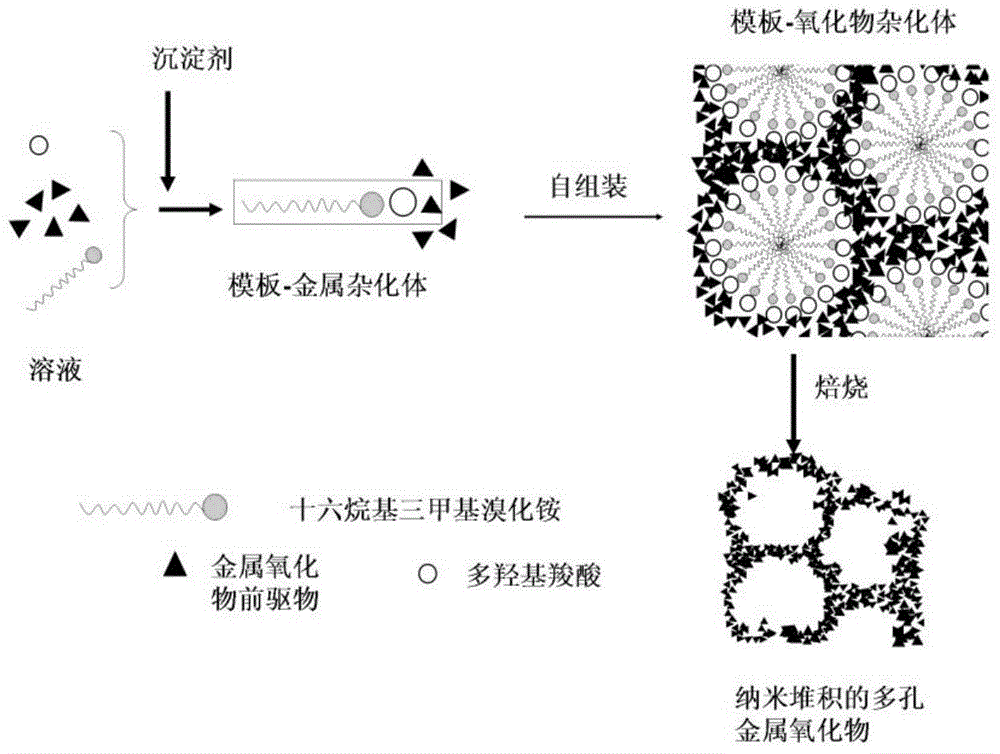

Preparation method of porous metallic oxide stacked by nano-particles

A porous metal and nanoparticle technology, applied in the direction of magnesium oxide, ferrous oxide, nanotechnology, etc., can solve the problems of expensive use, complicated process, high cost, etc., and achieve the effect of reducing cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Mesoporous alumina (abbreviated as MA) uses cetyltrimethylammonium bromide (CTAB, analytically pure) as a template agent, sodium tartrate (ST, analytically pure) or sodium citrate (analytical pure) or succinate Sodium acid (analytical pure) is auxiliary agent, Al 2 (SO 4 ) 3 .18H 2 O (analytical pure) is the aluminum source, and urea is the precipitating agent. During the synthesis, the molar composition of the solution is first determined as: Al 2 (SO 4 ) 3 / CTAB / ST / CO(NH) 2 / H2O=1.0 / 0.1 / x / 2 / 140, the sodium tartrate / aluminum molar ratio (x) varied from 0 to 0.5. Then the solution was transferred into a polytetrafluoroethylene autoclave, and the reaction kettle was maintained at 165°C for 3 hours, then cooled to room temperature, filtered, washed and then dried at 80°C for 12 hours to obtain a sample. The obtained samples are denoted as MAT-x. The prepared mesoporous aluminum oxide was calcined at 550°C to remove the template and the obtained alumina was denote...

Embodiment 2

[0026] Mesoporous magnesia uses octadecyltrimethylammonium bromide (OTAB analytical pure) as template agent, sodium tartrate (ST, analytical pure) as auxiliary agent, Mg(NO 3 ) 2 (Analytical pure) is the magnesium source, and urea or ammonia water is the precipitating agent. During the synthesis, the molar composition of the solution is firstly determined as: Mg(NO 3 ) 2 / OTAB / ST / CO(NH) 2 / H2O=1.0 / 0.2 / x / 2 / 120, the molar ratio (x) of sodium tartrate / magnesium varies from 0 to 0.4. Then the solution was transferred into a polytetrafluoroethylene autoclave, and the reaction kettle was maintained at 120° C. for 2 hours, then cooled to room temperature, filtered, washed and then dried at 100° C. for 12 hours to obtain a sample. The obtained samples were denoted as MMgO-x. The prepared mesoporous magnesium oxide was calcined at 500°C to remove the template and the obtained magnesium oxide was denoted as MMgO-xC.

[0027] T1: OTAB (0.005mol), Mg (NO 3 ) 2 (0.025mol), CO(NH) ...

Embodiment 3

[0033] Mesoporous copper oxide uses cetyltrimethylammonium bromide (CTAB analytical grade) as template agent, sodium citrate (CA, analytical grade) as auxiliary agent, CuSO 4 .5H 2 O (analytical pure) is the copper source, and ammonia water is the precipitating agent. During the synthesis, the molar composition of the solution is first determined as: CuSO 4 / CTAB / CA / NH 3 / H 2 O=1.0 / 0.1 / x / 3 / 120, the sodium citrate / copper molar ratio (x) varied from 0 to 0.4. Then the solution was transferred to a glass round bottom flask, a reflux condenser was installed, the solution was refluxed at 100°C for 2 hours, then cooled to room temperature, filtered, washed and then dried at 100°C for 12 hours to obtain a sample. The obtained samples are denoted as MCuO-x. The prepared mesoporous copper oxide was calcined at 550°C to remove the template and the obtained copper oxide was denoted as MCuO-xC.

[0034] T1: CTAB (0.005mol), CuSO 4 (0.05mol) and a certain amount of sodium citrate we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com