Process method for preparing polyformaldehyde dimethyl ether from methanol

A technology of polyoxymethylene dimethyl ether and process method, which is applied in chemical instruments and methods, sustainable manufacturing/processing, chemical industry, etc., can solve the problems of low yield, and achieve low production cost, good technical effect, and high yield and the effect of high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

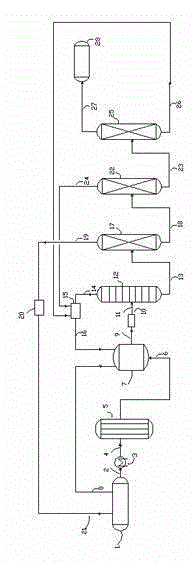

Method used

Image

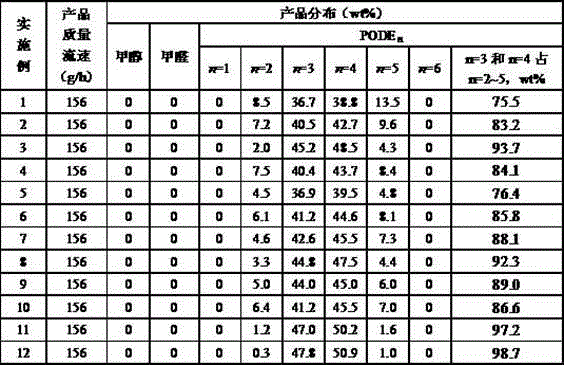

Examples

Embodiment 1

[0026] Fill 150g in the fixed bed reactor 5, ferromolybdenum catalyst (composed of molybdenum oxide, iron oxide, iron molybdate in molar ratio 5:1:1), fill 150g HZSM-5 molecular sieve (Si / Al=15), purging device with nitrogen, liquid phase methanol is fed into fixed bed reactor 5 after being heated and vaporized and mixed with preheated air, and the volumetric space velocity of air is 4000h -1 , the feed rate of methyl alcohol is 93.75g / h, the operating temperature of fixed bed reactor 5 is 380 ℃, and the pressure is 1MPa; For the mixture of water methanol and polyoxymethylene dimethyl ether (n=1,2,5,6), the feed rates are 62.5g / h and 111.75g / h respectively. The output from the pre-mixing tank 7 enters the reactive distillation column 12, and its operating conditions are that the reaction temperature is 80° C. and the reaction pressure is 1.0 MPa.

[0027] The methylal is discharged from the top of the reactive distillation tower 12 (stream 14), and the operating pressure is ...

Embodiment 2

[0030] Fill 150g in the fixed bed reactor 5, ferromolybdenum catalyst (composed of molybdenum oxide, iron oxide, iron molybdate in molar ratio 5:1:1), fill 300g HZSM-5 molecular sieve (Si / Al=15), purging device with nitrogen, liquid phase methanol is fed into fixed bed reactor 5 after being heated and vaporized and mixed with preheated air, and the volumetric space velocity of air is 4000h -1 , the feed rate of methyl alcohol is 93.75g / h, the operating temperature of fixed bed reactor 5 is 380 ℃, and the pressure is 1MPa; For the mixture of water methanol and polyoxymethylene dimethyl ether (n=1,2,5,6), the feed rates are 62.5g / h and 87.2g / h respectively. The output from the pre-mixing tank 7 enters the reactive distillation tower 12, and its operating conditions are that the reaction temperature is 100° C. and the reaction pressure is 1.0 MPa.

[0031] The methylal is discharged from the top of the reactive distillation tower 12 (stream 14), and the operating pressure is 1 ...

Embodiment 3

[0034] Fill 150g in the fixed bed reactor 5, ferromolybdenum catalyst (composed of molybdenum oxide, iron oxide, iron molybdate in molar ratio 5:1:1), fill 300g HZSM-5 molecular sieve (Si / Al=15), purging device with nitrogen, liquid phase methanol is fed into fixed bed reactor 5 after being heated and vaporized and mixed with preheated air, and the volumetric space velocity of air is 4000h -1 , the feed rate of methanol is 93.75g / h, the operating temperature of the fixed bed reactor 5 is 380°C, and the pressure is 1MPa; For the mixture of water methanol and polyoxymethylene dimethyl ether (n=1,2,5,6), the feed rates are 62.5g / h and 87.2g / h respectively. The output from the pre-mixing tank 7 enters the reactive distillation column 12, and its operating conditions are that the reaction temperature is 120° C. and the reaction pressure is 1.0 MPa.

[0035] The methylal is discharged from the top of the reactive distillation tower 12 (stream 14), and the operating pressure is 1 M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com