glass, and use a glass rod to unfold it into a shape of 2 cm×5 cm. After being leveled naturally, it is vacuum degassed at room temperature for 5 min. Put 3 g of hydrophobic zinc oxide powder into a 200-mesh stainless steel sample sieve, sieve it u...

Embodiment 2

[0022] Dissolve 50 μL of n-dodecyltriethoxysilane in 50 ml of absolute ethanol at room temperature; then add 10 g of diatomaceous earth powder with a particle size of 10 μm to this solution, and magnetically stir to form a suspension; continue; After stirring for 30 min, the suspension was centrifuged for analysis, and the solid was vacuum dried to a constant weight to obtain hydrophobic diatomaceous earth powder.

[0023] 10 g α, ω-dihydroxy polydimethylsiloxane with a viscosity of 10000 cp, 0.5 g curing agent tetraethoxysilane and 0.05 g catalyst di-n-butyltin dilaurate were dissolved in 10 mL n-hexane at room temperature In the process, the room temperature vulcanized silicone rubber precursor solution is obtained. Then pour the precursor solution on the surface of the flat glass, and use a glass rod to unfold it into a shape of 5 cm×10 cm. After it is leveled naturally, it is vacuum degassed at room temperature for 5 min. Put 5 g of hydrophobic diatomaceous earth powder into...

Embodiment 3

[0025] Dissolve 20 μL of n-octadecyltrichlorosilane in 50 ml of absolute ethanol at room temperature; then add 5 g of silica particles with a particle size of 12 nm (Meteorological White Carbon Black, Model M5, Shanghai Cabot Chemical Co., Ltd.), magnetically stirred to form a sol; this sol was dried in an electric blast drying oven at 60 ℃ for 24 hours to obtain hydrophobic silica powder.

[0026] Dissolve 5 g α, ω-dihydroxy polydimethylsiloxane with a viscosity of 5000 cp, 0.25 g curing agent tetraethoxysilane and 0.02 g catalyst di-n-butyltin dilaurate in 5 mL n-hexane at room temperature In the process, the room temperature vulcanized silicone rubber precursor solution is obtained. Then pour the precursor solution on the surface of the flat glass, and use a glass rod to unfold it into a shape of 10 cm×10 cm. After it is leveled naturally, it is vacuum degassed at room temperature for 5 min. Put 2 g of hydrophobic silica powder into a 500-mesh stainless steel sample sieve, si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Static contact angle | aaaaa | aaaaa |

| Static contact angle | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com