Method for treating sludge by use of polyaluminum chloride and ultrasonic combining technology

A technology of polyaluminum chloride and combined use technology, which is applied in the field of sludge treatment with polyaluminum chloride and ultrasonic combined use technology, can solve the problem of weak improvement of sludge performance, secondary pollution, and incomplete solution of bound water. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

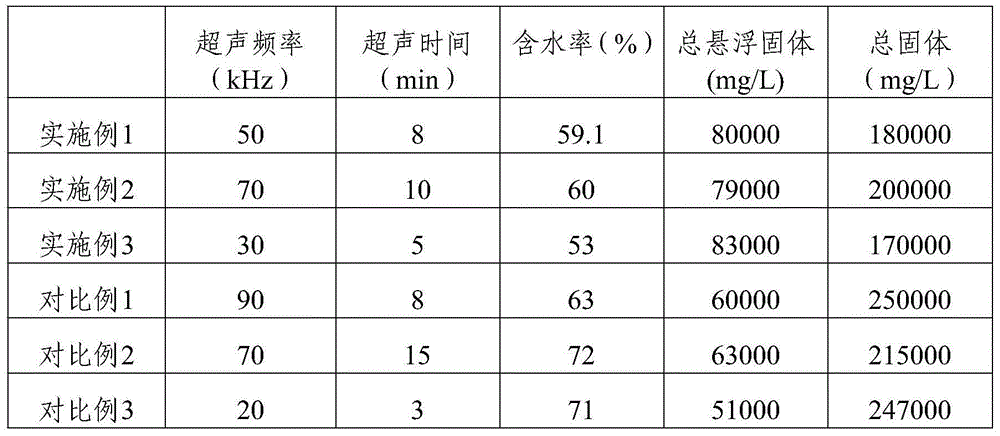

Embodiment 1

[0016] A kind of polyaluminum chloride and the method for ultrasonic combination technique to sludge treatment, comprise the following steps:

[0017] (1) The pH of the sludge is adjusted with the adjusting solution so that the pH value of the sludge is 9.3, and then the sludge is placed in the stirring tank, and the stirring speed is 1800r / min. Add 400 mg of polyaluminum chloride, and stir at a constant speed for 20 minutes;

[0018] (2) Stop stirring the sludge after the stirring reaction in step (1), let it stand for 20 minutes, then send it to an ultrasonic processor, adjust the temperature to 20°C for 8 minutes, and then send it to a centrifugal dehydrator The centrifugal dehydration treatment in the middle can improve the dewatering performance of the sludge.

[0019] The regulating solution is sodium hydroxide solution with a concentration of 0.7mol / L.

[0020] In the ultrasonic processor, the frequency of the ultrasonic wave is 50kHz.

[0021] Described centrifugal ...

Embodiment 2

[0023] A kind of polyaluminum chloride and the method for ultrasonic combination technique to sludge treatment, comprise the following steps:

[0024] (1) The pH of the sludge is adjusted with the adjusting solution so that the pH value of the sludge is 11, and then the sludge is placed in the stirring tank, and the stirring speed is 2000r / min. Add 500 mg of polyaluminum chloride, and stir at a constant speed for 30 minutes;

[0025] (2) Stop stirring the sludge after the stirring reaction in step (1), let it stand for 30 minutes, then send it to an ultrasonic processor, adjust the temperature to 25°C for 10 minutes, and then send it to a centrifugal dehydrator The centrifugal dehydration treatment in the middle can improve the dewatering performance of the sludge. The regulating solution is sodium hydroxide solution with a concentration of 1mol / L.

[0026] In the ultrasonic processor, the frequency of the ultrasonic wave is 70kHz.

[0027] Described centrifugal dehydrator,...

Embodiment 3

[0029] A kind of polyaluminum chloride and the method for ultrasonic combination technique to sludge treatment, comprise the following steps:

[0030] (1) The pH of the sludge is adjusted with the adjusting solution so that the pH value of the sludge is 8, and then the sludge is placed in the stirring tank, and the stirring speed is 1500r / min. Add 300mg of polyaluminum chloride, and stir at a constant speed for 15 minutes;

[0031] (2) Stop stirring the sludge after the stirring reaction in step (1), let it stand for 15 minutes, then send it to an ultrasonic processor, adjust the temperature to 15°C for 5 minutes, and then send it to a centrifugal dehydrator The centrifugal dehydration treatment in the middle can improve the dewatering performance of the sludge. The regulating solution is sodium hydroxide solution with a concentration of 0.1mol / L.

[0032] In the ultrasonic processor, the frequency of the ultrasonic wave is 30kHz.

[0033] Described centrifugal dehydrator, it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dryness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com