Washboard type roller washing method and washing machine applying the same method

A drum washing machine and drum technology, which is applied to washing machines with containers, other washing machines, washing machine appliances, etc., can solve the problems of low washing ratio, unsatisfactory washing effect of drum washing machines, etc., achieve high dehydration rate, improve strength and rigidity , the effect of improving life expectancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

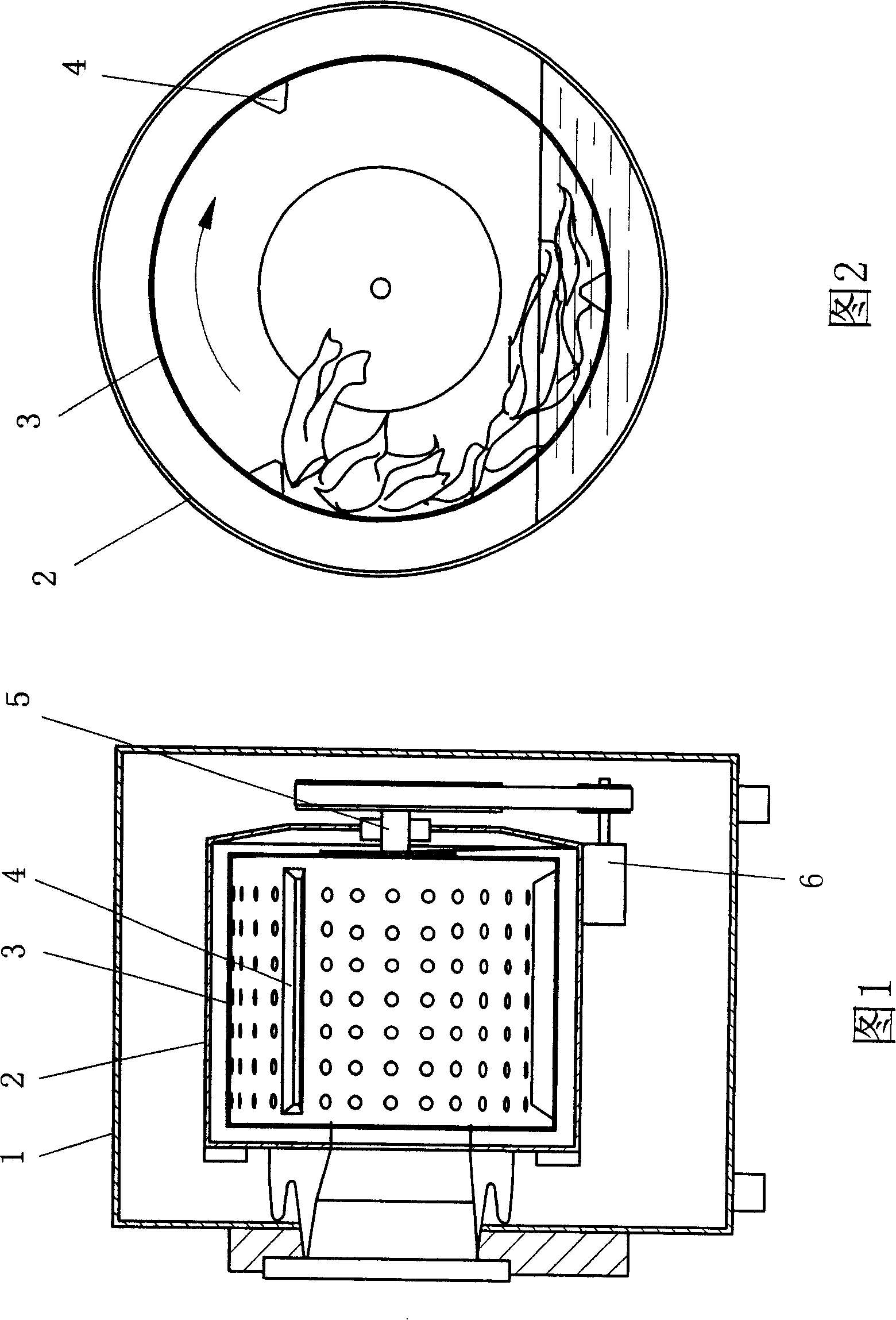

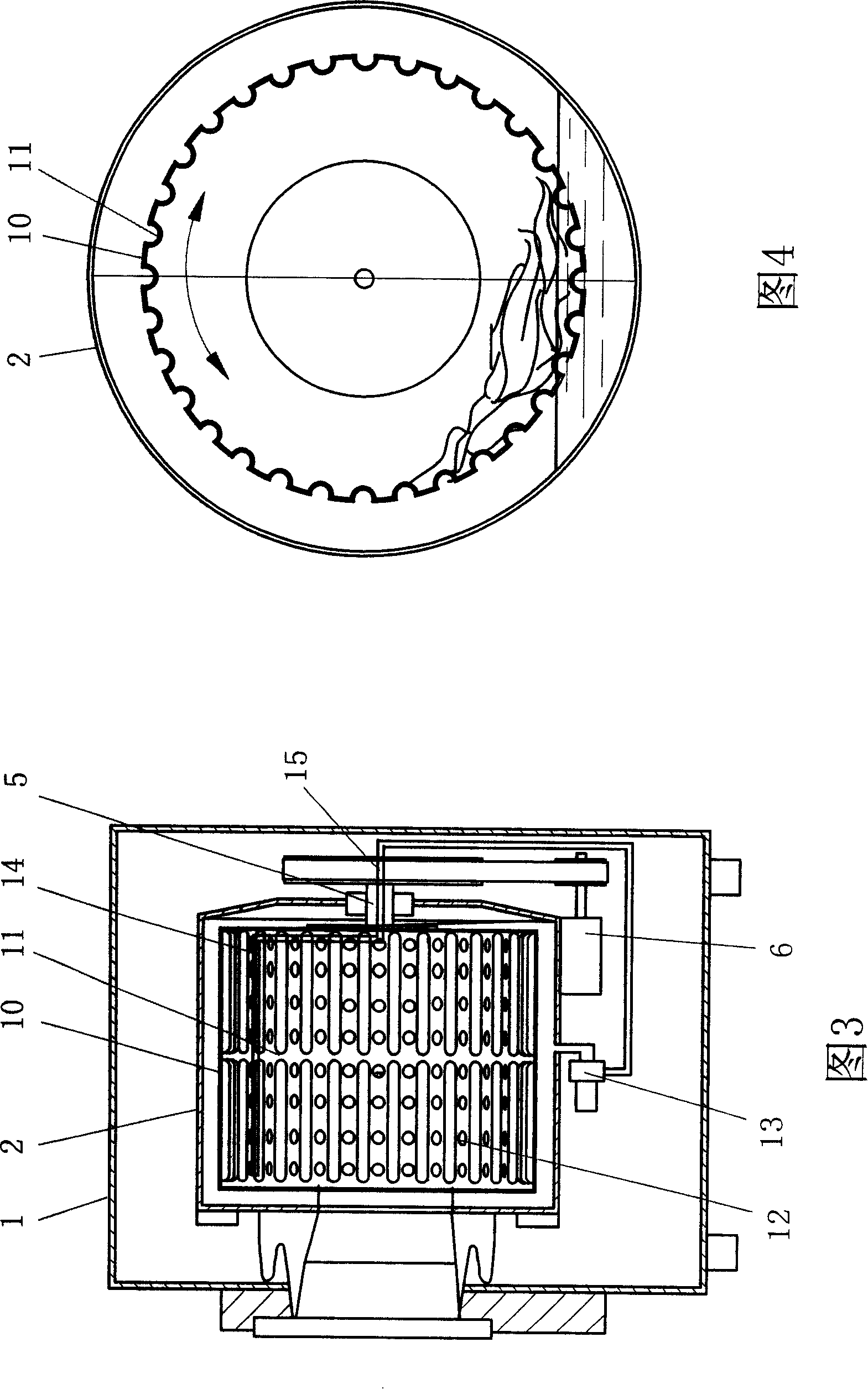

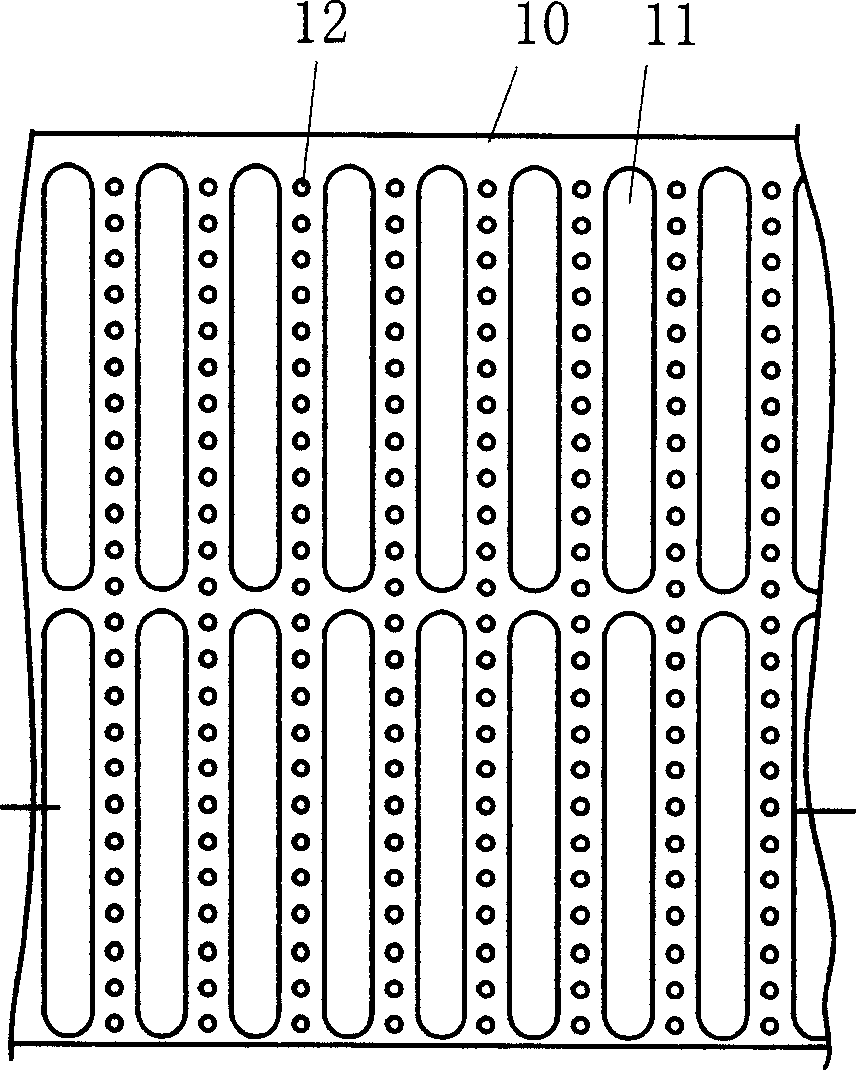

[0039] The invention provides a novel washboard type drum washing method, which is suitable for a washboard type drum washing machine. In the washboard type drum washing machine, a plurality of axial convex ribs are densely arranged on the inner wall of the drum. Its procedure steps are as Figure 11 As shown, it includes programs such as soaking, washing, dehydration, rinsing, and dehydration. The difference from the existing drum washing machine is that the washing program is different. The washing program of the present invention includes the following steps:

[0040] Step 1. Add water and detergent or washing powder to make the washing liquid soak into the laundry. The water level is lower than that of the existing drum washing machine, and soak for 15 to 30 minutes.

[0041] Step 2. The drum rotates back and forth multiple times at the first low speed; the laundry is rubbed and tumbled by using densely packed axial ribs; the first speed is lower than the rotation speed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com