Preparation method for APET film with aroma

A film and fragrance technology, applied in the field of APET film preparation, can solve the problems of not being able to highlight the fashion features and performance characteristics of products, and achieve the effects of enriching film functionality, scientific implementation process, and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

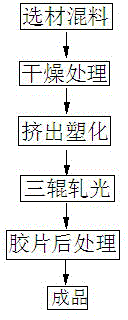

Image

Examples

Embodiment 1

[0017] The concrete preparation process of the APET film with fragrance that the present invention mentions is as follows:

[0018] a) Material selection and mixing, the main components of APET film and their percentage ratios are: polyethylene terephthalate 76%, fragrance microcapsules 18%, and the rest are related additives; among them, the fragrance microcapsules The average particle diameter is about 5-6um, and the core-capsule ratio is: 1:8; the outer wall of the fragrance microcapsule is a heat-resistant polymer material, and the heat-resistant temperature can reach about 300°C. In this embodiment, parylene is used, and the core material is It is a plant essence, which can have rose, jasmine, fragrance, osmanthus, chrysanthemum, ylang-ylang, freesia, freesia, violet and other fragrances; additives mainly include toughening agent EVA, anti-sticking agent PETG 67, antistatic agent SARMSTAT G33690, Denesting agent PET 9921, etc.; the mixing process is carried out in a centr...

Embodiment 2

[0024] The concrete preparation process of the APET film with fragrance that the present invention mentions is as follows:

[0025] a) Material selection and mixing, the main components of APET film and their percentage ratios are: polyethylene terephthalate 78%, fragrance microcapsules 17%, and the rest are related additives; among them, fragrance microcapsules The average particle diameter is about 5-6um, and the core-capsule ratio is 1:8; the outer wall of the fragrance microcapsule is made of heat-resistant polymer material, and the heat-resistant temperature can reach about 300°C. In this embodiment, polyimide is used, and the core material is It is a plant essence, which can have rose, jasmine, fragrance, osmanthus, chrysanthemum, ylang-ylang, freesia, freesia, violet and other fragrances; additives mainly include toughening agent EVA, anti-sticking agent PETG 67, antistatic agent SARMSTAT G33690, Denesting agent PET 9921, etc.; the mixing process is carried out in a cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com