Improved structure of wire-cutting machine tool for graphite electrode curved surface projection precision machining

A wire-cutting machine tool and graphite electrode technology, which is applied in stone processing tools, stone processing equipment, and work accessories, can solve the problems of inability to accurately process graphite electrode surface projection, low cost, and low operating cost, and achieve low processing and operating costs , Low equipment cost and low transformation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

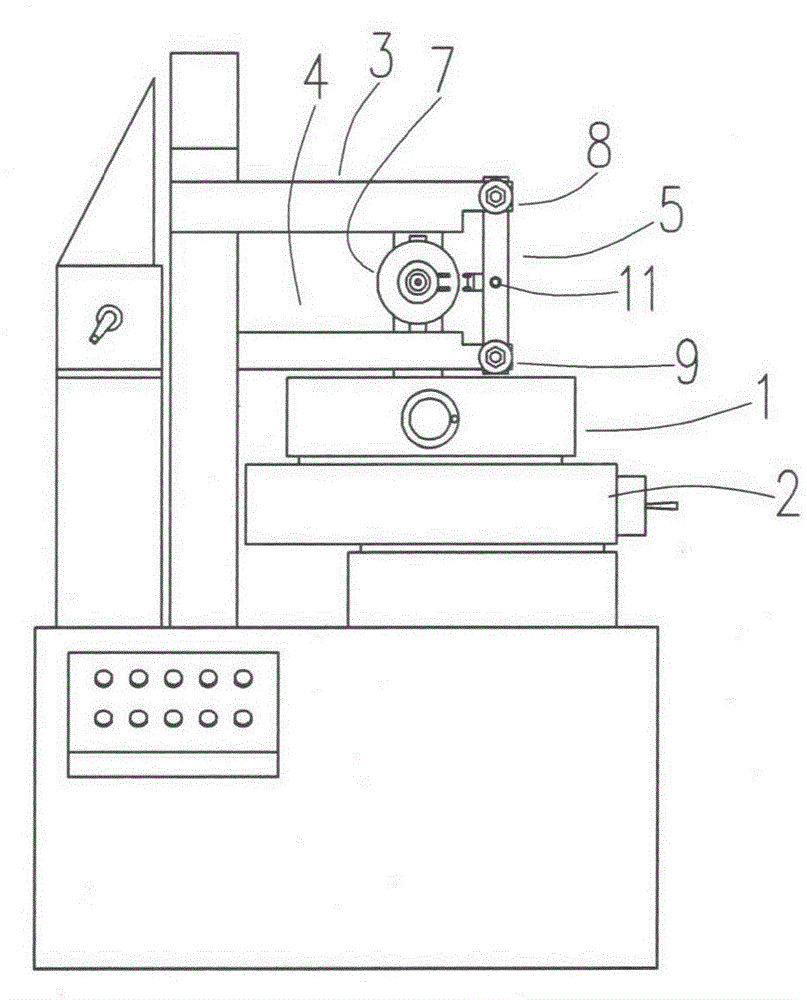

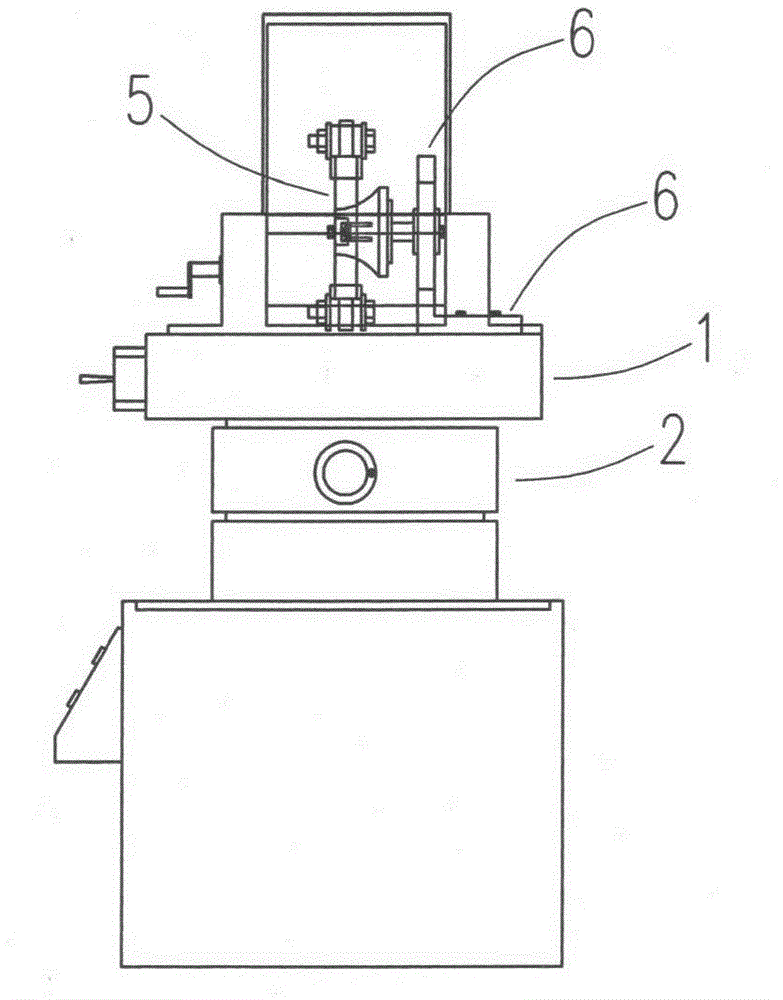

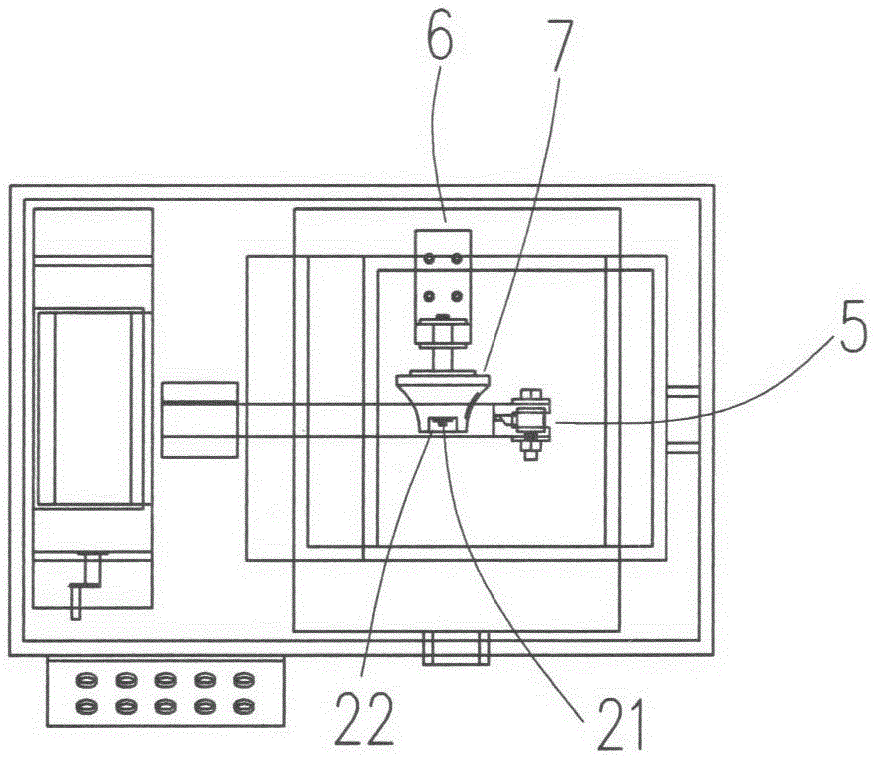

[0016] Such as Figure 1 to Figure 8 As shown, an embodiment of the present invention includes: program input and output equipment, numerical control device, X-axis table 1, Y-axis table 2, upper cantilever 3, lower cantilever 4, and also includes a blade clamp 5 and a graphite electrode clamp 6. Both ends of the blade holder 5 are respectively fixed on the ends of the upper cantilever 3 and the lower cantilever 4 , and the graphite electrode holder 6 is fixed on the X-axis table 1 . Described blade fixture 5 comprises upper connection seat 8 and lower connection seat 9, and blade holder 5 is provided with blade placement groove 10 and matching fastening screw 11, and upper connection seat 8 is fixed on the outer end of upper cantilever 3, and lower connection Seat 9 is fixed on the outer end of lower cantilever 4. Certainly, the blade holder 5 may also have other variable structures, as long as the blade 23 can be fixed on the upper boom 3 and the lower boom 4 . Described g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com