Styrofoam plastic with antibacterial and antifungal functions

A foam, antibacterial and anti-mold technology, applied in the field of foam plastics, can solve the problems of difficulty in ensuring the effectiveness of nano-components and the inability to inhibit the self-aggregation of nano-particles, and achieve durable and stable anti-bacterial and anti-mold, fewer steps, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

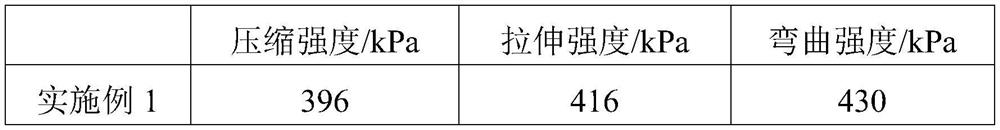

Examples

Embodiment 1

[0055] The preparation method of the foamed plastic with antibacterial and antifungal function is as follows:

[0056] (1) In parts by weight, mix 60 parts of polyol composition and 1 part of compound antibacterial agent at 25°C and 50% relative humidity; add 60 parts of polyisocyanate, stir at 600rpm for 25s, inject The mold that has been preheated to 80°C is foamed at 80°C for 5 minutes to obtain molded foam plastics;

[0057] (2) Put the molded foam together with the mold in an oven at 90°C for 3 hours, then cool it down to room temperature naturally, peel it off from the mold, and you get the product.

[0058] The polyisocyanate is toluene diisocyanate (TDI).

[0059] The polyol composition is calculated in parts by weight: 100 parts of polyol, 4 parts of plasticizer, 5 parts of catalyst, 8 parts of foaming agent, and 4 parts of foam stabilizer.

[0060] The polyol is a mixture of 64 parts by weight of polyether polyol 303 and 36 parts by weight of polyether polyol 204 ....

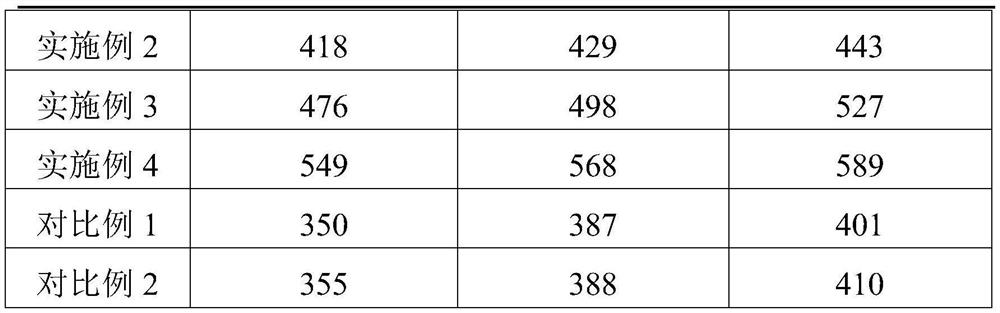

Embodiment 2

[0070] The preparation method of the foamed plastic with antibacterial and antifungal function is as follows:

[0071] (1) In parts by weight, mix 60 parts of polyol composition and 1 part of compound antibacterial agent at 25°C and 50% relative humidity; add 60 parts of polyisocyanate, stir at 600rpm for 25s, inject The mold that has been preheated to 80°C is foamed at 80°C for 5 minutes to obtain molded foam plastics;

[0072] (2) Put the molded foam together with the mold in an oven at 90°C for 3 hours, then cool it down to room temperature naturally, peel it off from the mold, and you get the product.

[0073] The polyisocyanate is toluene diisocyanate (TDI).

[0074] The polyol composition is calculated in parts by weight: 100 parts of polyol, 4 parts of plasticizer, 5 parts of catalyst, 8 parts of foaming agent, and 4 parts of foam stabilizer.

[0075] The polyol is a mixture of 64 parts by weight of polyether polyol 303 and 36 parts by weight of polyether polyol 204 ....

Embodiment 3

[0085] The preparation method of the foamed plastic with antibacterial and antifungal function is as follows:

[0086] (1) In parts by weight, mix 60 parts of polyol composition and 1 part of compound antibacterial agent at 25°C and 50% relative humidity; add 60 parts of polyisocyanate, stir at 600rpm for 25s, inject The mold that has been preheated to 80°C is foamed at 80°C for 5 minutes to obtain molded foam plastics;

[0087] (2) Put the molded foam together with the mold in an oven at 90°C for 3 hours, then cool it down to room temperature naturally, peel it off from the mold, and you get the product.

[0088] The polyisocyanate is toluene diisocyanate (TDI).

[0089] The polyol composition is calculated in parts by weight: 100 parts of polyol, 4 parts of plasticizer, 5 parts of catalyst, 8 parts of foaming agent, and 4 parts of foam stabilizer.

[0090] The polyol is a mixture of 64 parts by weight of polyether polyol 303 and 36 parts by weight of polyether polyol 204 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com