Coal Drying Induced by Cold Plasma

A plasma and low-temperature plasma technology, which is applied in coal drying, dehydration drying, and lignite drying, can solve the problems of complex equipment, insufficient lignite dehydration, and high energy consumption, and achieve fast drying speed, easy operation, and high dehydration rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

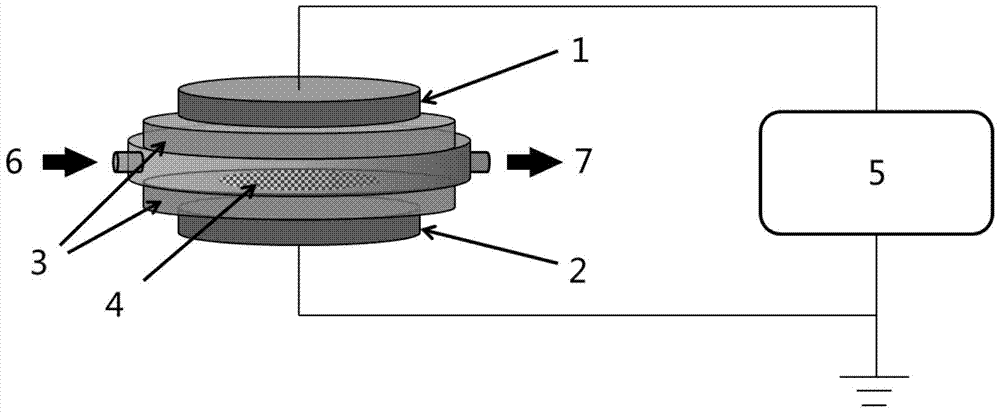

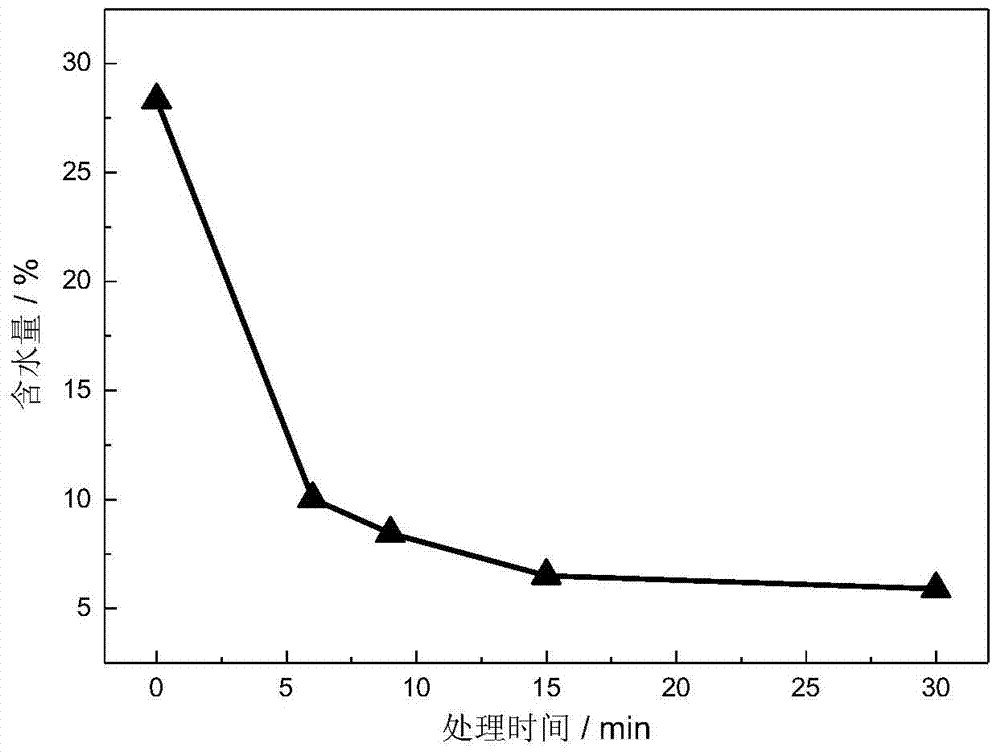

[0028] Grind lignite into coal powder with a fineness of more than 200 meshes, and then add the coal powder into the flat dielectric barrier discharge reaction chamber, such as figure 1 shown. Argon gas was introduced into the reaction chamber to isolate the air, and the flow rate of argon gas was 50 mL / min. A 7000V alternating current was applied between the two electrodes by a high-voltage power supply, and the current frequency was 8kHz. The processing time is 6min, 9min, 15min, 30min etc.

[0029] After the treatment process, the water content of lignite samples with different treatment time was analyzed, as shown in figure 2 shown. With the increase of processing time, the moisture in the lignite is gradually removed, and the moisture content of the lignite sample with a moisture content of about 25% is about 5% after 30 minutes of plasma drying.

Embodiment 2

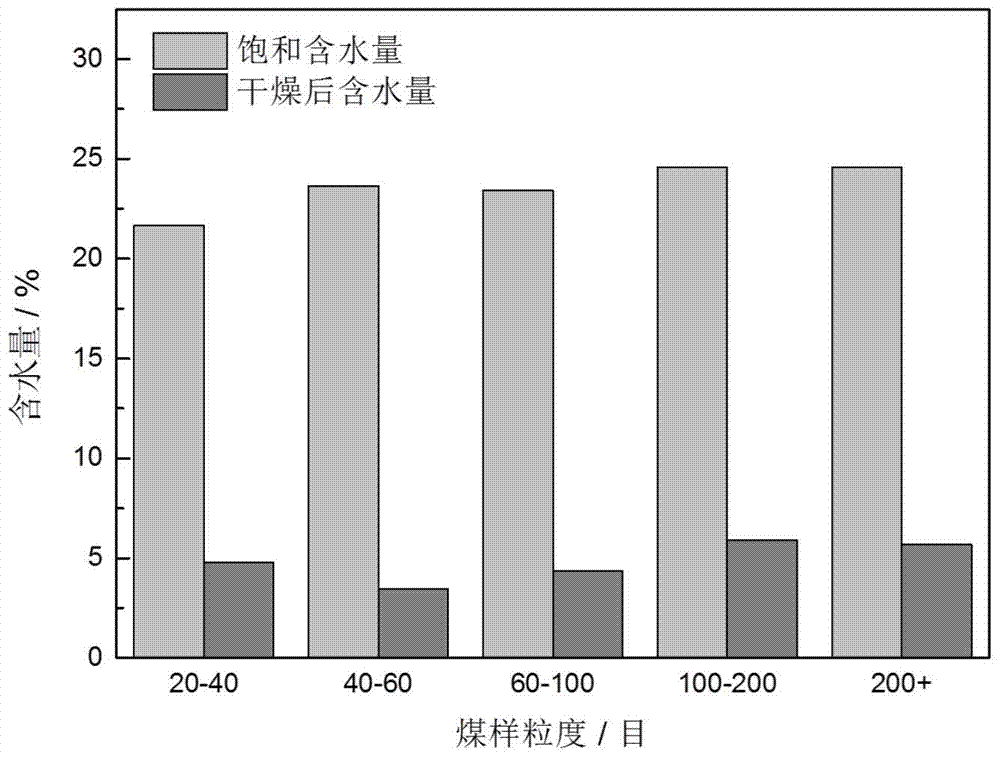

[0031] The lignite is ground into pulverized coal with a fineness of 20 mesh, 40 mesh, 60 mesh, 100 mesh and 200 mesh respectively, and then the pulverized coal is added into the flat dielectric barrier discharge reaction chamber. Argon gas was introduced into the reaction chamber to isolate the air, and the flow rate of argon gas was 10 mL / min. A 7000V alternating current was applied between the two electrodes by a high-voltage power supply, and the current frequency was 8kHz. The processing time is 30min.

[0032] After the treatment process, the water content of the lignite samples with different particle sizes was analyzed, such as image 3 shown. It can be seen that this method has a good dehydration effect for lignite samples of different particle sizes.

Embodiment 3

[0034] Grind the gas coal into 200-mesh coal powder and add it to the flat dielectric barrier discharge reaction chamber. Helium was introduced into the reaction chamber to isolate the air, and the flow rate of helium was 10mL / min. A high-voltage power supply is used to apply 20000V alternating current between the two electrodes, and the current frequency is 8kHz. The processing time is 5 minutes.

[0035] After the treatment process, it was found that the plasma treatment process had a good dehydration effect on the gas-coal sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com