Nanometer artificial bone scaffold with structure similar to that of natural bone and preparation method thereof

A technology of artificial bone and natural bone, applied in the direction of bone implants, etc., to achieve the effect of good biomechanical strength, simple production method and high proliferation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

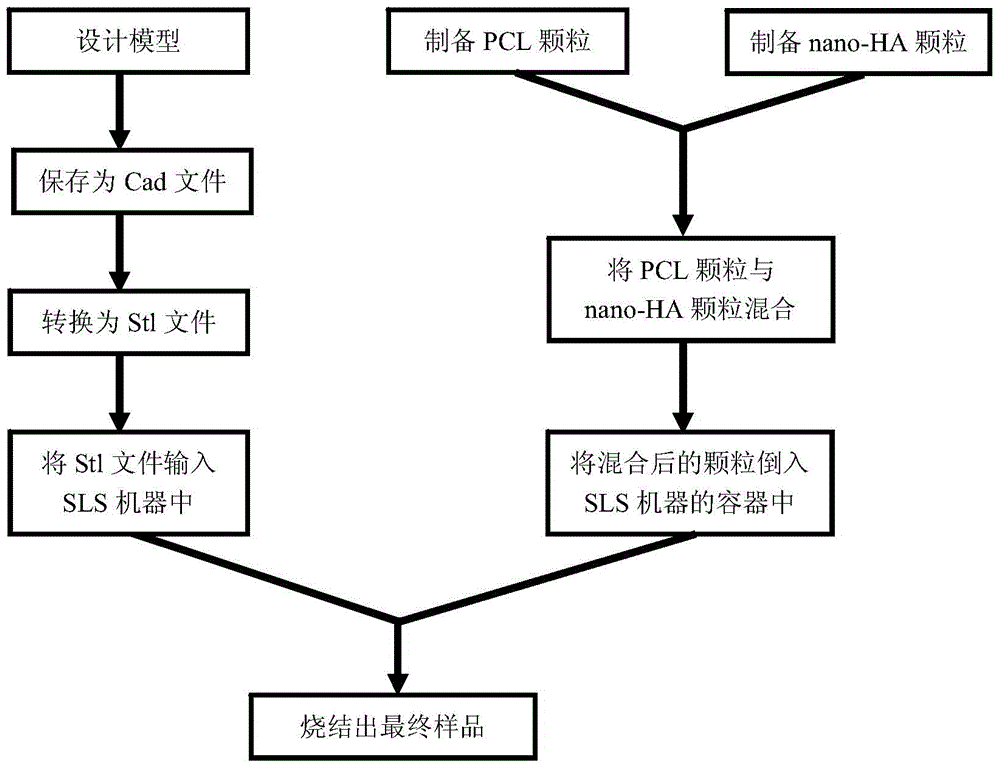

[0046] Embodiment 1: Preparation of nano-hydroxyapatite / polycaprolactone artificial bone scaffold similar to natural bone structure of 10%HA

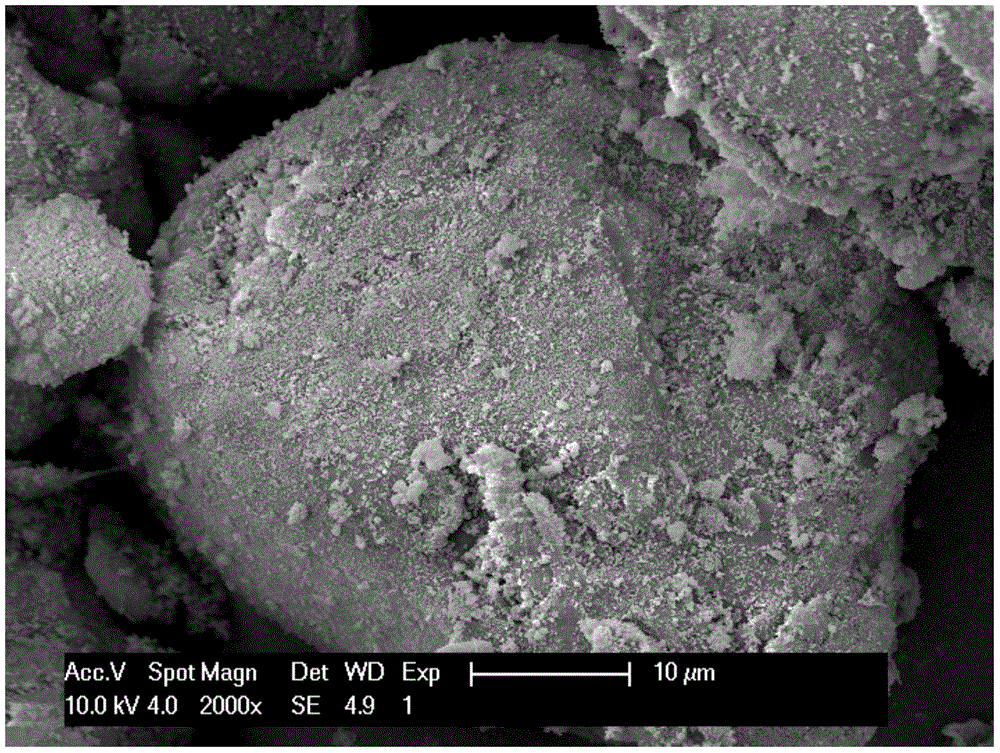

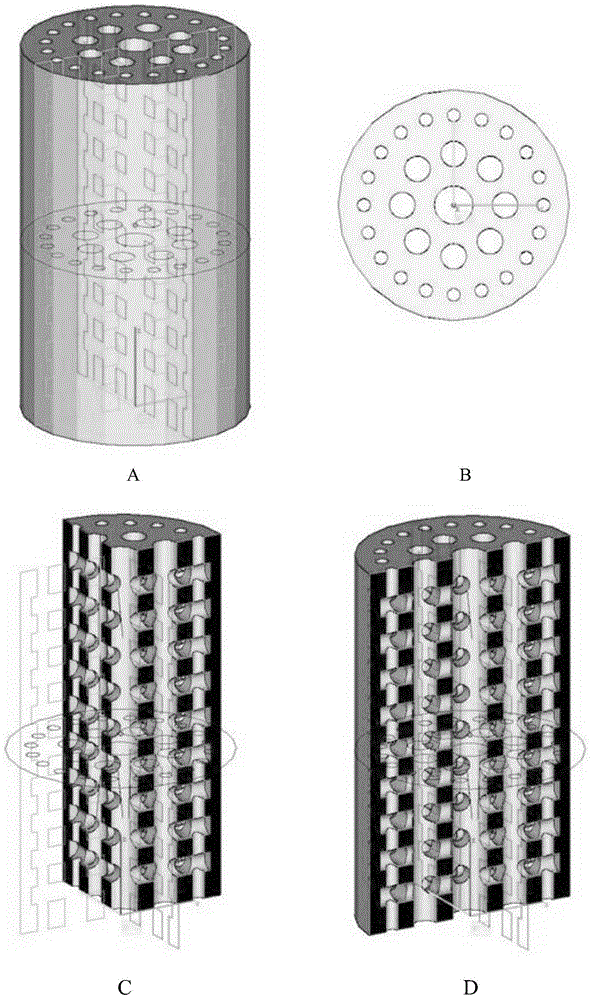

[0047] Using liquid nitrogen as a refrigerant, the polycaprolactone particles with a diameter of about 3-5 mm were crushed into particles of 110±20 μm by cryogenic crushing technology for later use. 1 kg of nano-HA powder with a particle size of 40 ± 10 nm was mixed with 9 kg of prepared PCL powder to obtain 10 kg of nano-HA / PCL mixed powder with a mass ratio of HA of 10%. Pour the nano-HA / PCL mixed powder into the container of the V-type mixer, and rotate forward (clockwise) and reverse (counterclockwise) for 1 hour each to obtain a uniformly mixed nano-HA / PCL mixed powder (see figure 2 ). Use the 3D graphic design software (Unigraphics NX4.0, American EDS company) on the computer to design the 3D model of computer aided design (COMPUTER AIDED DESIGN, CAD). Artificial bone scaffold models of natural bone structures (see image 3 ),...

Embodiment 2

[0048] Example 2: Preparation of nano-hydroxyapatite / polycaprolactone artificial bone scaffold with 20% HA transverse gradient pore structure.

[0049] Using liquid nitrogen as a refrigerant, the polycaprolactone particles with a diameter of about 3-5 mm were crushed into particles of 110±20 μm by cryogenic crushing technology for later use. 2 kg of nano-HA powder with a particle size of 40 ± 10 nm was mixed with 8 kg of prepared PCL powder to obtain 10 kg of nano-HA / PCL mixed powder with a mass ratio of HA of 10%. Pour the nano-HA / PCL mixed powder into the container of the V-shaped mixer, and rotate forward (clockwise) and reverse (counterclockwise) for 1 hour each to obtain a uniformly mixed nano-HA / PCL mixed powder. Use 3D graphics design software on the computer to design a 3D model of computer aided design (COMPUTER AIDED DESIGN, CAD). The outermost layer is a dense structure similar to cortical bone without pores; the inner layer is a pore structure with a size of 100-3...

Embodiment 3

[0050] Example 3: Preparation of nano-hydroxyapatite / polycaprolactone artificial bone scaffold with 30% HA transverse gradient pore structure.

[0051] Using liquid nitrogen as a refrigerant, the polycaprolactone particles with a diameter of about 3-5 mm were crushed into particles of 110±20 μm by cryogenic crushing technology for later use. 3 kg of nano-HA powder with a particle size of 40 ± 10 nm was mixed with 7 kg of prepared PCL powder to obtain 10 kg of nano-HA / PCL mixed powder with a mass ratio of HA of 10%. Pour the nano-HA / PCL mixed powder into the container of the V-shaped mixer, and rotate forward (clockwise) and reverse (counterclockwise) for 1 hour each to obtain a uniformly mixed nano-HA / PCL mixed powder. Use 3D graphics design software on the computer to design a 3D model of computer-aided design (COMPUTER AIDED DESIGN, CAD). The outermost layer is a dense structure similar to cortical bone without pores; the inner layer is a pore structure with a size of 100-3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com