Pd/MIL-53(Al) catalyst, preparation and application thereof

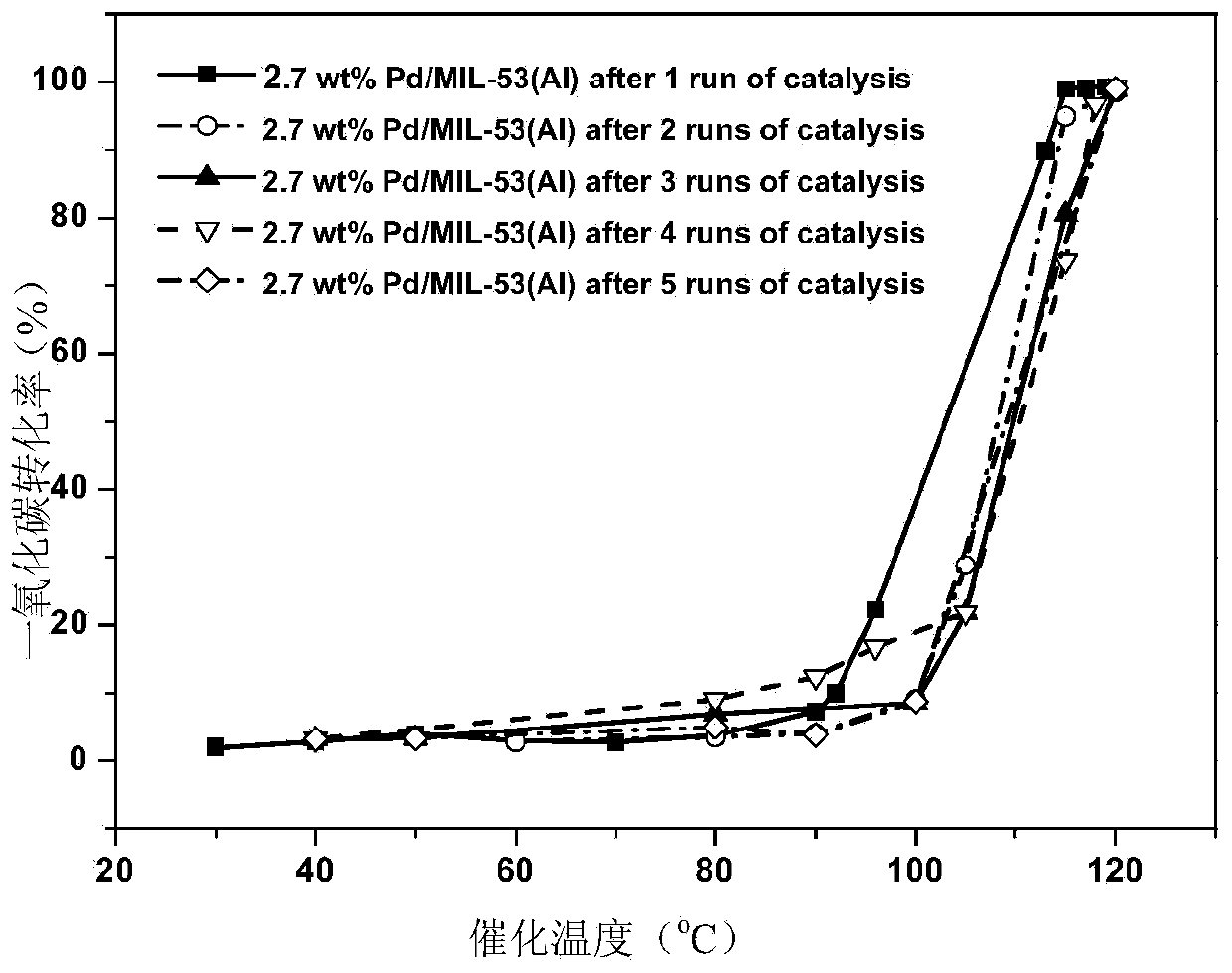

A catalyst and reaction kettle technology, applied in the field of Pd/MIL-53 catalyst and its preparation, can solve the problems of many influencing factors, complex process flow, limited industrial production and application, etc. The effect of temperature on the complete catalytic conversion of CO

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The evaluation method of embodiment 1 catalyst activity

[0028] The catalytic activity of the catalyst synthesized by the present invention to the CO oxidation reaction in the FCC regeneration flue gas was evaluated by using an atmospheric fixed bed microreactor laboratory evaluation device. The reactor adopts a quartz tube with an inner diameter of 6mm, and the automatic temperature controller controls the programmed temperature rise reaction, and the temperature rise rate is 5°C / min. Weigh 100mg of the catalyst, fill it in the constant temperature section of the reaction tube, prepare the reaction gas in advance according to the requirements, the gas composition is: CO: 1v%, O 2 : 21v%, Ar is the balance gas; the gas flow rate is 50ml / min. The experimental results were detected by the SP-3420 gas chromatograph produced by Beijing Analytical Instrument Factory. The FID hydrogen flame ion detector, the FID and the methane converter are connected in series, and the chr...

Embodiment 2

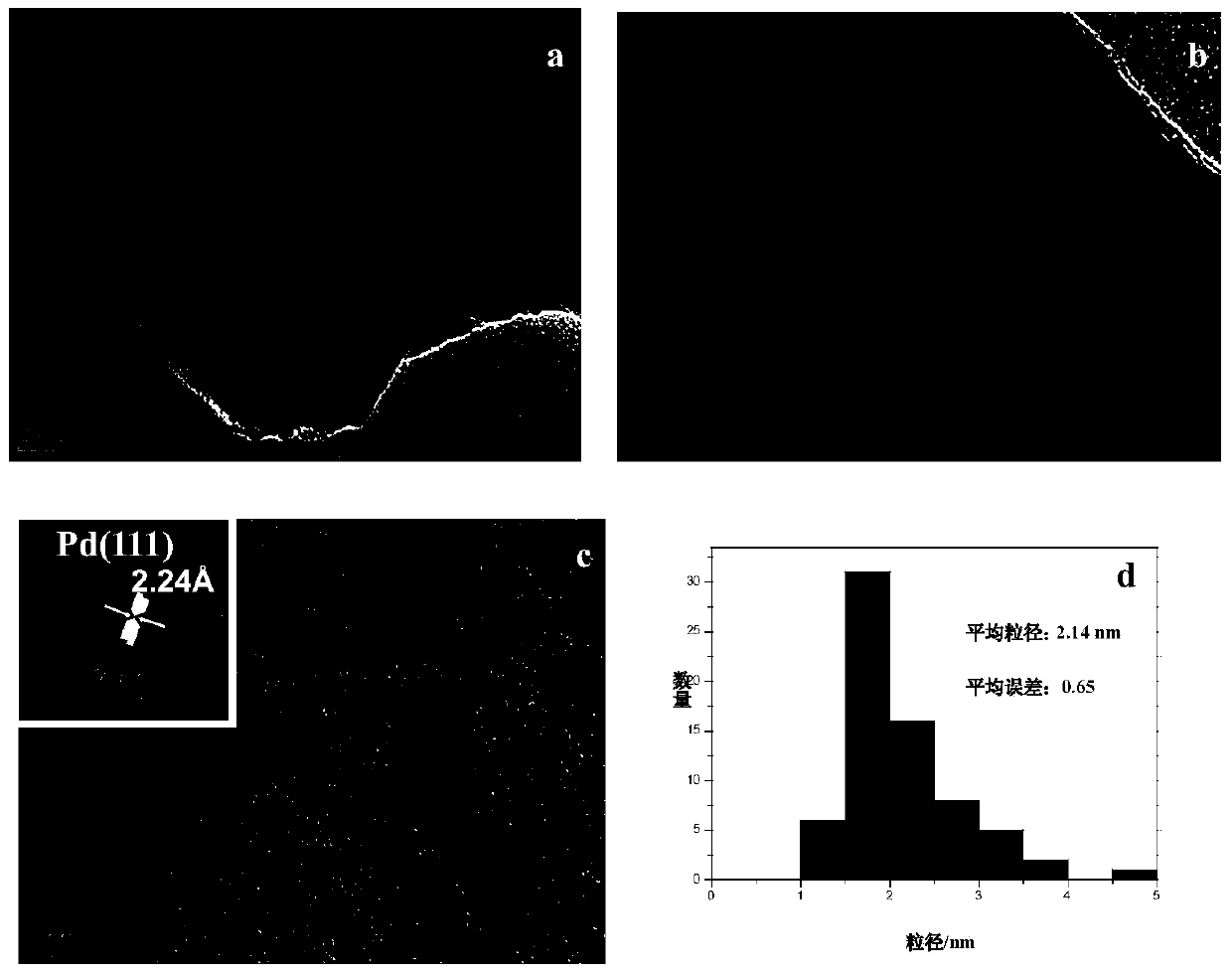

[0029] The preparation method of embodiment 2Pd / MIL-53 (Al)

[0030] Weigh H separately 2 BDC (2.88g), Al (NO 3 ) 3 9H 2 O (14.5g) was put into a 100mL reaction kettle, deionized water (65mL) was added, and stirred for 30 minutes. The reaction kettle was sealed and placed in an oven, and reacted at a constant temperature of 220°C for 72 hours, with a heating rate of 1°C per minute. Cool naturally to room temperature, filter with deionized water, and dry at 50°C for 12 hours to obtain MIL-53(Al). MIL-53(Al) was calcined at 330°C for 72 hours to remove water molecules and excess ligands in the framework, and palladium nitrate (0.5g) was added to obtain a mixed solution by equal volume impregnation, and dried at 50 for 12 hours. Pass Ar / H at 250°C 2 (0.1L / min) Reductive activation of Pd / MIL-53(Al), the heating rate is 3°C per minute.

[0031] activity evaluation

[0032] Pd / MIL-53 (Pd) is evaluated according to the evaluation method of above-mentioned catalyst activity, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com