Preparation method of highly-catalytic type nanometer cerium oxide

A nano-cerium oxide, catalytic technology, applied in the direction of chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of high equipment requirements, high cost, and large environmental impact, and achieve cost reduction and excellent photocatalytic effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

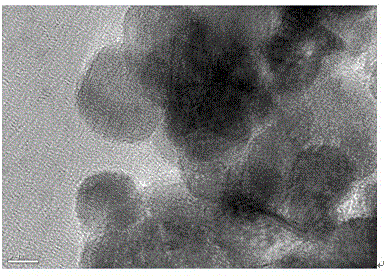

[0015] Mix 6.8mL of ammonia water and distilled water to prepare an ammonia solution with a concentration of 2mol / L, and mix 0.634g of cerium acetate with distilled water to prepare a cerium acetate solution with a concentration of 0.02mol / L. The 100ml beaker and the 250ml beaker containing the 2mol / L ammonia solution are placed in an airtight container at the same time and sealed. And put it in a microwave oven, heat at low power 160w for 35 minutes; the ammonia vapor generated by heating reacts with cerium acetate solution to produce cerium hydroxide precipitate, take it out, wash it with absolute ethanol, and centrifuge to obtain the precipitate. The precipitate was dried at 60 °C for 12 h. Finally, burn at 500°C for 5 hours in a muffle furnace to obtain figure 1 Nanoscale ceria shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com