Method for preparing graphene microsphere through normal-pressure drying

A technology of atmospheric drying and graphene, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, to achieve the effect of low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

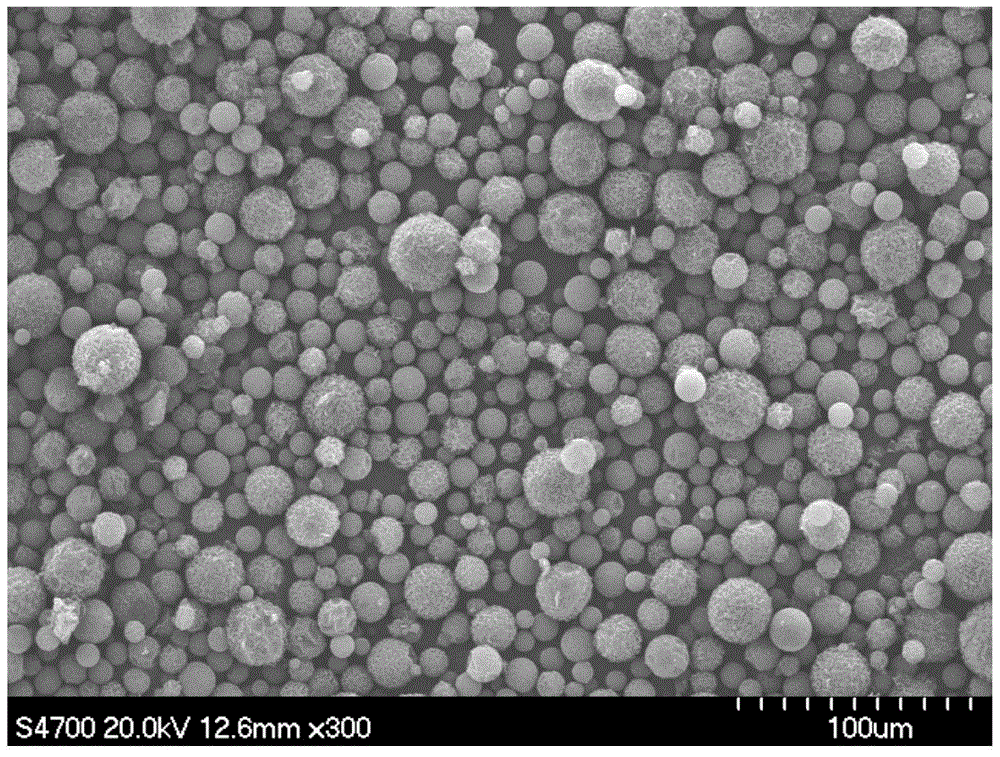

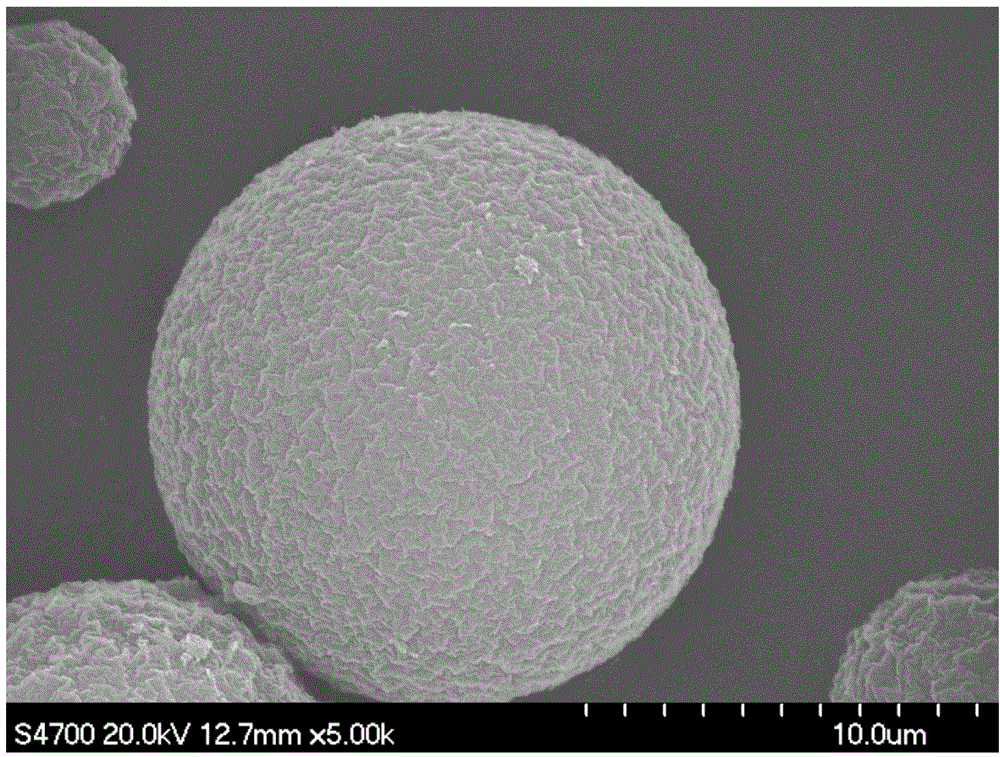

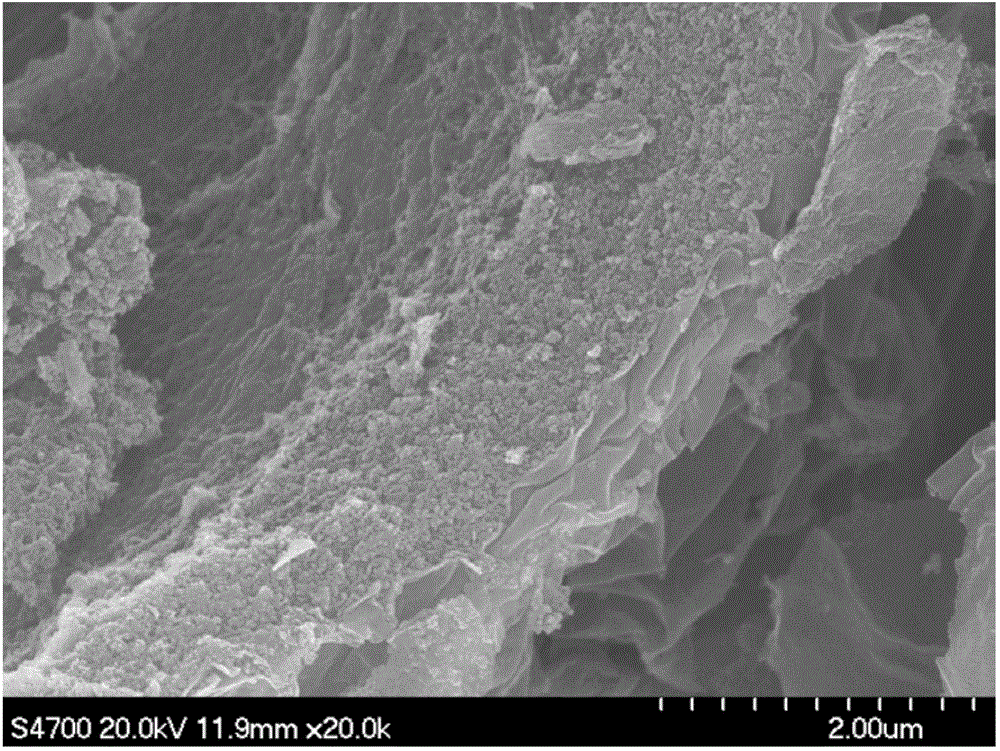

[0031] Embodiment 1: with m-cresol (P), benzaldehyde (F), potassium hydroxide (C) according to the ratio of molar ratio P:F=1:3, P:C=20, be made into solid content and be 4wt% 2.5 g of sulfonated graphene was then added and uniformly dispersed in water after ultrasonic treatment, wherein the ultrasonic power was 150 W and the ultrasonic time was 40 min to obtain an aqueous phase solution with a volume of 20 mL. Pour the above aqueous phase solution into n-heptane preheated to 70°C, the water / oil volume ratio is 1:40, the addition amount of surfactant glyceryl monostearate is 2mL, and the The mixture was stirred and reacted for 120 minutes, then aged at a constant temperature of 70°C for 4 days, the graphene oxide composite microspheres were separated by standing, washed, and dried under normal pressure at 60°C. Then put the organic microspheres into a carbonization furnace, pass through argon protection, and carbonize at a constant temperature of 1300° C. for 1 hour to obtain ...

Embodiment 2

[0032] Embodiment 2: with glucinol (P), m-cresol (M), furfural (F), ammoniacal liquor (C) according to the molar ratio P:M:F=1:1:4, the ratio of P:C=300 , made into an aqueous solution with a solid content of 20wt%, then added 0.5g graphene oxide, and dispersed in water evenly after ultrasonic treatment, wherein the ultrasonic power was 100W, and the ultrasonic time was 60min, to obtain an aqueous phase solution with a volume of 10mL. Pour the above water phase solution into cyclohexane preheated to 60°C, the water / oil volume ratio is 1:10, the addition amount of surfactant span-20 is 8mL, and the reaction is stirred at a speed of 1400rpm / min 30 minutes, then aged at 60°C for 2 days, left to separate the graphene oxide composite microspheres, washed, and dried at 80°C under normal pressure. Then put the organic microspheres into a carbonization furnace, pass through nitrogen protection, and carbonize at a constant temperature of 700° C. for 4 hours to obtain graphene composite...

Embodiment 3

[0033] Embodiment 3: with resorcinol (P), melamine (A), formaldehyde (F), sodium bicarbonate (C) according to molar ratio P:A:G=1:2:7, P:C=1000 Ratio, made into an aqueous solution with a solid content of 40wt%, then added 1.5g of nitrogen-doped graphene, and dispersed in water evenly after ultrasonic treatment, wherein the ultrasonic power was 60W, and the ultrasonic time was 120min, to obtain an aqueous phase solution with a volume of 8mL. Pour the above water phase solution into the peanut oil which has been preheated to 100°C, the volume ratio of water / oil is 1:100, the volume ratio of surfactant glyceryl monostearate and span-80 is 1:2, and the total addition amount is 15mL, stirred and reacted for 60 minutes at a rotation speed of 2000rpm / min, then aged at a constant temperature of 100°C for 7 days, stood still to separate graphene oxide composite microspheres, washed, and dried under normal pressure at 20°C. Then put the organic microspheres into a carbonization furnace, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com