Low-viscosity, low-exothermicity, high-strength, high-toughness epoxy resin/curing agent system for liquid infusion molding of composite material

A technology of epoxy resin and liquid infusion, applied in the field of epoxy resin, which can solve the problems of fast reaction speed, overheating of curing system, and danger caused by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

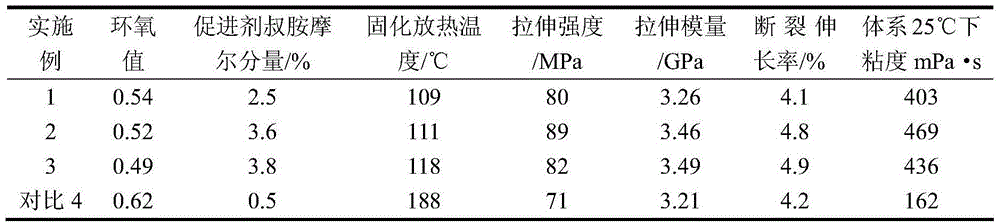

Embodiment 1

[0026] Mix benzylamine and bisphenol F epoxy resin epoxy groups in a molar ratio = 1:20 in a flask, place in a constant temperature oil bath and stir at a medium speed, react at a temperature of 80-100°C for 4 hours, and prepare the prepared The amine-modified epoxy resin was collected for later use.

[0027] 100g of amine-modified epoxy resin, 5g of 1,4-butanediol glycidyl ether, 91g of hexahydrophthalic anhydride, and 0.27g of DMP-30 accelerator, stir well, vacuumize to remove air bubbles, press 90℃ / 2h+130 °C / 2h pouring and curing, the cured epoxy resin can be obtained, and the curing exothermic peak temperature and properties are listed in Table 1.

Embodiment 2

[0029] Mix benzylamine and bisphenol F epoxy resin epoxy groups in a flask at a molar ratio = 1:15, place in a constant temperature oil bath and stir at a medium speed, react at a temperature of 80-100°C for 4 hours, and prepare the prepared The amine-modified epoxy resin was collected for later use.

[0030] Amine-modified epoxy resin 100g, 1,4-butanediol glycidyl ether 5g, hexahydrophthalic anhydride and methyl hexahydrophthalic anhydride mixed acid anhydride 88g according to the mass ratio of 1:1, and DMP-30 accelerator 0.24g, stirring Evenly, vacuumize to remove air bubbles, and pour and cure at 90°C / 2h+130°C / 2h to obtain a cured epoxy resin. The curing exothermic peak temperature and properties are listed in Table 1.

Embodiment 3

[0032] Mix benzylamine and bisphenol F epoxy resin epoxy groups in a flask at a molar ratio = 1:15, place in a constant temperature oil bath and stir at a medium speed, react at a temperature of 80-100°C for 4 hours, and prepare the prepared The amine-modified epoxy resin was collected for later use.

[0033] Amine-modified epoxy resin 100g, polyethylene glycol glycidyl ether 10g, hexahydrophthalic anhydride and methyl hexahydrophthalic anhydride mixed acid anhydride 87g by mass 1:1, and DMP-30 accelerator 0.26g, stir evenly, vacuumize Remove air bubbles, that is, pour and cure at 90°C / 2h+130°C / 2h to obtain a cured epoxy resin. The peak exothermic temperature and properties of curing are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com