EPE material for crawling pad, preparation method of EPE material and crawling pad

A technology of crawling mat and mixing machine, applied in the field of crawling mat, can solve the problems of poor resilience and low surface water absorption, and achieve the effects of excellent shock absorption performance, low surface water absorption and excellent thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

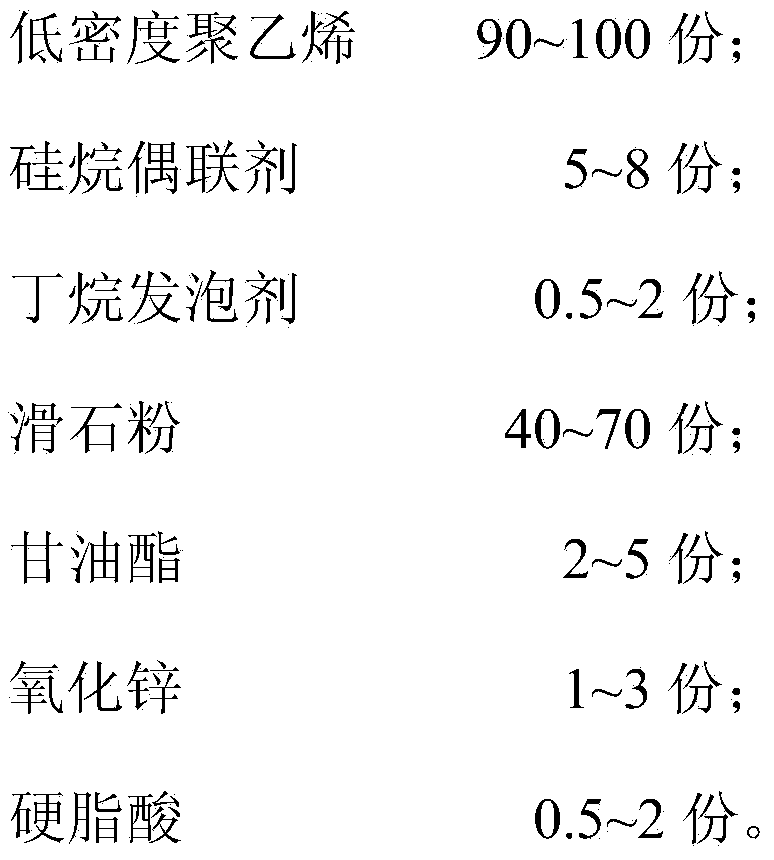

[0032] Embodiment 1: The EPE material for the crawling mat of this embodiment, in parts by mass, includes the following components:

[0033]

[0034] The method for preparing the above-mentioned crawling mat EPE material, it may further comprise the steps:

[0035] In terms of parts by mass, put 40 parts of talc powder and 1 part of zinc oxide into the mixer, and stir at 85°C for 6 minutes; add 5 parts of silane coupling agent and 90 parts of low-density polyethylene and raise the temperature to 110°C and continue stirring for 6 minutes Add 2 parts of glyceride and 0.5 part of stearic acid and continue to stir for 2 minutes, and put it into the extruder and add 0.5 part of butane foaming agent to carry out mixing, foaming, extrusion molding, cooling, traction, flattening and foaming Sheet, made of crawling mat EPE material.

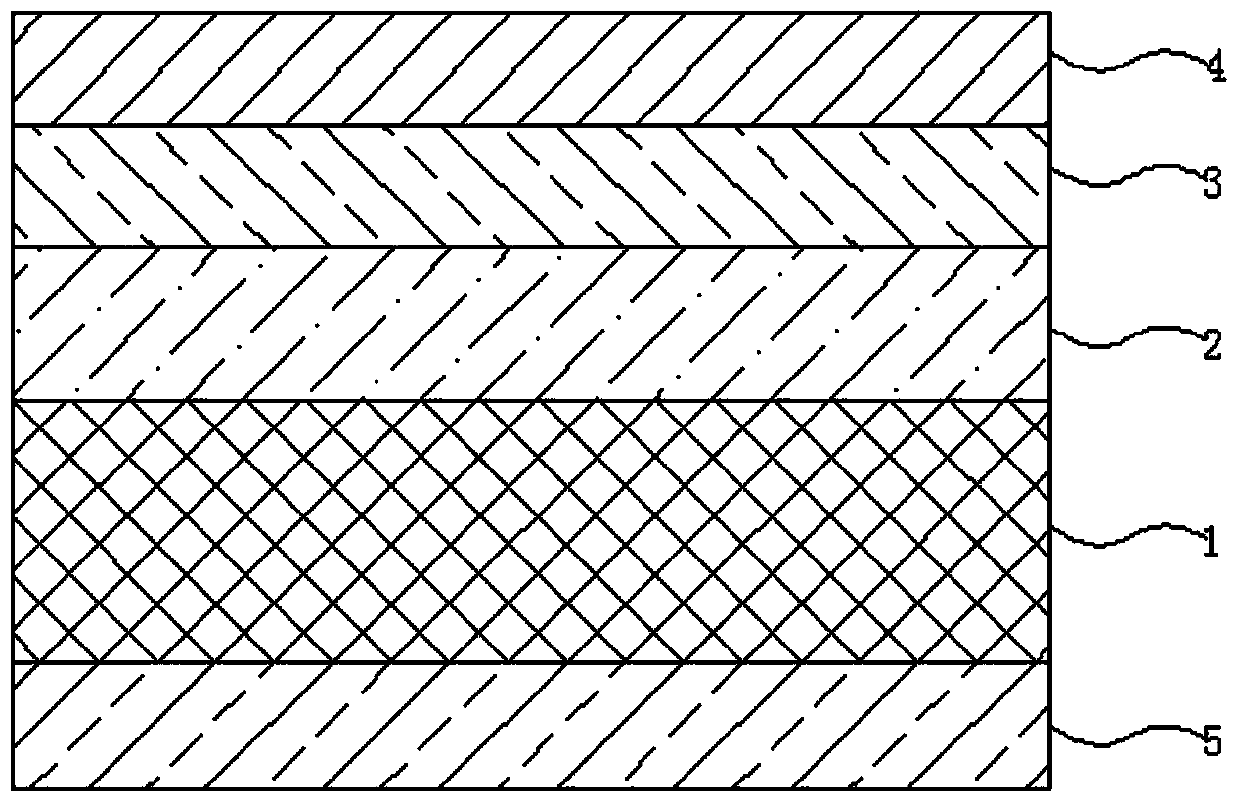

[0036] The crawling mat of the present embodiment comprises an EPE layer 1 made of the above-mentioned EPE material for the crawling mat, and one sid...

Embodiment 2

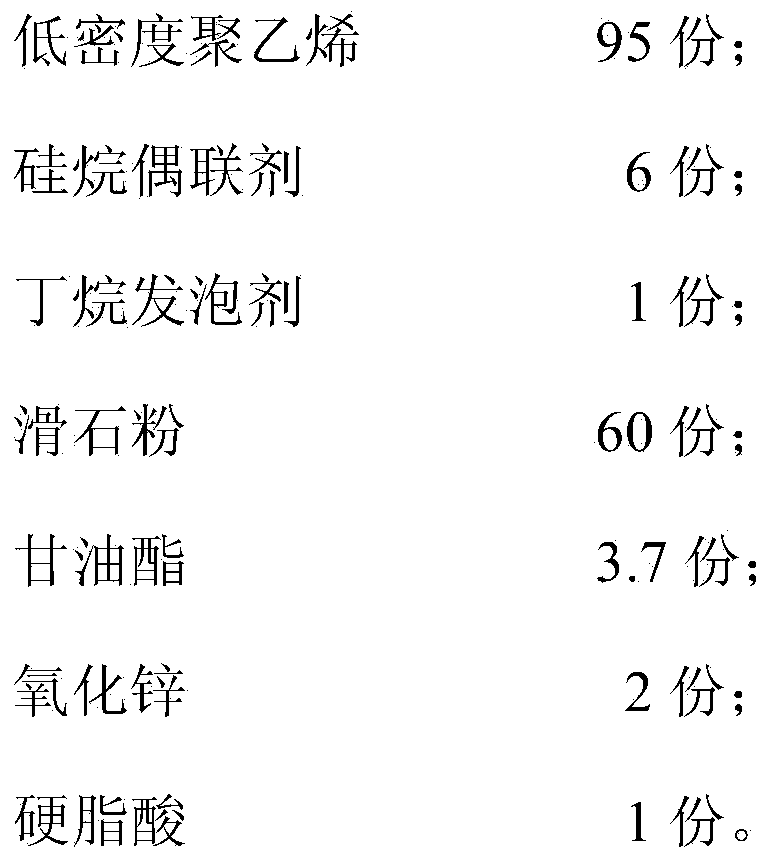

[0038] Embodiment 2: The EPE material for the crawling mat of this embodiment, in parts by mass, includes the following components:

[0039]

[0040] The method for preparing the above-mentioned crawling mat EPE material, it may further comprise the steps:

[0041] In terms of parts by mass, put 60 parts of talc powder and 2 parts of zinc oxide into the mixer, and stir at 90°C for 7 minutes; add 6 parts of silane coupling agent and 95 parts of low-density polyethylene and raise the temperature to 110°C and continue stirring for 7 minutes Add 4 parts of glyceride and 1 part of stearic acid and continue to stir for 2.5 minutes, and put it into the extruder and add 1 part of butane foaming agent to carry out mixing, foaming, extrusion molding, cooling, traction, and flattening. Foam sheet, made crawling mat EPE material.

[0042] The crawling mat of the present embodiment comprises an EPE layer 1 made of the above-mentioned EPE material for the crawling mat, and one side of t...

Embodiment 3

[0044] Embodiment 3: The EPE material for the crawling mat of this embodiment, in parts by mass, includes the following components:

[0045]

[0046] The method for preparing the above-mentioned crawling mat EPE material, it may further comprise the steps:

[0047] In terms of parts by mass, put 70 parts of talc powder and 3 parts of zinc oxide into the mixer, and stir at 90°C for 8 minutes; then add 8 parts of silane coupling agent and 100 parts of low-density polyethylene and heat up to 115°C to continue stirring 7min; Finally, add 5 parts of glyceride and 2 parts of stearic acid and continue to stir for 3 minutes, and put it into the extruder, add 2 parts of butane foaming agent for kneading, foaming, extrusion molding, cooling, traction, and flattening Foam sheet, made crawling mat EPE material.

[0048] The crawling mat of the present embodiment comprises an EPE layer 1 made of the above-mentioned EPE material for the crawling mat, and one side of the EPE layer 1 is seq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com