Technique for fluorite mine floatation sewage treatment

A flotation wastewater and treatment process technology, which is applied in the field of fluorite ore flotation wastewater treatment process, can solve the problems of high operating cost of the treatment process, hidden environmental hazards, and poor effluent quality, and achieve low process operating costs and reduced operating costs , the effect of saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

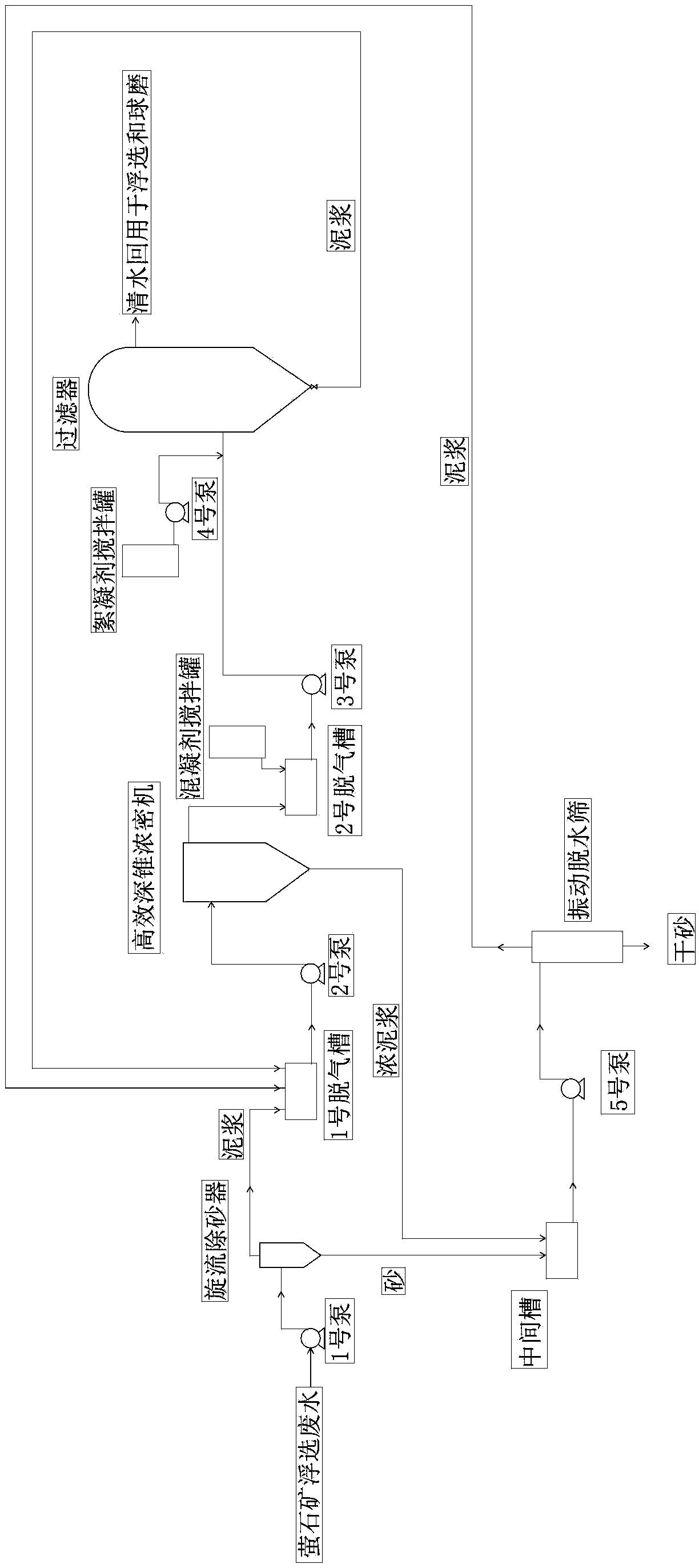

[0035] Such as figure 1 as shown, figure 1 It is a flow chart of the flotation wastewater treatment process for fluorite ore. Taking wastewater from a flotation plant of a fluorite mine in Henan as an example, the implementation of this process is introduced.

[0036]Fluorite ore flotation wastewater (the suspended matter content of fluorite ore flotation wastewater is 42603mg / L) is pumped into the cyclone desander at a flow rate of 40 cubic meters per hour by No. 1 pump to achieve the separation of sand and mud; The mud from the top of the cyclone desander is degassed through the No. 1 degassing tank, and the mud discharged from the vibrating dewatering screen and filter enters the No. 1 degassing tank for degassing, and then pumped into the high-efficiency deep cone thickener through the No. 2 pump. The thin mud (solid content is 1%) from the upper part is degassed through No. 2 degassing tank, and at the same time, 100 liters of ferrous sulfate solution with a concentrati...

Embodiment 2

[0039] Fluorite ore flotation wastewater (the suspended matter content of fluorite ore flotation wastewater is 50210mg / L) is pumped into the cyclone desander at a flow rate of 40 cubic meters per hour by No. 1 pump to achieve the separation of sand and mud; The mud from the top of the cyclone desander is degassed through the No. 1 degassing tank, and the mud discharged from the vibrating dewatering screen and filter enters the No. 1 degassing tank for degassing, and then pumped into the high-efficiency deep cone thickener through the No. 2 pump. The thin mud (solid content is 0.8%) from the upper part is degassed through No. 2 degassing tank, and at the same time, 100 liters of ferrous sulfate solution with a concentration of 1% dissolved in the coagulant stirring tank is added every hour, and passed through No. 3 After the pump is pumped into the filter, 300 liters of anionic polyacrylamide solution with a molecular weight of 10 million and a concentration of 0.2% are added to...

Embodiment 3

[0042] Fluorite ore flotation wastewater (the suspended matter content of fluorite ore flotation wastewater is 47508mg / L) is pumped into the cyclone desander at a flow rate of 40 cubic meters per hour by No. 1 pump to achieve the separation of sand and mud; The mud from the top of the cyclone desander is degassed through the No. 1 degassing tank, and the mud discharged from the vibrating dewatering screen and filter enters the No. 1 degassing tank for degassing, and then pumped into the high-efficiency deep cone thickener through the No. 2 pump. The thin mud (solid content is 6%) from the upper part is degassed through No. 2 degassing tank, and at the same time, 100 liters of ferrous sulfate solution with a concentration of 3% dissolved in the coagulant stirring tank is added every hour, and passed through No. 3 After the pump is pumped into the filter, 300 liters of anionic polyacrylamide solution with a molecular weight of 10 million and a concentration of 0.15% dissolved in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com