5 series aluminium alloy plate production method

A technology of aluminum alloy plate and production method, which is applied in the field of metal materials, can solve the problems of lack of systematicness, use requirements, and inability to fully meet the hull materials, etc., and achieve internal structure improvement, good corrosion resistance and mechanical properties, and elimination of tissue and The effect of uneven composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1.1 The 5083 aluminum alloy ingot with a magnesium element mass fraction of 4.1% is subjected to homogenization heat treatment at a soaking temperature of 460°C, and then starts cooling after 15 hours. After cooling to 280°C, the homogenized heat-treated aluminum alloy is obtained. alloy ingot.

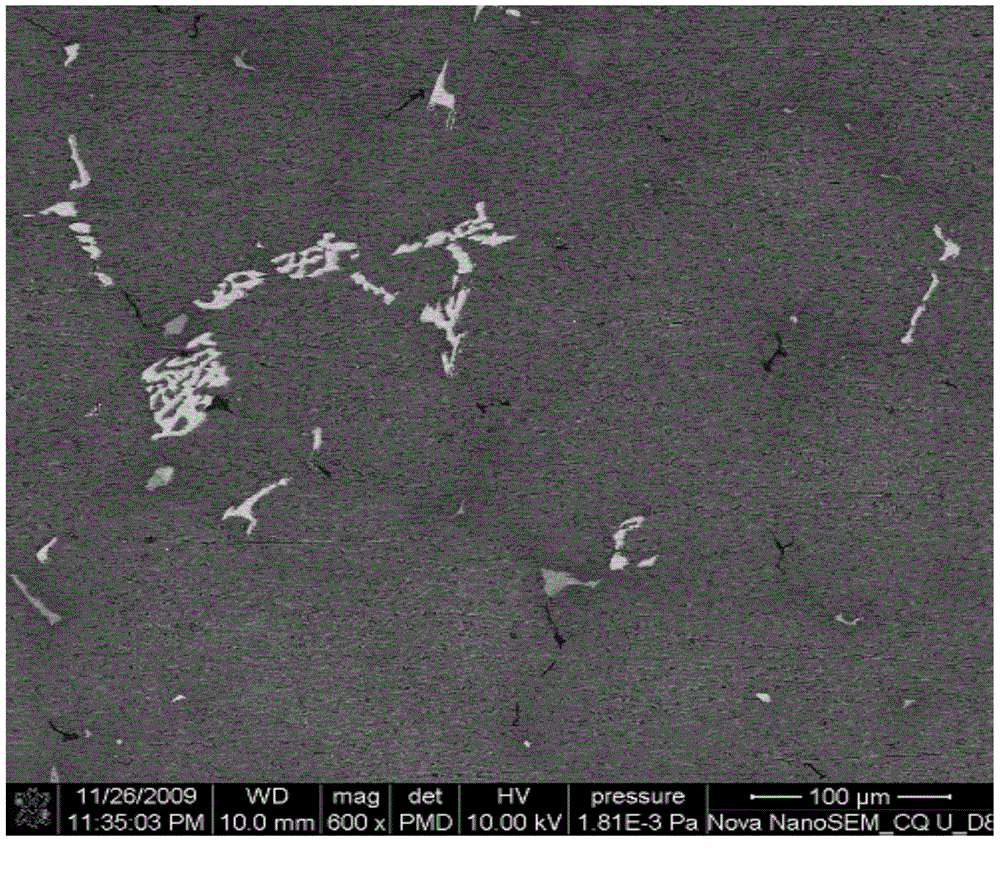

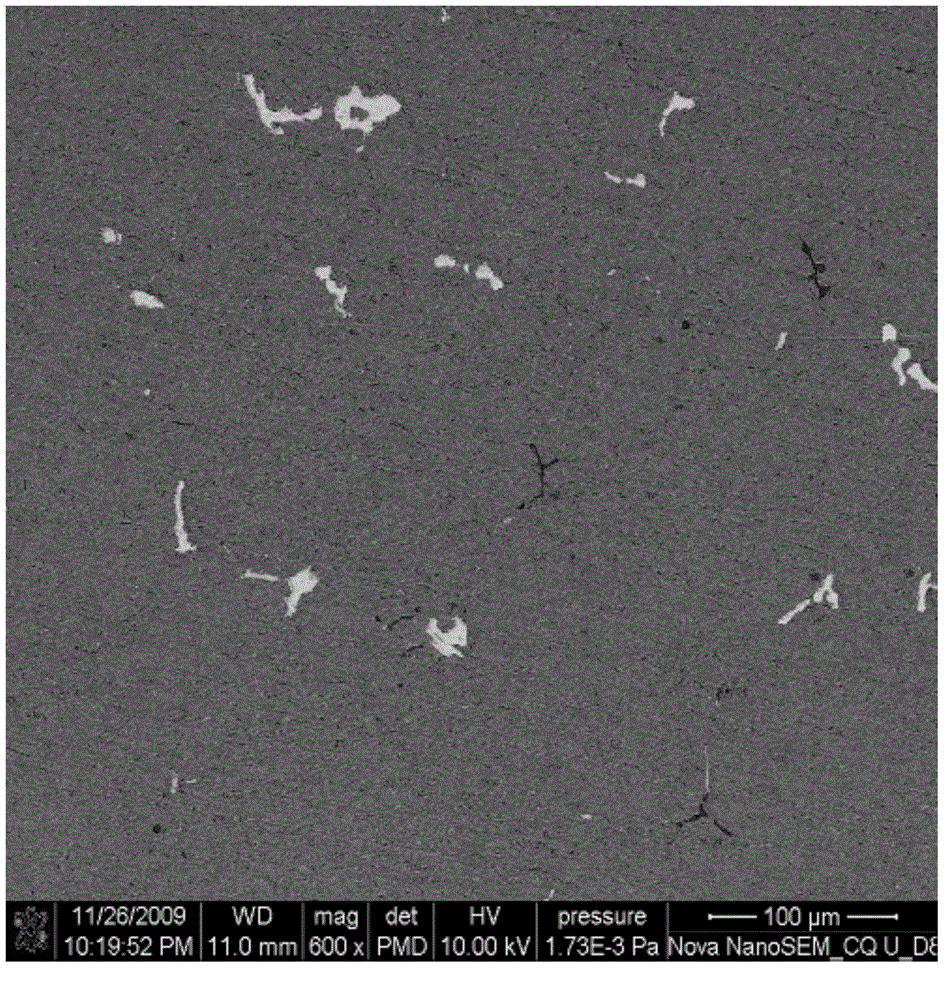

[0036] see figure 1 and figure 2 , figure 1 It is a metallographic photograph of an aluminum alloy ingot in Example 1 of the present invention; figure 2 It is the metallographic photograph of the aluminum alloy ingot after the homogenization heat treatment in Example 1 of the present invention, by figure 1 and figure 2 It can be seen that the aluminum alloy ingot after the homogenization heat treatment of the present invention, the area percentage of the second phase after the homogenization treatment is significantly reduced, the homogenization heat treatment process controls the second phase better, and no intergranular loose defects are seen. In the high-magnificatio...

Embodiment 2

[0042] 1.1 The 5083 aluminum alloy ingot with a magnesium element mass fraction of 4.4% is subjected to homogenization heat treatment at a soaking temperature of 510°C, and then starts cooling after 17 hours. After cooling to 300°C, the homogenized heat-treated aluminum alloy is obtained. alloy ingot.

[0043] 1.2 Heat the homogenized aluminum alloy ingot obtained in 1.1 to 460° C. to obtain a heated aluminum alloy ingot.

[0044] 1.3 The heated aluminum alloy ingot obtained in 1.2 is hot-rolled at a temperature of 300° C. with 60% deformation reserved by a large deformation rolling process to obtain an intermediate aluminum alloy plate.

[0045] 1.4 The intermediate aluminum alloy plate obtained in 1.3 is subjected to a second hot rolling at 270° C. to obtain an aluminum alloy plate with a thickness of 16.0 mm.

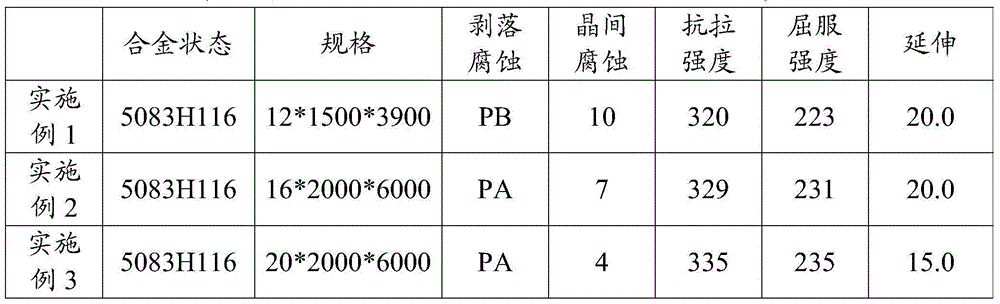

[0046] According to GB / T22641-2008, the aluminum alloy plate obtained in 1.4 is tested, and the test results are shown in Table 1. Table 1 shows the performance par...

Embodiment 3

[0048] 1.1 The 5083 aluminum alloy ingot with a magnesium element mass fraction of 4.9% is subjected to homogenization heat treatment at a soaking temperature of 560°C, and then starts to cool after 20 hours. After cooling to 300°C, the homogenized heat-treated aluminum alloy is obtained. alloy ingot.

[0049] 1.2 Heat the homogenized aluminum alloy ingot obtained in 1.1 to 470° C. to obtain a heated aluminum alloy ingot.

[0050] 1.3 The heated aluminum alloy ingot obtained in 1.2 is hot-rolled at a temperature of 330° C. with 70% deformation reserved by a large deformation rolling process to obtain an intermediate aluminum alloy plate.

[0051] 1.4 The intermediate aluminum alloy plate obtained in 1.3 is subjected to a second hot rolling at 280° C. to obtain an aluminum alloy plate with a thickness of 20.0 mm.

[0052] According to GB / T22641-2008, the aluminum alloy plate obtained in 1.4 is tested, and the test results are shown in Table 1. Table 1 shows the performance par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com